Power tool

A power tool and drive shaft technology, applied in the field of power tools, can solve the problems of complex structure, small holding surface, inconvenient operation, etc., and achieve the effects of safe and convenient operation, large holding surface and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

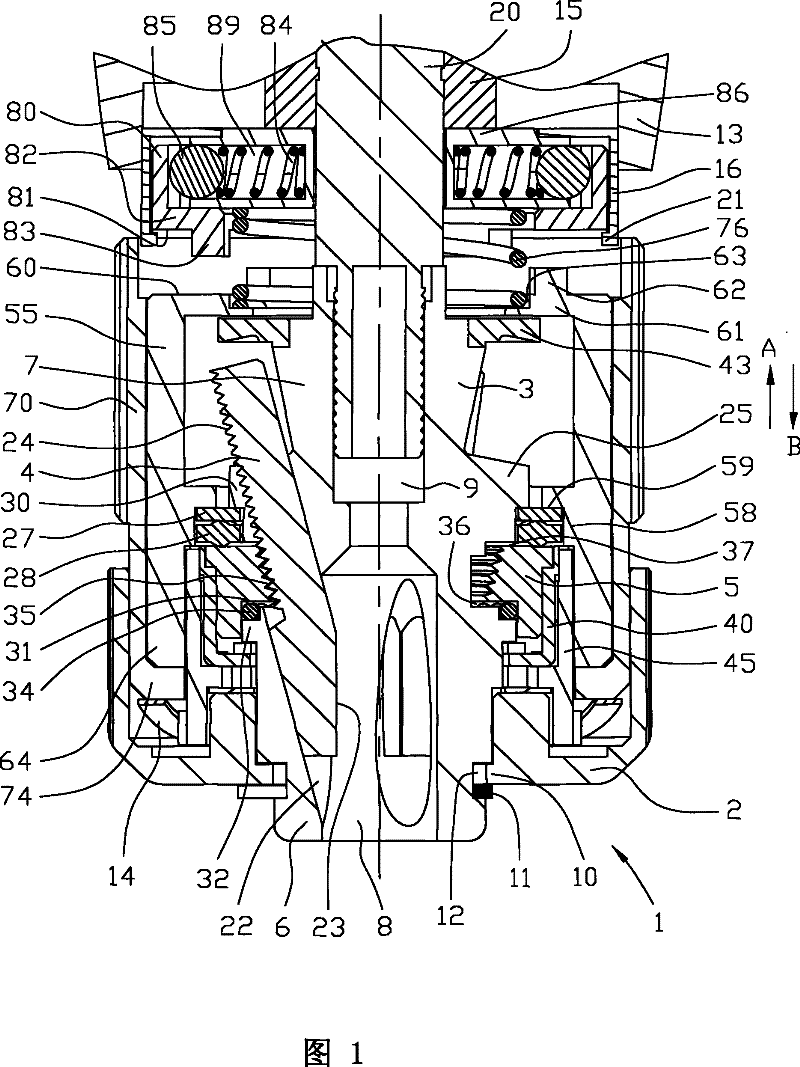

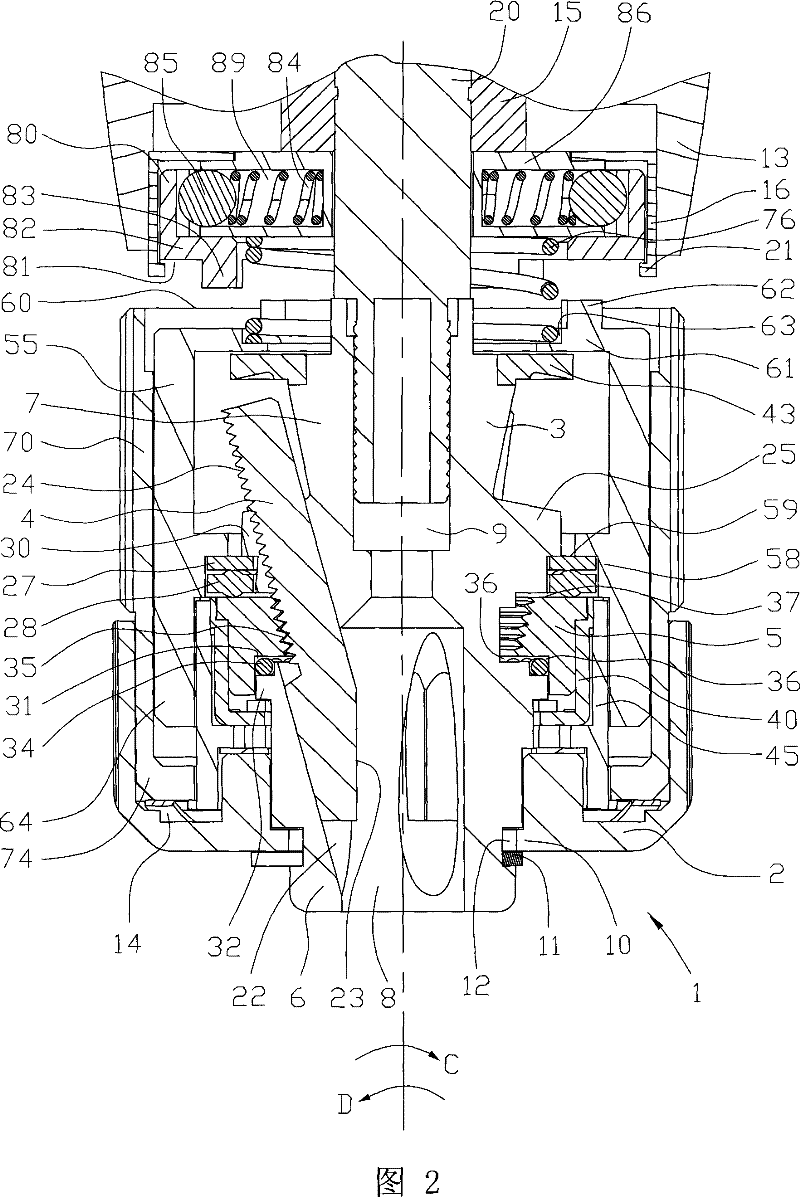

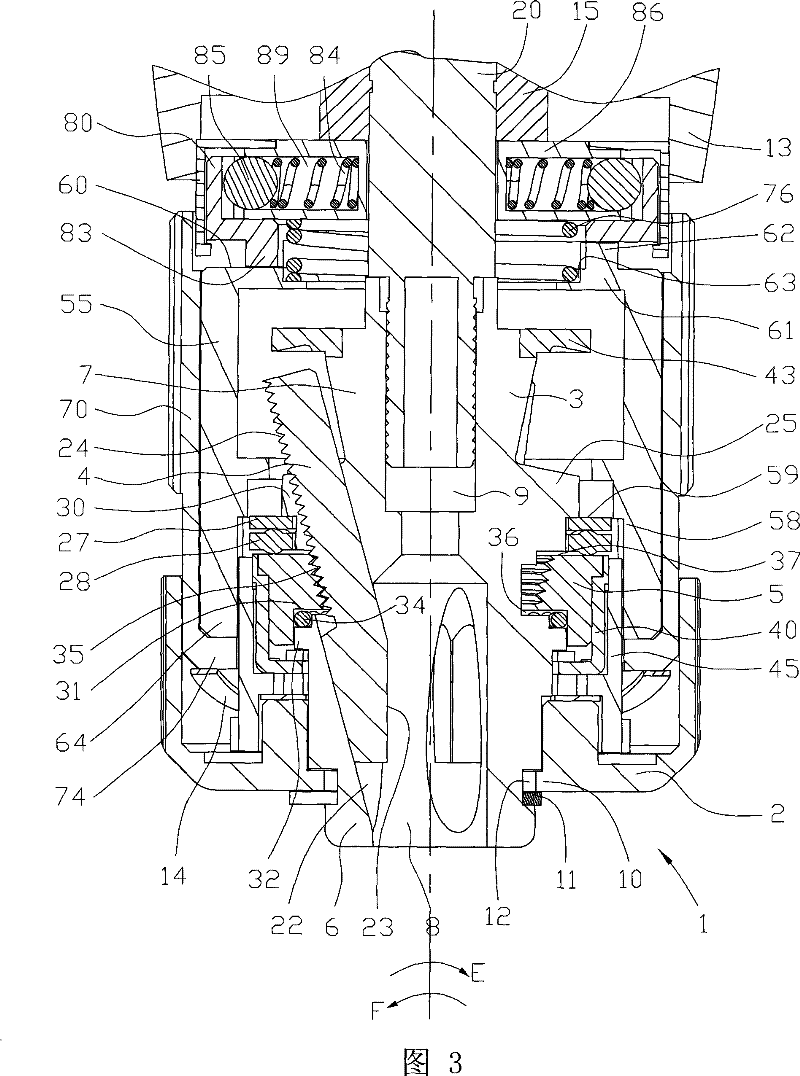

[0071] The present invention is preferred embodiment with electric drill. The electric drill has a casing 15 , a drive shaft 20 arranged in the casing, and a collet 1 installed on the drive shaft 20 .

[0072] refer to Figure 1 to Figure 5 As shown, in the first preferred embodiment of the present invention, the collet 1 has a second sleeve 2 , a central body 3 , jaws 4 and a nut 5 . The central body 3 is a central body with a front part 6 and a rear part 7 . In the front part 6 an axial hole 8 is formed, the diameter of which is larger than the maximum diameter of the tool shank held by the collet 1 . A columnar threaded hole 9 of standard size is formed in the rear part 7, and the threaded hole 9 cooperates with a columnar drive shaft 20 on the electric drill. The threaded hole 9 can also be a tapered hole of a standard size for matching with a tapered drive shaft 20 .

[0073] Three channels 22 arranged at an angle of 120° to each other are formed on the central body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com