Ball hinge series rubber elastic element rigidity-changing method and ball hinge series rubber elastic element

A technology of elastic components and rubber elastic bodies, applied in low internal friction springs, springs/shock absorbers, springs made of plastic materials, etc., can solve problems such as sudden changes in stiffness, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

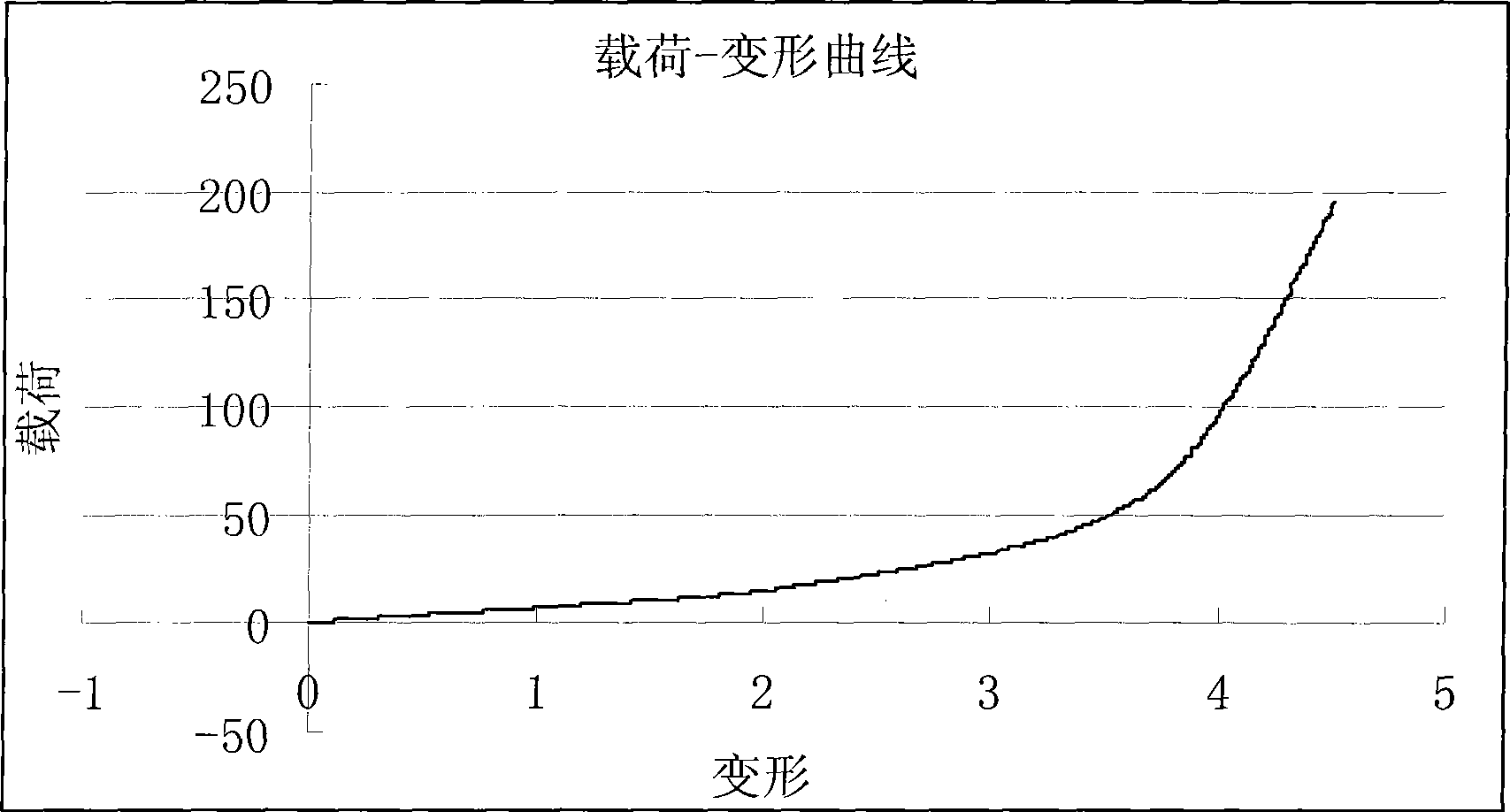

[0031] Fig. 4 and 5 have provided a specific embodiment of the present invention, can find out by accompanying drawing, the present invention is a kind of ball hinge type rubber elastic element, comprises metal jacket 1, elastic rubber body 2, mandrel 3, elastic rubber The body 4 and the jacket 5 are characterized in that: the rubber elastic element is a four-petal structure, the metal jacket and the rubber elastic body are four petals, and the two form a group, and the opposite two form a group to form a Y The two groups of spherical hinge rubber elastic bodies in the direction and the X direction are perpendicular to each other. In the free state, the four-petal metal jacket has a certain gap along the circumferential direction; among them, the metal jacket 1 in the Y direction and the elastic rubber body 2 are completely vulcanized together, but The metal jacket 5 in the X direction is separated from the rubber elastic body 4 in the X direction, and there is a certain gap Δ ...

Embodiment 2

[0036] Figure 6 and 7 Another specific embodiment of the present invention is given. The structure of the second embodiment is similar to that of the first embodiment, except that a metal spacer is added between the vulcanized body jacket and the mandrel in the Y direction, and the number of spacers can be adjusted as required. Compared with Embodiment 1, greater radial stiffness can be obtained in the Y direction, and the stiffness of the two stages in the X direction will also increase.

Embodiment 3

[0038] Figure 8 and 9 Another specific embodiment of the present invention is given. The structure of embodiment three is similar to that of embodiment one, except that a metal spacer is added between the metal jacket and the mandrel in the X direction, and the number of spacers can be adjusted as required. In the first embodiment, greater radial stiffness can be obtained in the X direction, and the stiffness in the two stages in the Y direction will also increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com