Method for demarcating small-scale vision measuring video camera based on composite planar target drone

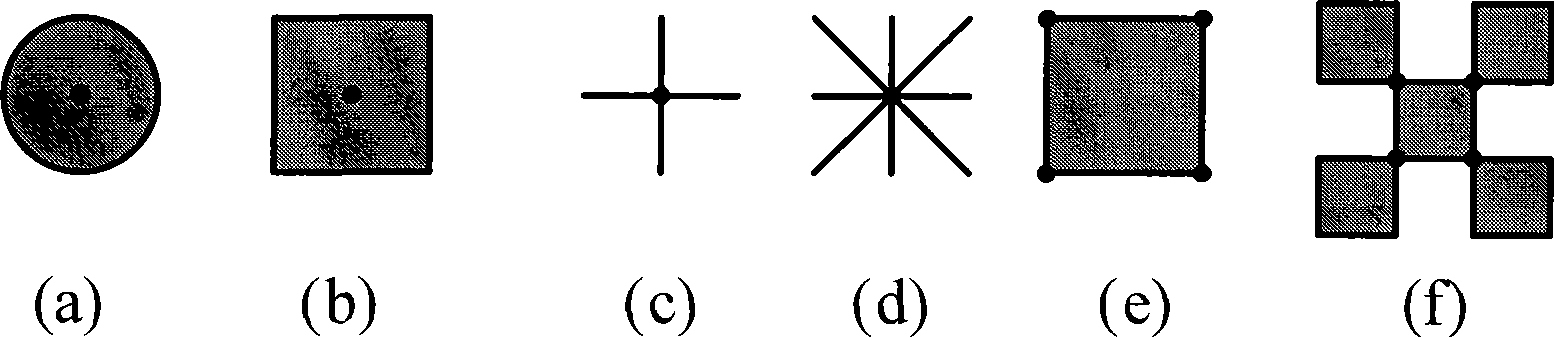

A camera calibration and planar target technology, applied in the field of visual measurement, can solve the problems of high processing difficulty and high processing cost, and achieve the effects of simple processing, improved use efficiency, and easy processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

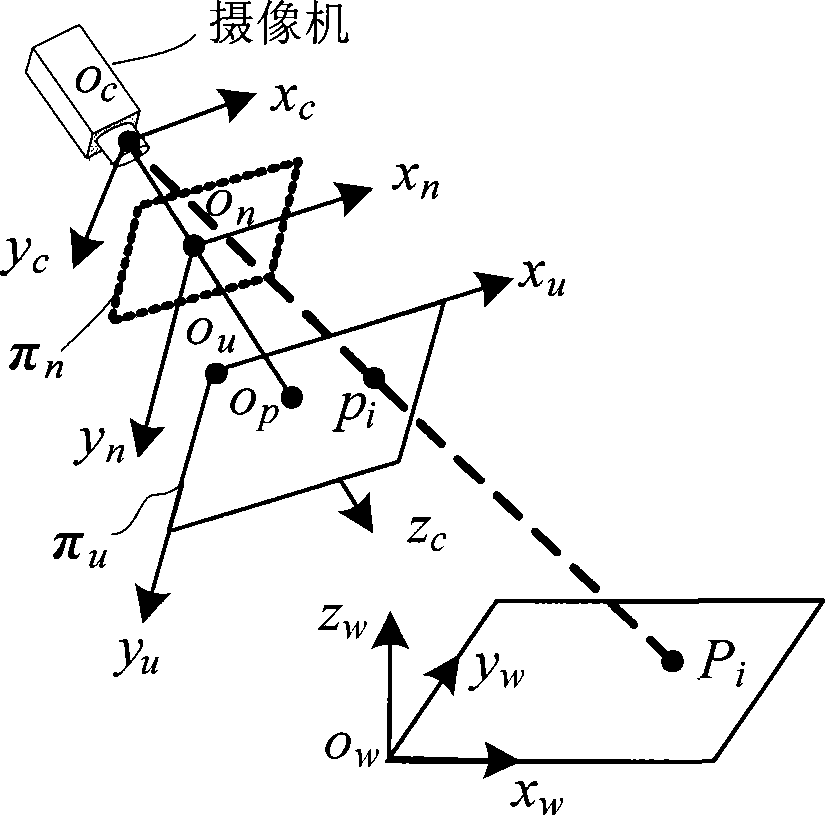

Method used

Image

Examples

Embodiment

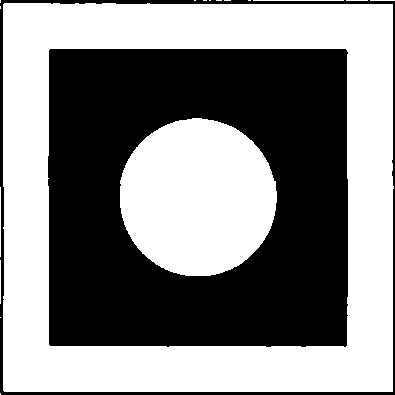

[0054] Figure 4 It is a schematic diagram of the calibration point generated by the composite planar target of the present invention. A high-precision composite planar target is produced by coating and etching on optical glass. The side length of the black square of the target is 9mm, the diameter of the round spot is 5mm, and the precision is 0.005mm. For the composite target made, the world coordinate system is established with the upper left corner of the grid as the origin, the x-axis in the horizontal direction, and the y-axis in the vertical downward direction, and the world coordinates of all calibration points on the target are calculated, as shown in Table 1.

[0055] Table 1 The world coordinates of the marked points on the target (unit: mm)

[0056]

[0057] Table 2 The image coordinates of the extracted points on the target (unit: pixel)

[0058]

[0059] The image coordinates of the points corresponding to the target plane feature points are shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com