Bending, fusing, softening method for fluorescent lamp finned coil

A technology for bending fluorescent lamp sheets and tubes, which is applied in glass reshaping, glass manufacturing equipment, and glass molding. Pass rate, reduce sagging and drop, and increase the effect of counterweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

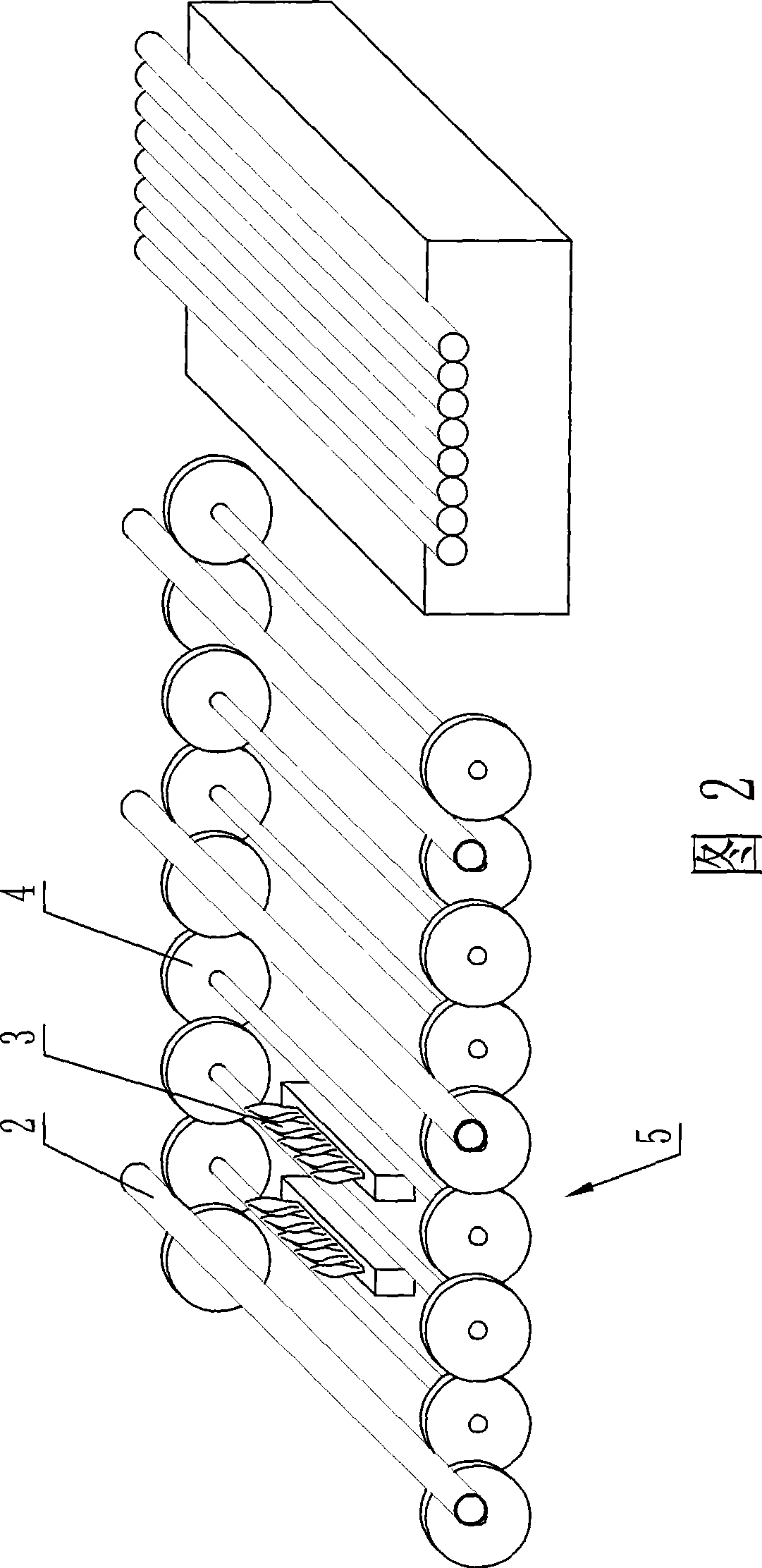

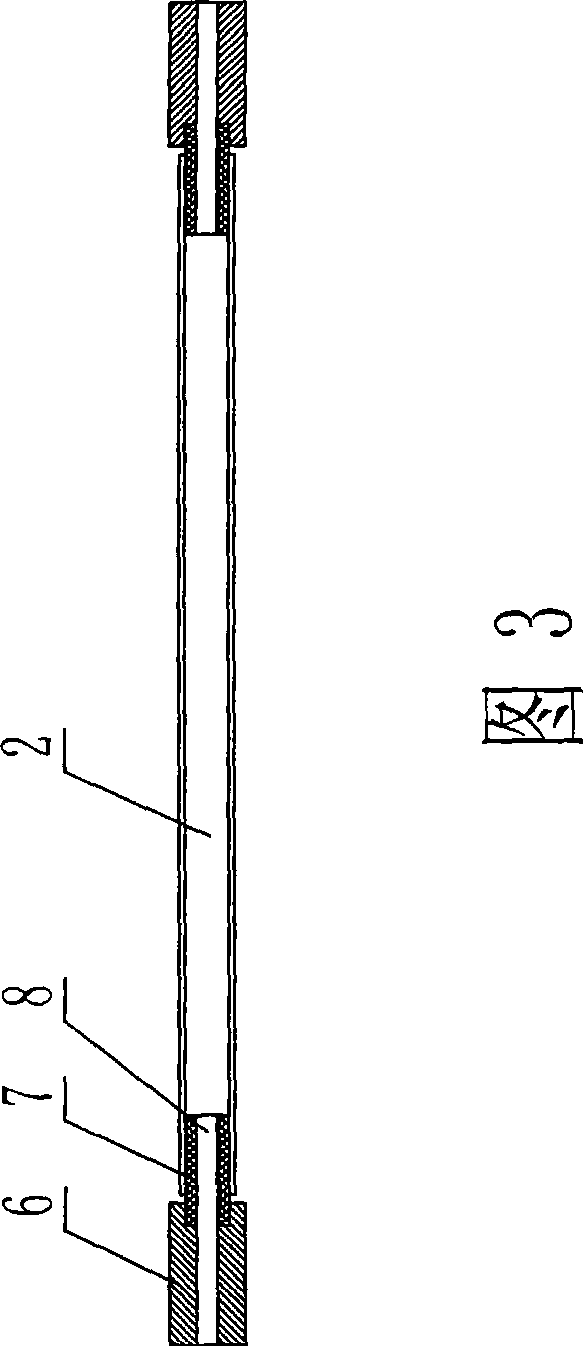

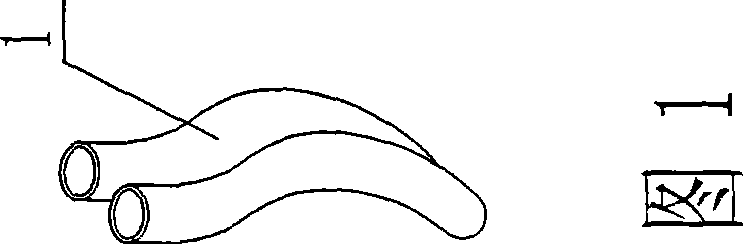

[0013] Embodiment: Referring to Figures 2 and 3, the method for bending, melting, and softening fluorescent lamp tubes according to the present invention is to first fix the two ends of the glass tube 2 with the required actual length, and insert a metal counterweight equipped with a foamed silicone rubber conical joint 7 Section 6, the counterweight section and the plug connector have axial through holes 8, and the outer diameter of the whole counterweight section is approximately similar to the outer diameter of the fused glass tube. Put the glass tube equipped with the counterweight section into the melting and softening device 5, and be transported one by one by the rolling conveying device 2 supported at both ends, and melted by the melting flame 3 until softened. Finally, it is bent and formed by the bending device, and the counterweight segment is removed after forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com