Caisson structure and method for smoothly and accurately sinking caisson structure into earth surface

A technology for caissons and shaft walls, which is applied in the direction of infrastructure engineering, caissons, buildings, etc., can solve problems such as insufficient rigidity, vertical tilting, and increased construction difficulty, so as to achieve less deformation or fracture, lower rigidity requirements, and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The caisson of the present invention and the method for accurately sinking the caisson into the ground will be described in detail below with reference to the accompanying drawings.

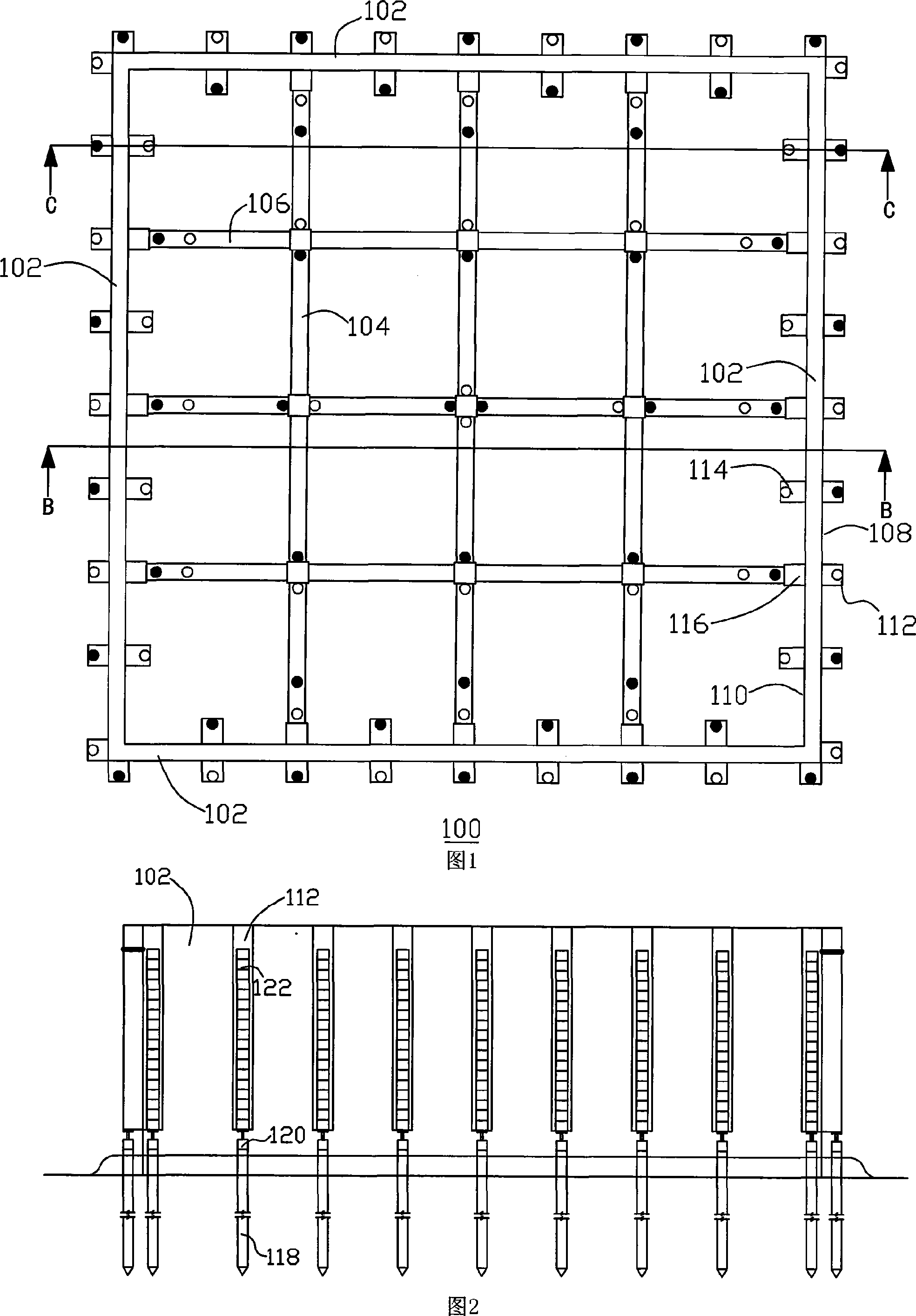

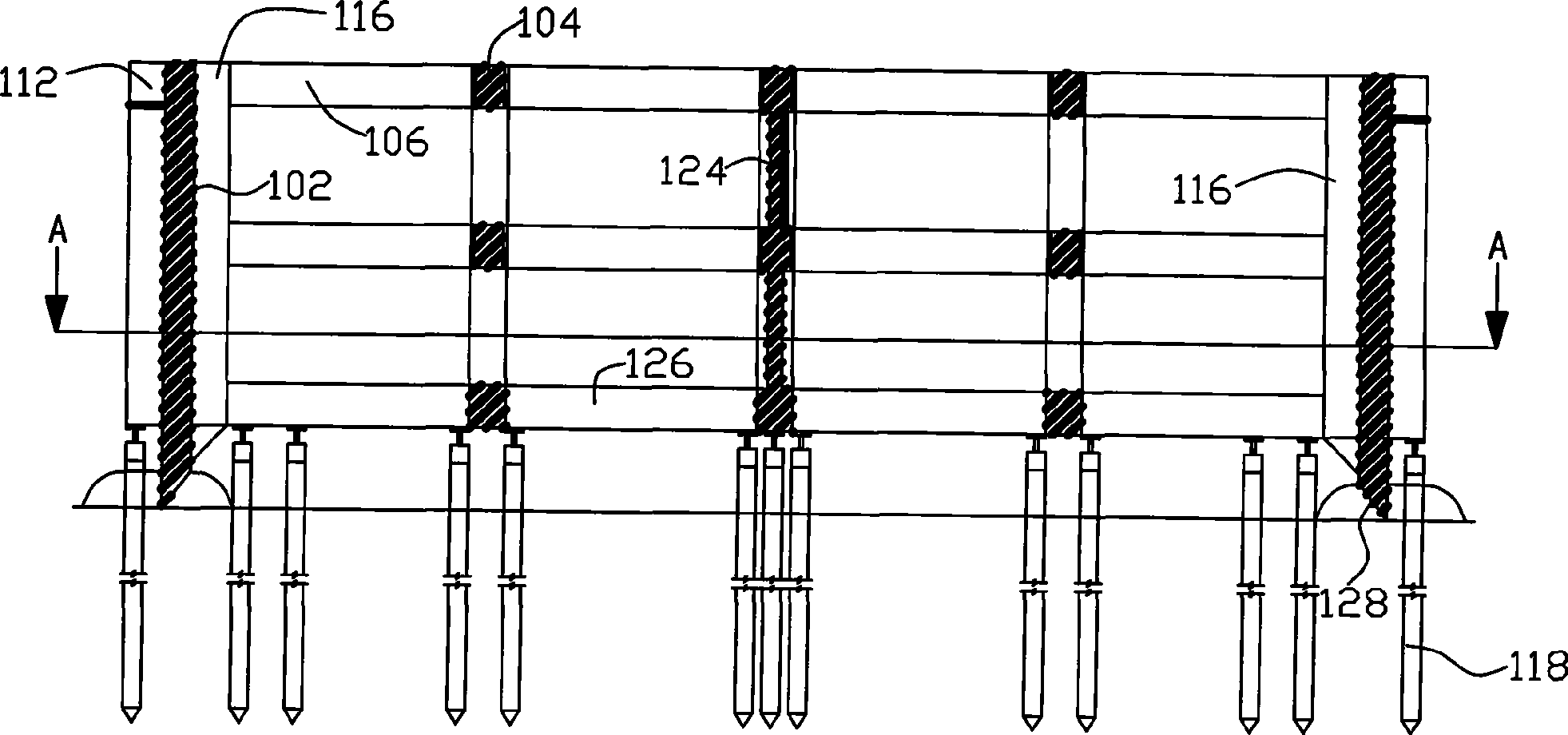

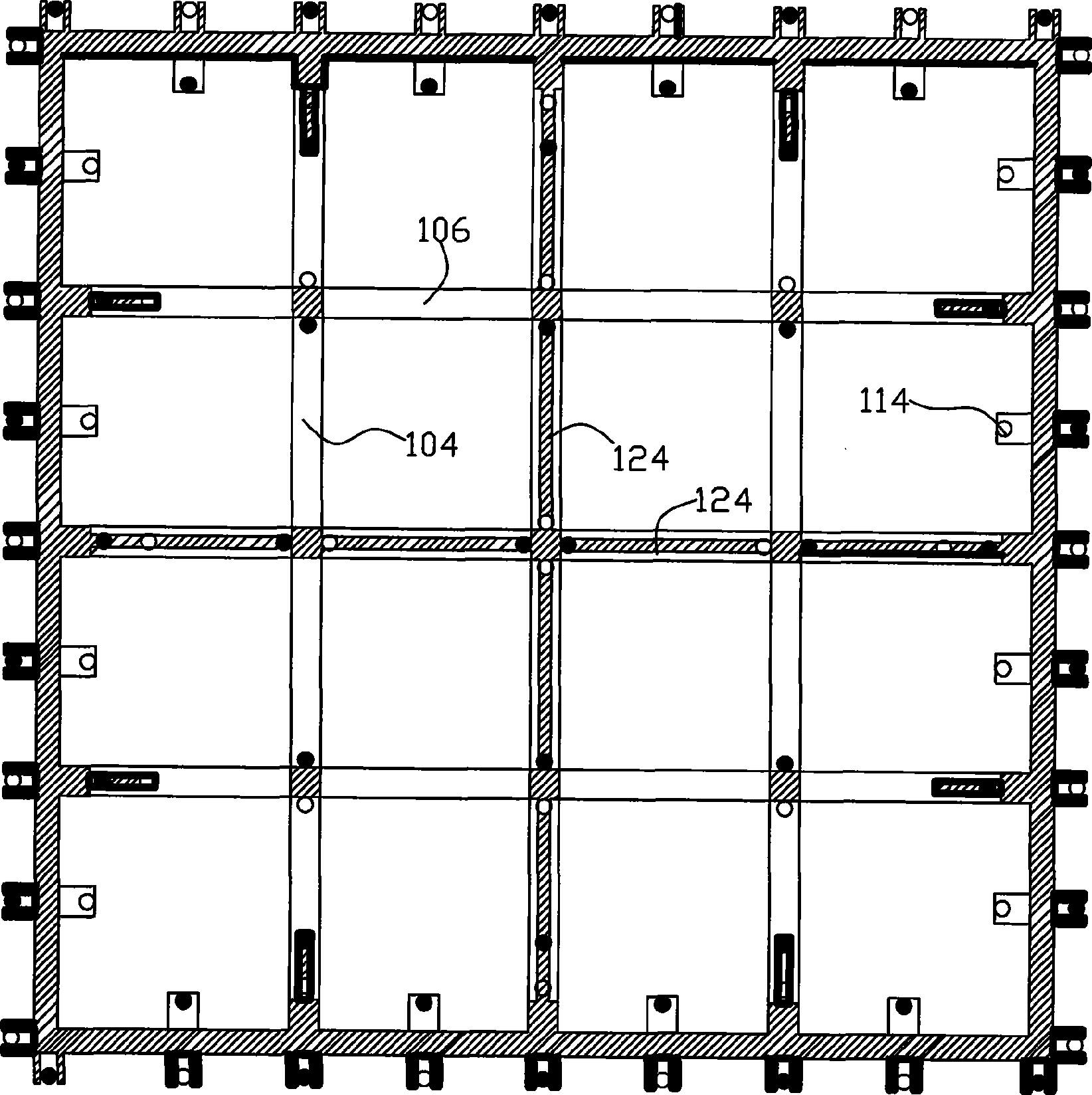

[0037] Firstly, the caisson structure of the present invention is introduced. 1-11 , the caisson 100 is generally a rectangular structure, such as a reinforced concrete structure or a steel structure. The caisson 100 includes four well walls 102 that are connected to each other so as to be closed, and any two opposite well walls 102 are parallel to each other, so that the four well walls 102 together form a rectangular shape. Each well wall 102 has an inner wall surface 110 and an outer wall surface 108 opposite to the inner wall surface 110 . A plurality of frame beams parallel to each other in the horizontal plane and the vertical plane are arranged between the inner wall surfaces 110 of any two opposing well walls 102 . For example, a frame stringer 104 can be arranged between two hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com