Seal stopper used for electrography equipment and processing box using the same

An electronic imaging and sealing plug technology, which is applied in the field of sealing plugs and processing boxes, can solve problems such as poor sealing effect, inconvenient use, and damage to the sealing plug, so as to avoid damage to the sealing plug, increase the sealing effect, and not be easily damaged Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

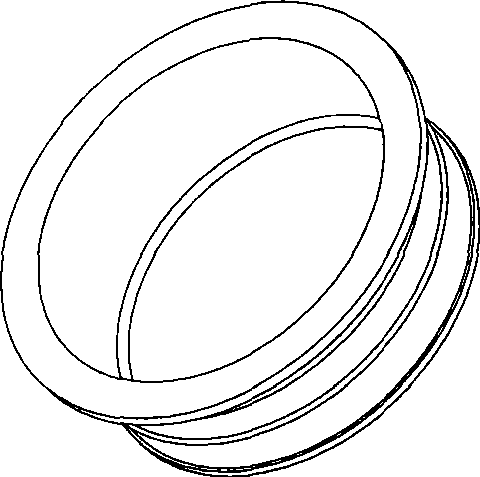

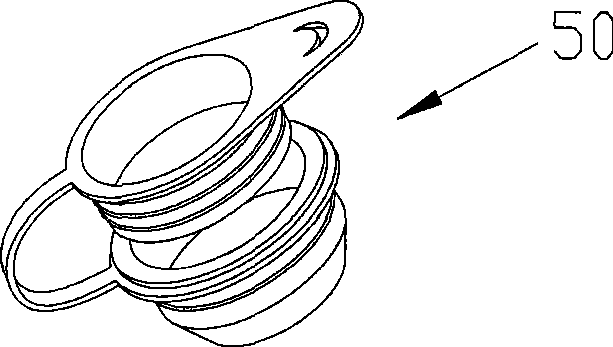

[0040] Such as Figure 3-8 As shown, a sealing plug 50 used in an electronic imaging device is composed of a plug body 501 , a plug sleeve 502 and a connecting piece 503 . The plug body 501 is provided with a handle 5012; the outer circumference of the plug body 501 and the plug sleeve 502 are respectively provided with an annular protrusion 5011 and an annular protrusion 5021, and the cross section of the plug body 501 is "U" shape; and the lower half 502b, the upper half 502a is a hollow cylinder, and the lower half 502b is a hollow truncated cone. Assuming that the maximum cross-sectional diameter of the plugged hole is S1, and the maximum cross-sectional diameter of the annular protrusion 5021 on the plug sleeve 502 is S2, then S2 is 0.1 mm to 1 mm larger than S1, and 0.3 mm to 0.5 mm is the best; assuming the plug sleeve The maximum cross-sectional diameter of the inner circumference of 502 is S3, the maximum cross-sectional diameter of the annular protrusion 5011 on the...

Embodiment 2

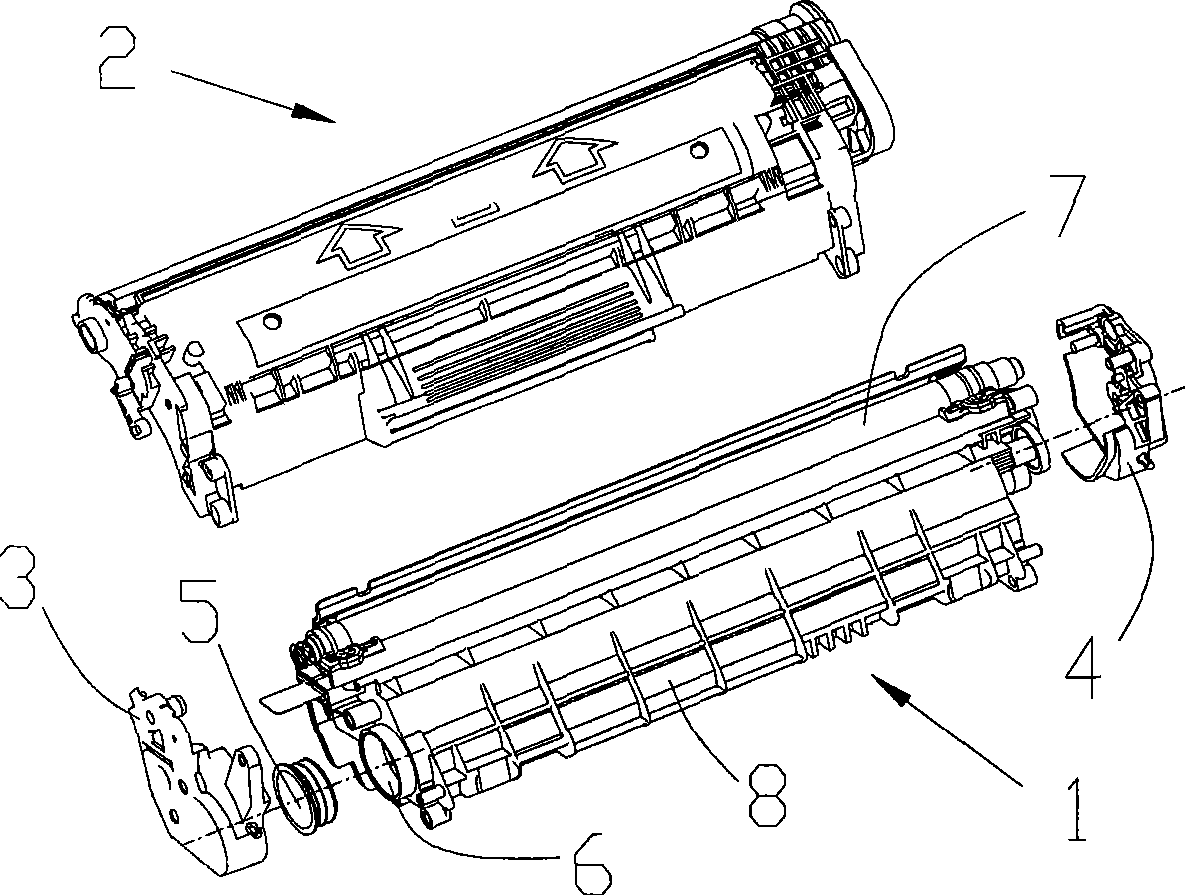

[0047] A process box includes: a developing unit 10 , a photosensitive unit 20 , a first side plate 30 , a second side plate 40 and a sealing plug 50 . The developing unit 10 includes at least a housing 80 and a developing element 70 ; the photosensitive unit 20 includes at least one photosensitive element; The developing unit 10 can store developer. There is also a developer inlet 60 on the developing unit 10. The sealing plug 50 completely adopts the sealing plug structure in the first embodiment. The avoidance opening avoids the installation area of the sealing plug 50. In the state where the photosensitive unit 20, the developing unit 10, and the side plates 30, 40 are fully assembled, powder is added to the housing 80 through the developer inlet 60, and then the inlet 60 is sealed with the sealing plug 50, thereby realizing the process cartridge. filling and refilling. When filling the process cartridge with developer for the first time, the filling procedure is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com