Cathode carbon block and cathode structure of impervious barrier conductive steel rod

A technology of conductive steel rod and cathode carbon block, which is applied to the cathode structure of aluminum electrolytic cell, cathode carbon block and conductive steel rod of anti-seepage layer, can solve the problem that the change range of the cross section of the cathode steel rod is not large and it is difficult to maximize the It can improve the current distribution in the molten aluminum and the cathode carbon block, and achieve the effect of improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

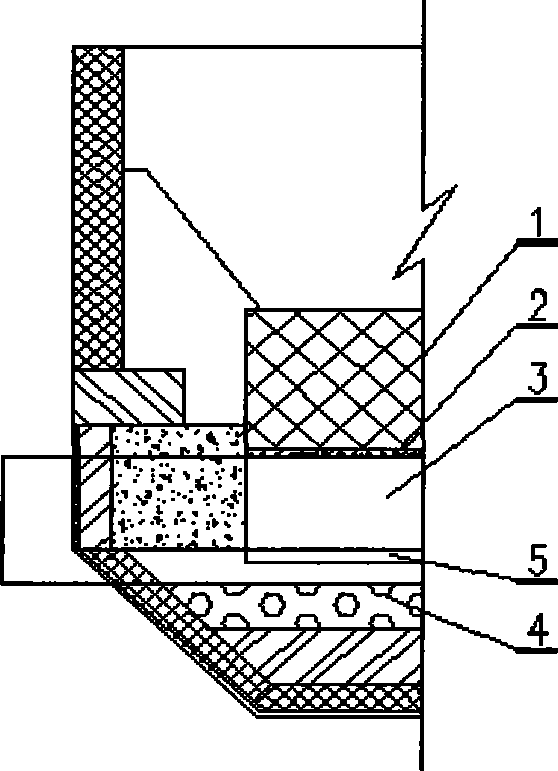

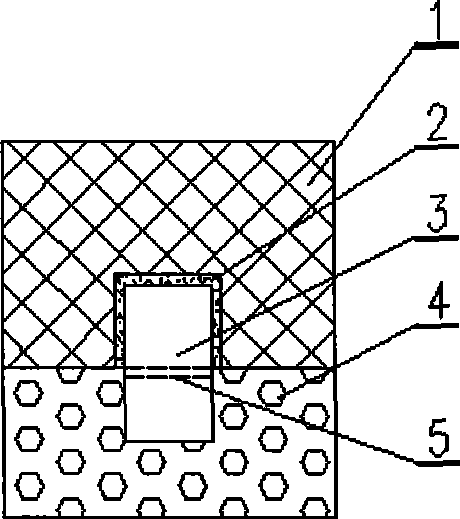

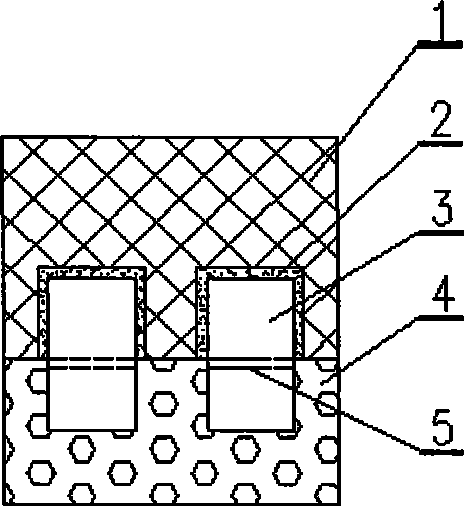

[0025] Such as figure 1 Shown, the cathode structure of a kind of cathode carbon block and anti-seepage layer conductive steel rod of the present invention comprises electrolyzer cathode carbon block 1, cathode ramming paste or phosphorus iron 2, conductive steel rod 3 and anti-seepage layer 4; The conductive steel rod is located between the cathode carbon block and the anti-seepage layer. The bottom of the cathode carbon block is provided with a steel rod groove that matches the shape of the conductive steel rod. The outer side of the steel rod is the side of the electricity outlet direction, and the side of the electricity outlet direction of the conductive steel rod is provided with a gap 5, and the gap partially separates the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com