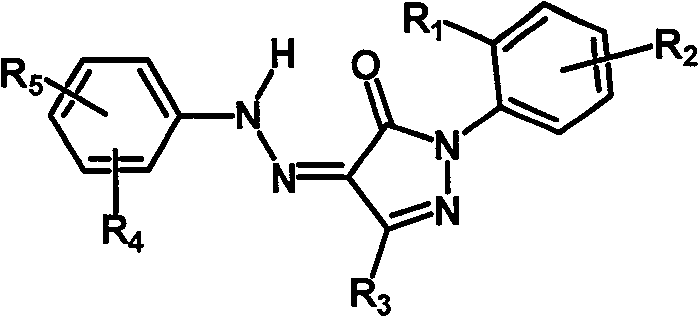

Azo structure carboxylic amide type dyes for polylactic acid fiber dyeing and preparation method thereof

A technology of polylactic acid fiber and carboxamide type, applied in the field of azo-structure carboxamide type dyes and its preparation, can solve the problems of poor dye uptake and color fastness, and achieve favorable dye uptake and color fastness , increase the dipole force, the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, a kind of preparation method of azo structure carboxamide type dyestuff for polyester fiber dyeing, carries out following steps successively:

[0039] 1) Add 3.2g of 1-phenyl-3-methyl-4-(4'-carboxyphenylhydrazone)-5-pyrazole into a three-necked flask equipped with a thermometer, reflux condenser and mechanical stirring device Linone, 20ml benzene, 0.2ml DMF, 2.2ml thionyl chloride, heated to 60°C, reacted for 2h;

[0040] 2) After the reaction is complete, heat the reaction liquid to 90°C, evaporate excess thionyl chloride and solvent under reduced pressure, cool to room temperature, transfer to ice water, filter, wash with ice water until the filtrate is neutral, and dry in vacuum After obtaining the carboxylic acid chloride intermediate;

[0041] 3) In a three-neck flask equipped with a stirrer, a thermometer, and a condenser tube, first add 3.4g of carboxylic acid chloride intermediate and 25ml of acetone as a solvent, and after the carboxylic acid chl...

Embodiment 2

[0043] Embodiment 2, a kind of preparation method of azo structure carboxamide type dyestuff for polyester fiber dyeing, carry out following steps successively:

[0044] 1) Add 6.4g of 1-phenyl-3-methyl-4-(4'-carboxyphenylhydrazone)-5-pyrazole into a three-necked flask equipped with a thermometer, reflux condenser and mechanical stirring device Linone, 60ml benzene, 0.6ml DMF, 6ml thionyl chloride, heated up to 55°C, and reacted for 6h;

[0045] 2), with embodiment 1;

[0046] 3), add 3.4g carboxylic acid chloride intermediate and 25ml of acetone as solvent in the there-necked flask equipped with agitator, thermometer and condenser, after the carboxylic acid chloride intermediate is dissolved in acetone, add 0.87g n-pentylamine and 1.38g powdered K 2 CO3, mixed and stirred at room temperature for 1 hour;

[0047] 4), with embodiment 1, obtain carboxyl n-pentylamine type dye.

Embodiment 3

[0048] Embodiment 3, a kind of preparation method of azo structure carboxamide type dyestuff for polyester fiber dyeing, carry out following steps successively:

[0049] 1) Add 6.4g of 1-phenyl-3-methyl-4-(4'-carboxyphenylhydrazone)-5-pyrazole into a three-necked flask equipped with a thermometer, reflux condenser and mechanical stirring device Linone, 50ml benzene, 0.8ml DMF, 5.5ml thionyl chloride, heated up to 55°C, reacted for 3h;

[0050] 2), with embodiment 1;

[0051] 3), first add 3.4g of carboxylic acid chloride intermediate and 25ml of acetone as solvent in the there-necked flask equipped with agitator, thermometer and condenser tube, after the carboxylic acid chloride intermediate is dissolved in acetone, then add 1.0g of n-hexylamine and 2.5 g powdered K 2 CO 3 , mixed and stirred at room temperature for 1 hour,

[0052] 4), with embodiment 1, get carboxyl n-hexylamine type dye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com