Impact resistant knee joint structure

A knee joint and impact-resistant technology, applied in the field of knee joint structure, can solve problems such as the gap in impact resistance function, and achieve the effect of preventing knee flexion and slowing down the reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

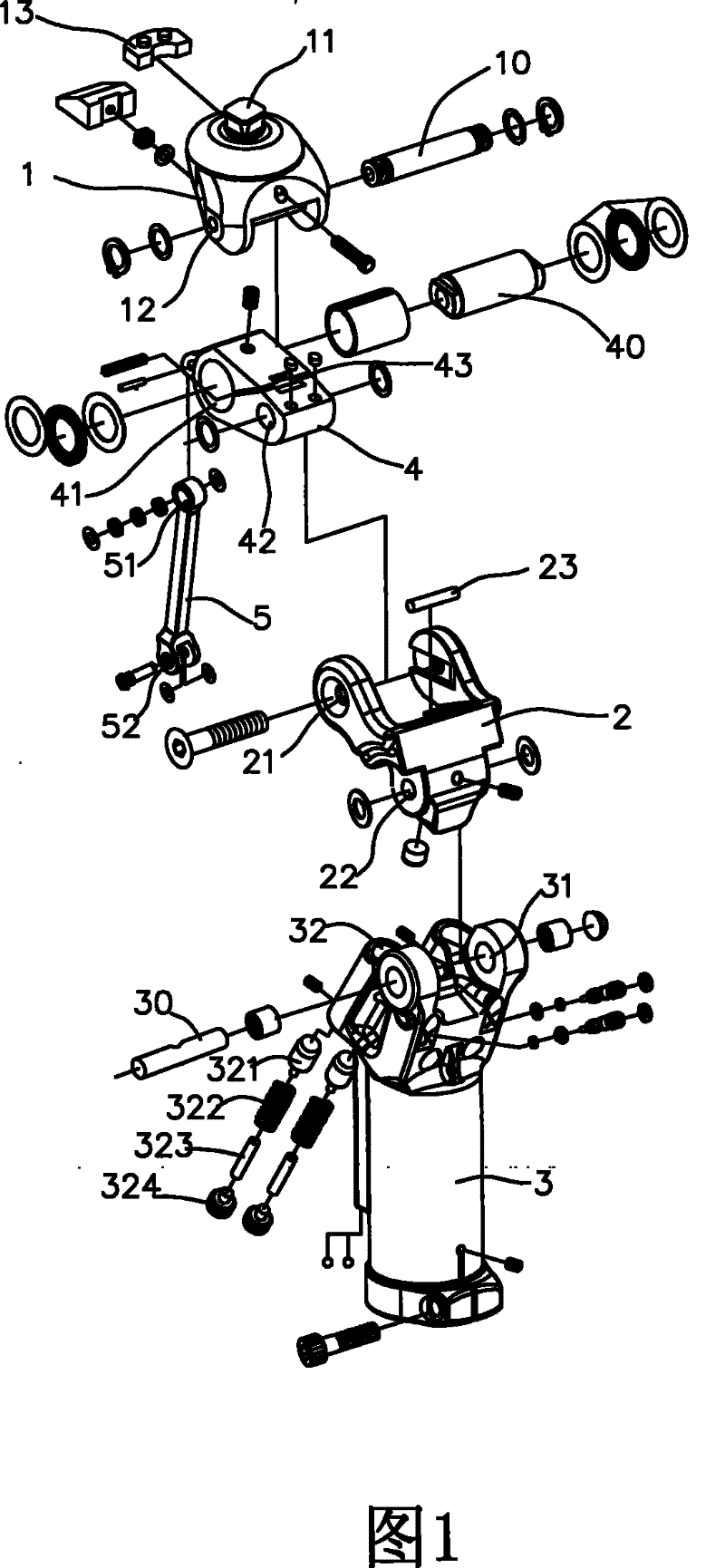

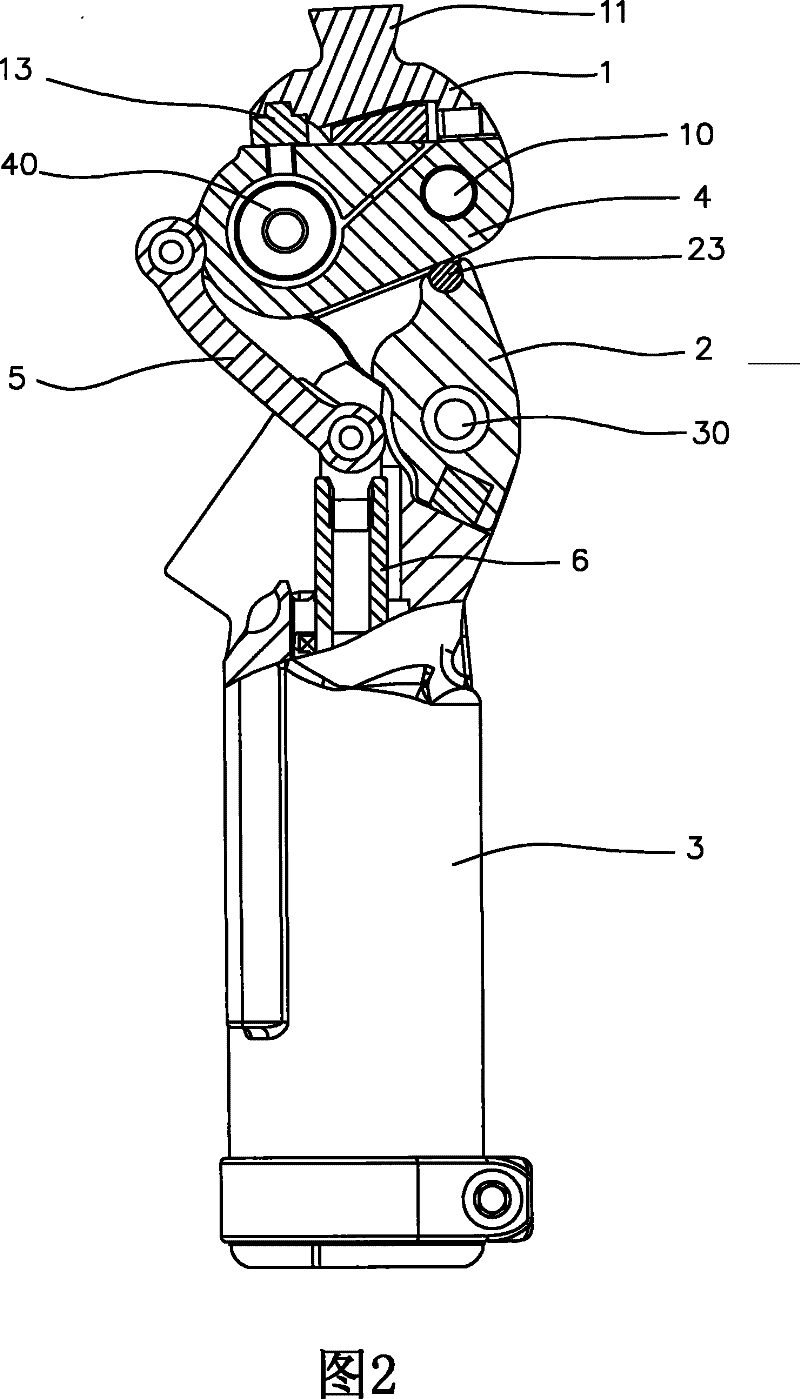

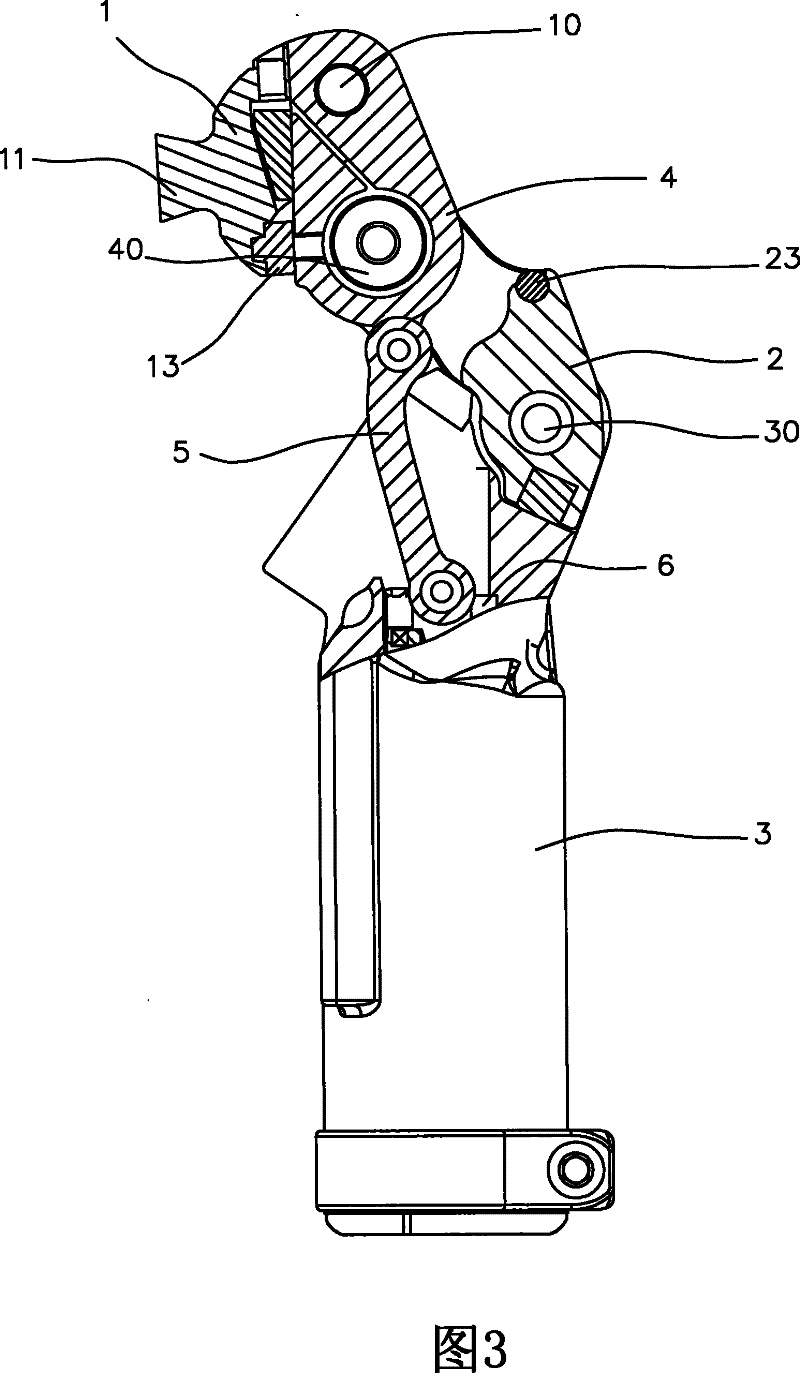

[0017] Hereinafter, with respect to the structure and function of the present invention, a preferred feasible embodiment is adopted, and after cooperating with the drawings in detail, to increase the understanding of the present invention; the present invention is a kind of impact-resistant knee joint structure, please refer to as Figure 1 to Figure 6 As shown, the main structure includes the upper link 1, the middle link 2, the lower pneumatic cylinder housing 3, the axial brake block 4, the pneumatic tie rod 5 and the pneumatic cylinder assembly 6, wherein;

[0018] See how figure 1 As shown, the upper end of the upper link 1 is provided with a connector 11, which can be used to fix the thigh to the connector 11 with several bolts. Linkage piece perforation 12, the middle shaft center 40 is pierced through the upper piercing hole 21 of the middle section linkage piece 2 and the shaft center piercing hole 41 of the shaft center brake block 4, and the lower section shaft cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com