Ph automatic continuous detection device

A detection device and automatic technology, applied in the field of electrochemical detection, can solve the problems of broken glass head, complicated operation process, and inability of liquid to flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

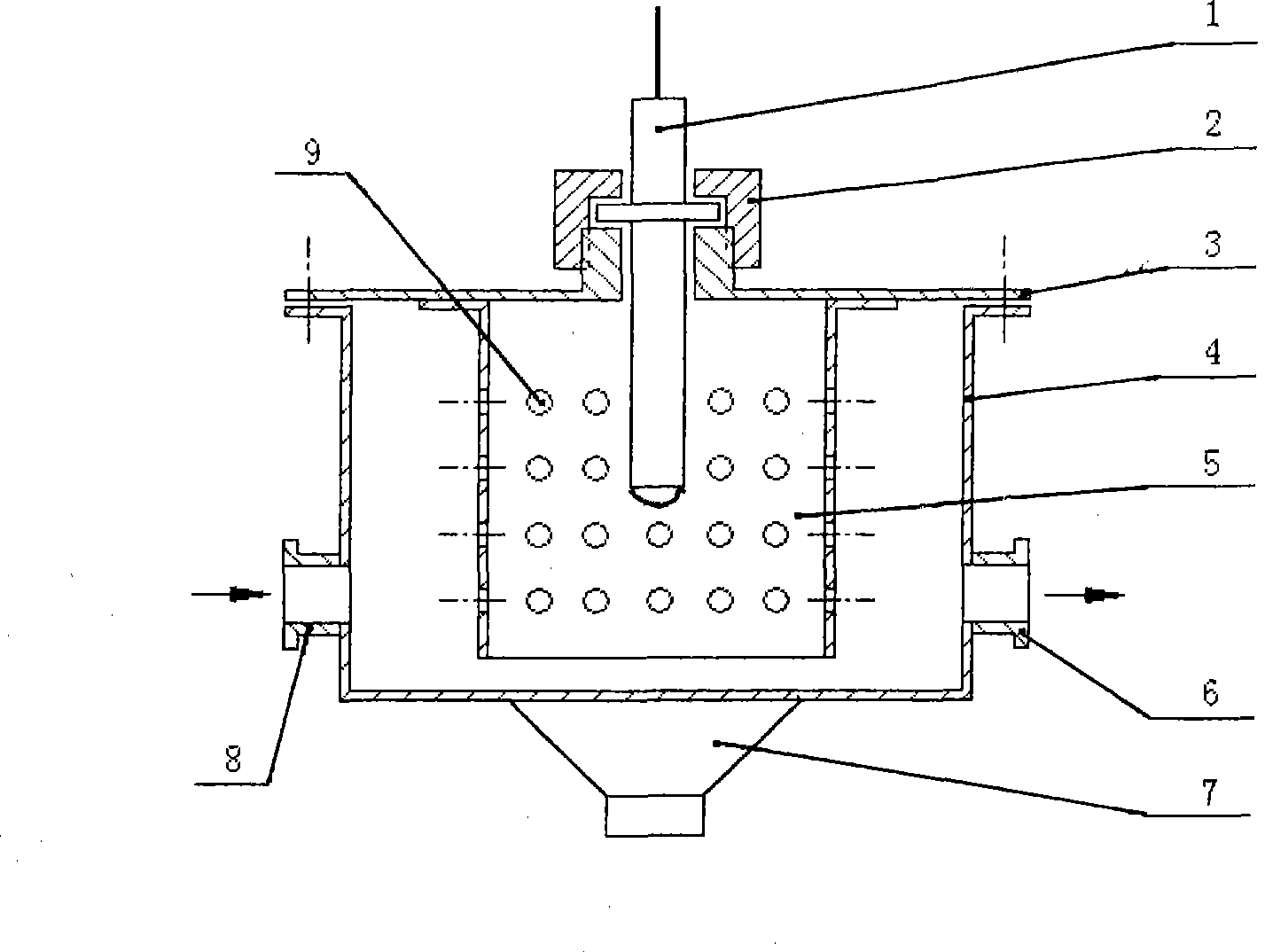

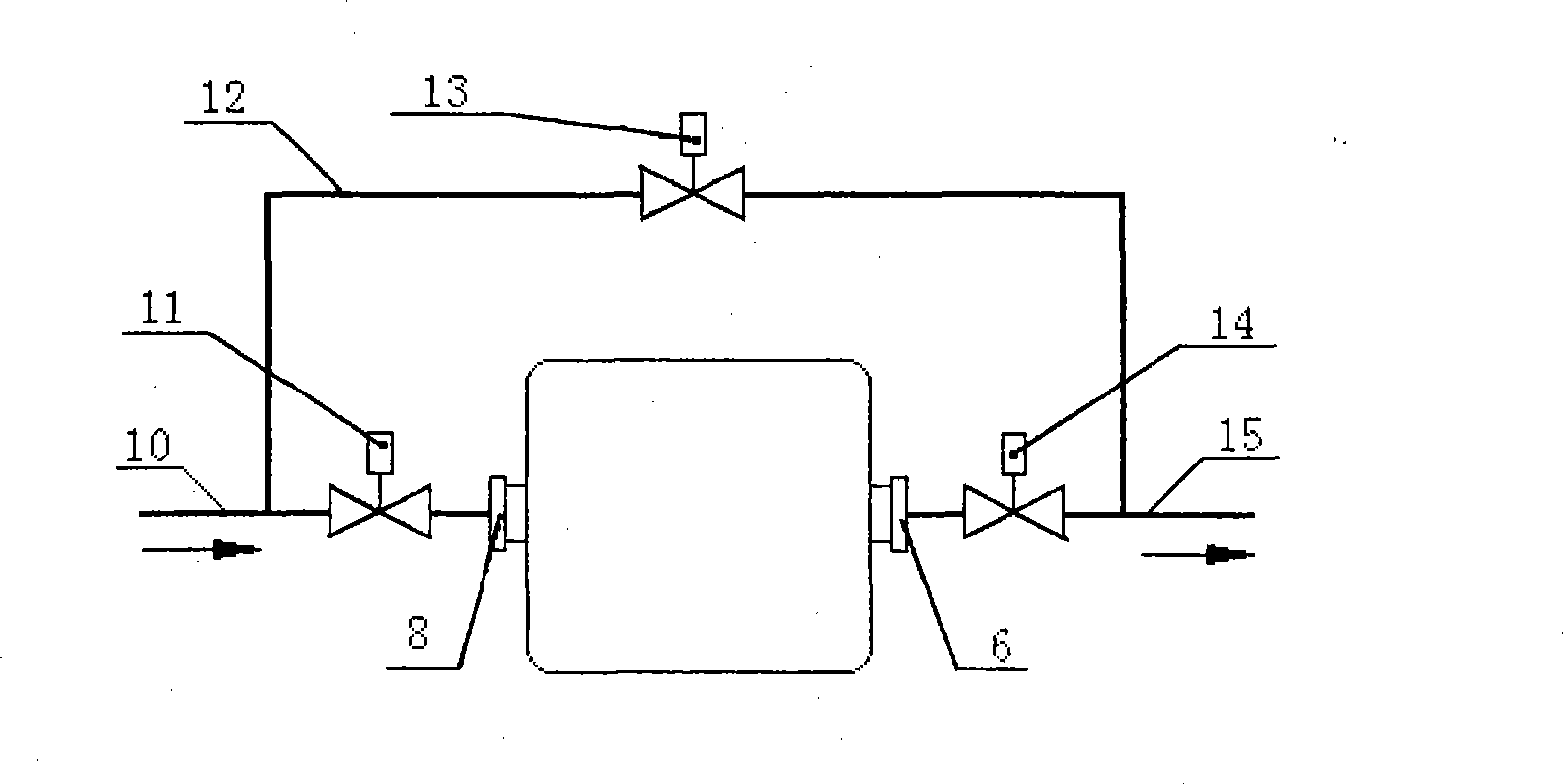

[0009] Such as figure 1 As shown, the detection part of the pH automatic continuous detection device includes a detection tank 4, the lower part of the side wall of the detection tank 4 is provided with a corresponding liquid inlet 8 and a liquid outlet 6, and the top of the detection tank 4 is provided with a cover plate 3, An ultrasonic generator 7 is arranged at the bottom of the detection tank 4 corresponding to the position of the pH glass detection electrode 1 . A stabilizing cover 5 is arranged in the detection tank 4, and the stabilizing cover 5 is a cylindrical body with both ends open, and a liquid hole 9 is opened on its side wall. The detected liquid enters the detection tank 4 from the liquid inlet 8, flows out from the liquid outlet 6, and needs to pass through the liquid hole 9 when passing through the steady flow cover 5, so as to realize a stable flow rate. One end of the flow stabilization cover 5 is fixed under the cover plate 3, and the inner cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com