Sanitary fitting

A technology for sanitary equipment and accessories, applied in mechanical equipment, engine components, valve devices, etc., can solve difficulties and other problems, and achieve the effect of comfortable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

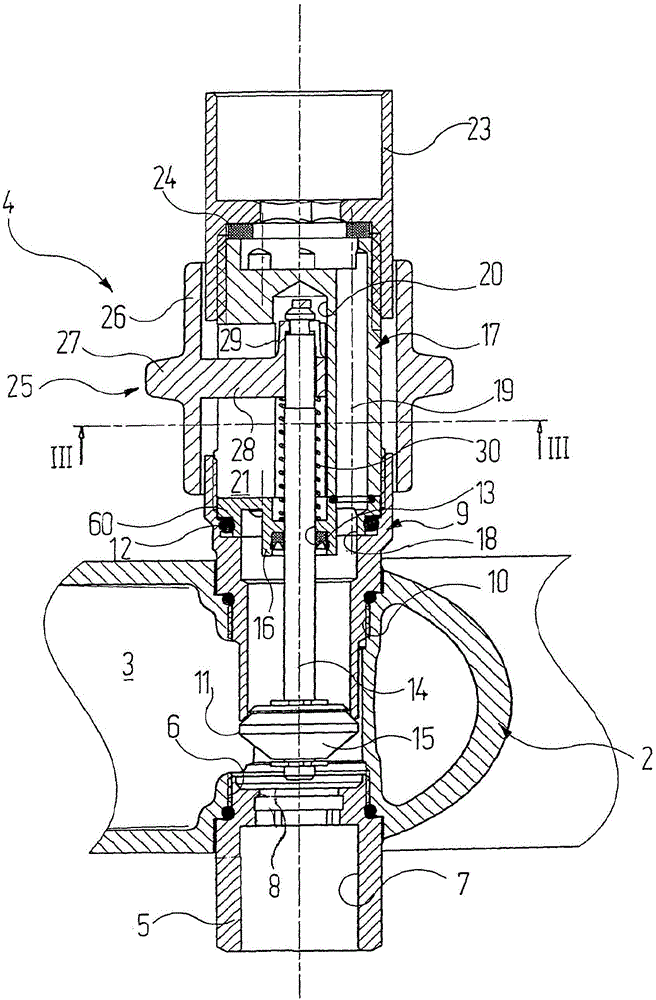

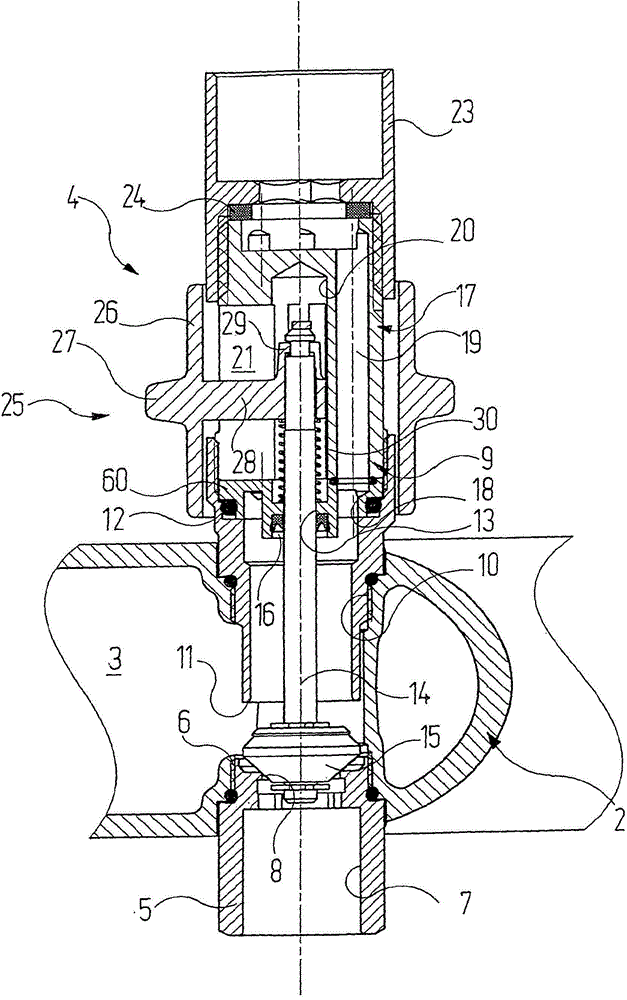

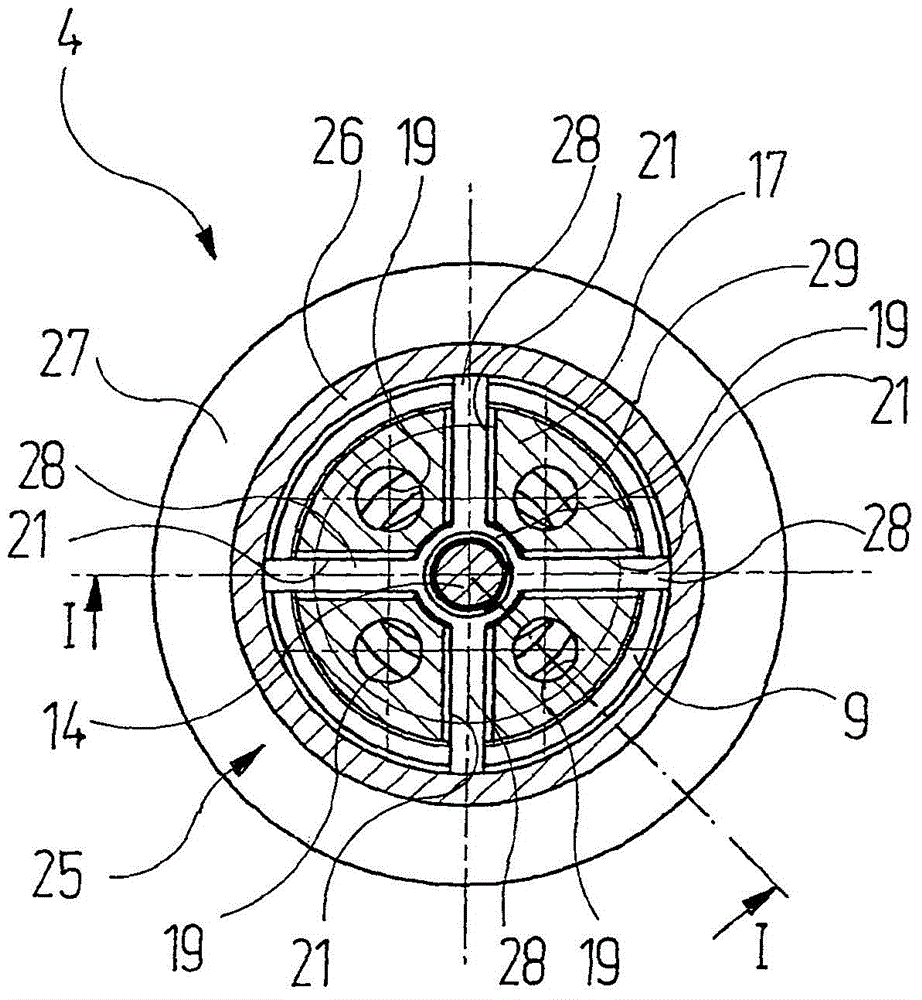

[0038] First refer to Figures 1 to 3 . There, a region of the housing 2 of the sanitary fitting is shown partially cut away. The types of plumbing fittings are in this example the same as below by means of Figures 4 to 9 The described embodiment is the same. It suffices to point out here that a water inflow chamber 3 is formed inside the housing 2 , via which water from, for example, a mixing valve or a thermostatic valve is conveyed to a switching device generally designated by the reference numeral 4 . The water flowing in through the water inflow chamber 3 can be guided selectively to one of the two water outlets by means of the switching device 4 .

[0039] In the exemplary embodiment shown, the first water outlet is formed by a pipe connection / connection sleeve 5 which is screwed into a threaded hole 6 of the housing 2 from below. The pipe connection 5 can be connected, for example, to a hose of a hand sprinkler. A first valve seat 8 is formed in the inner hole 7 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com