Polishing monitoring method and polishing apparatus

一种设备、抛光垫的技术,应用在磨削/抛光设备、金属加工设备、表面抛光的机床等方向,能够解决不能频繁涡电流传感器校正、抛光设备可利用率下降等问题,达到精确膜厚度监视的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

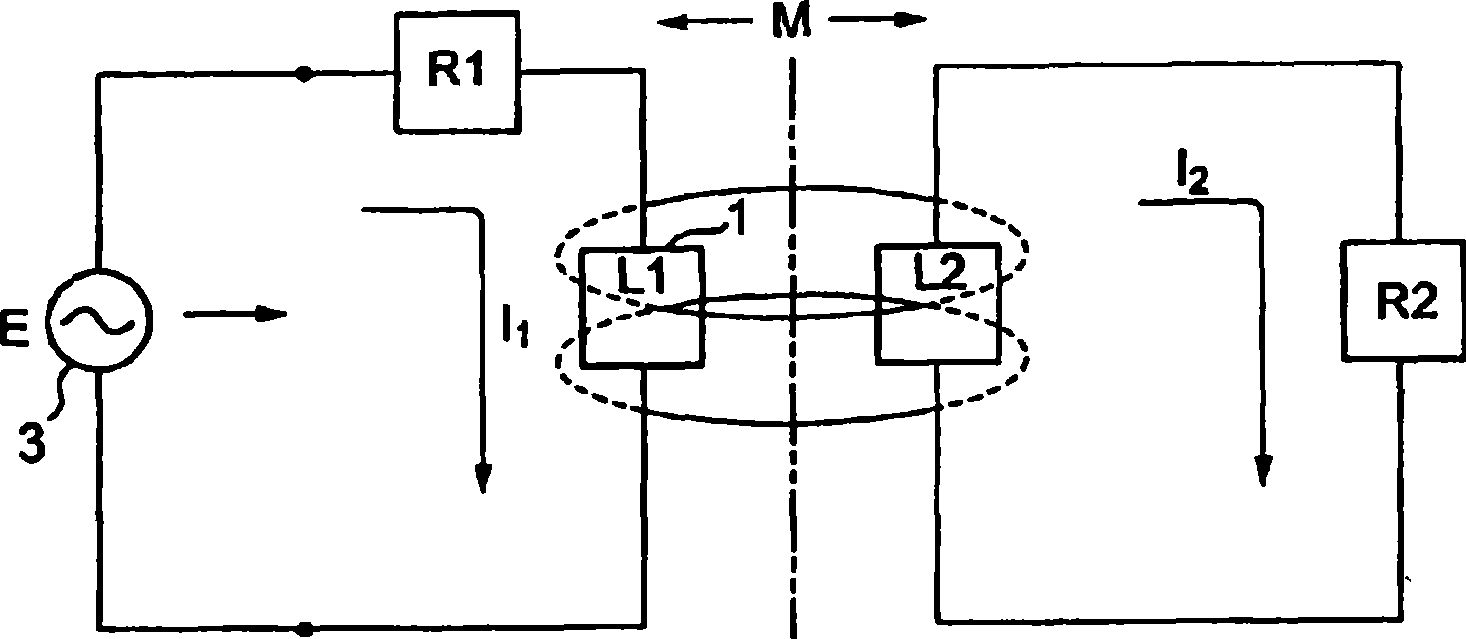

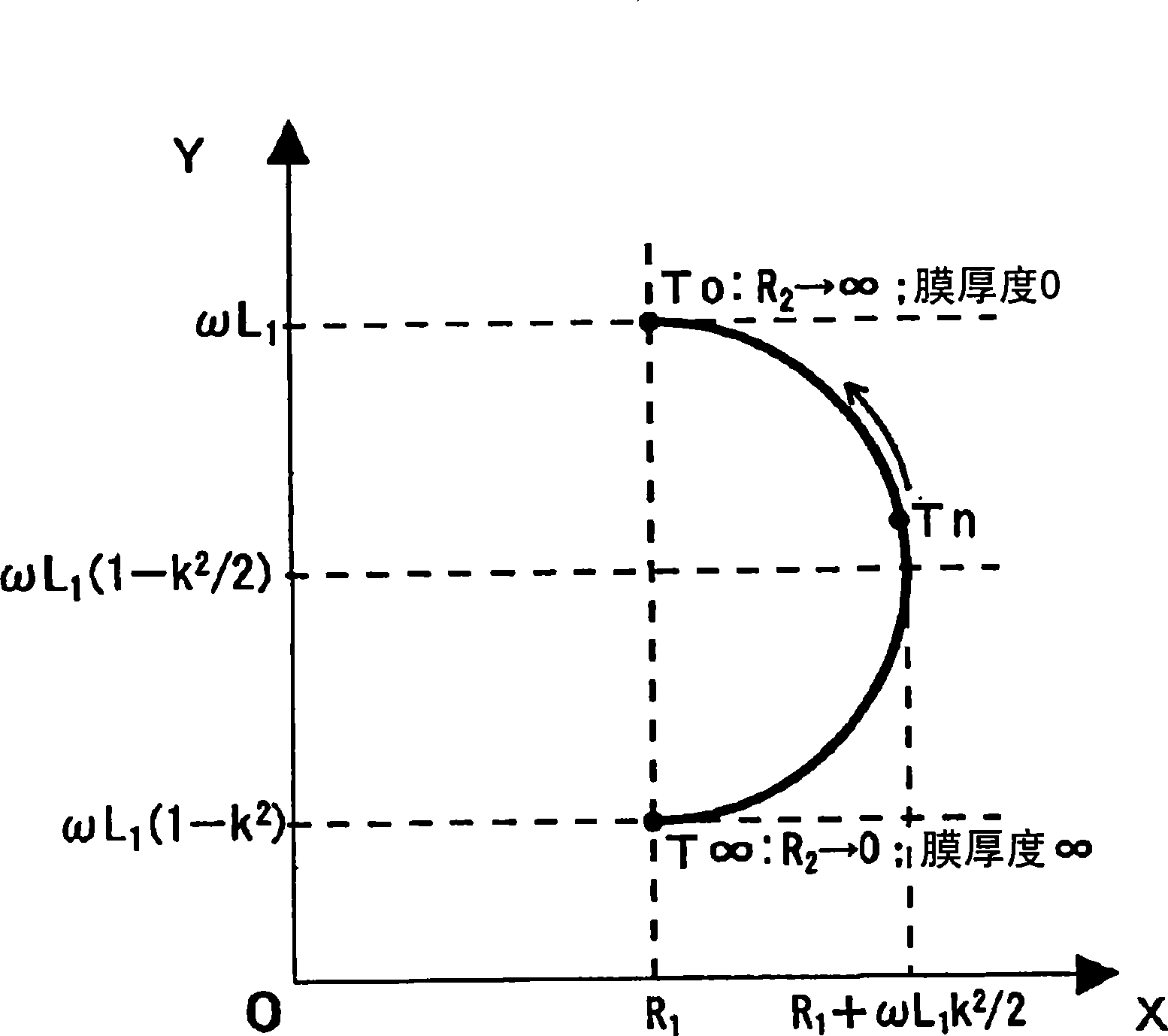

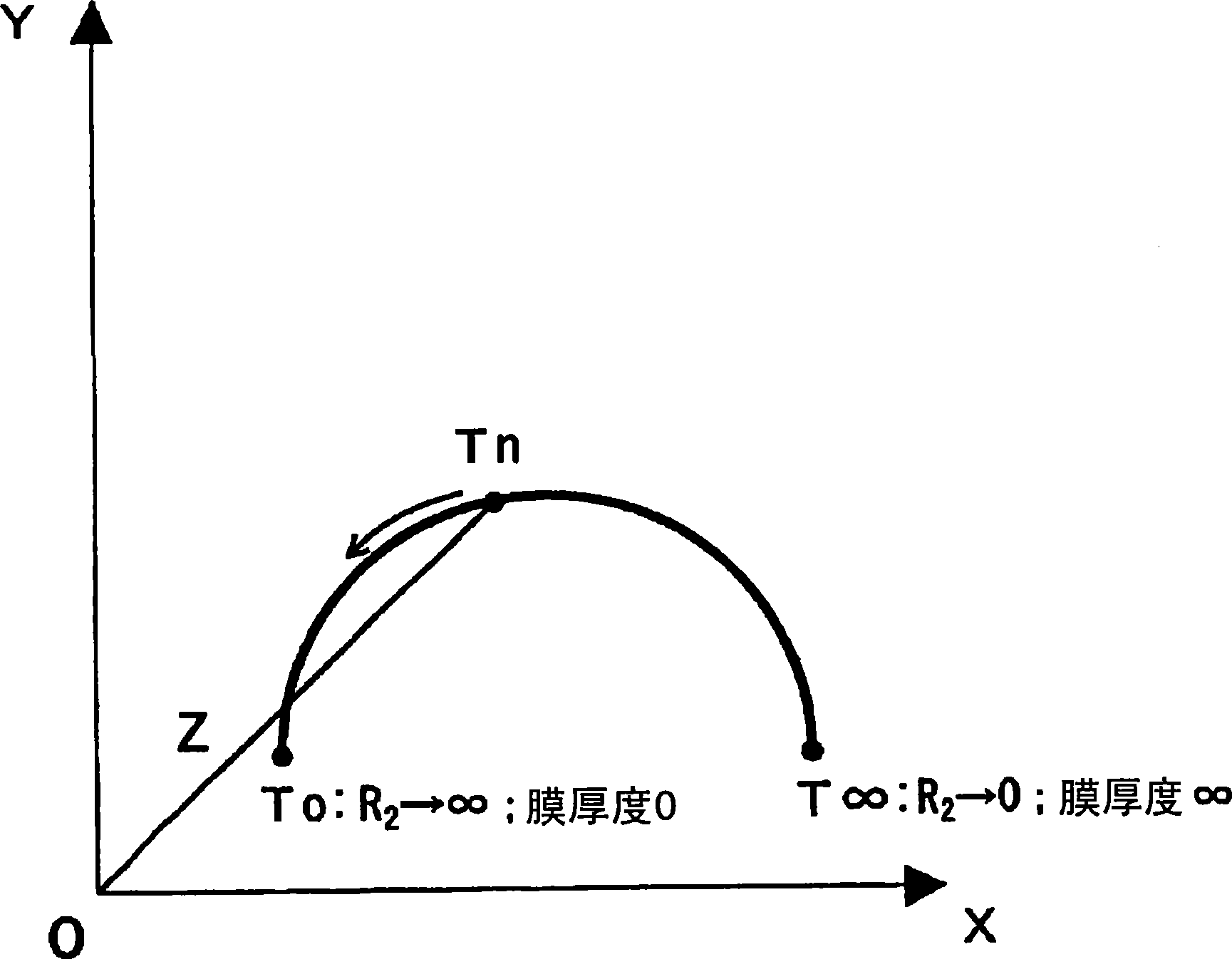

[0051] Embodiments of the present invention are described below with reference to the drawings.

[0052] Figure 7 is a schematic diagram of the overall structure of a polishing (grinding) device according to an embodiment of the present invention. as shown in Figure 7 , the polishing apparatus has a polishing table 12, which holds the polishing pad 10 on its upper surface, and a top ring 14, which is configured to hold a wafer (substrate) as a workpiece to be polished, and push the wafer against the surface of the polishing pad 10. on the upper surface, and a conditioner 20 configured to condition (or condition) the upper surface of the polishing pad 10 when polishing of the wafer is not being performed. The upper surface of polishing pad 10 provides a polishing surface for sliding contact with the wafer.

[0053] The polishing table 12 is connected to a motor (not shown) disposed below it, and is rotatable around its own axis as indicated by an arrow. A polishing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com