Sluice plate type airtight door

A technology of airtight doors and gates, which is applied in the field of airtight doors, can solve the problems of large installation position, complex mechanical structure, and large overall volume, and achieve the effect of uniform force and satisfactory installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

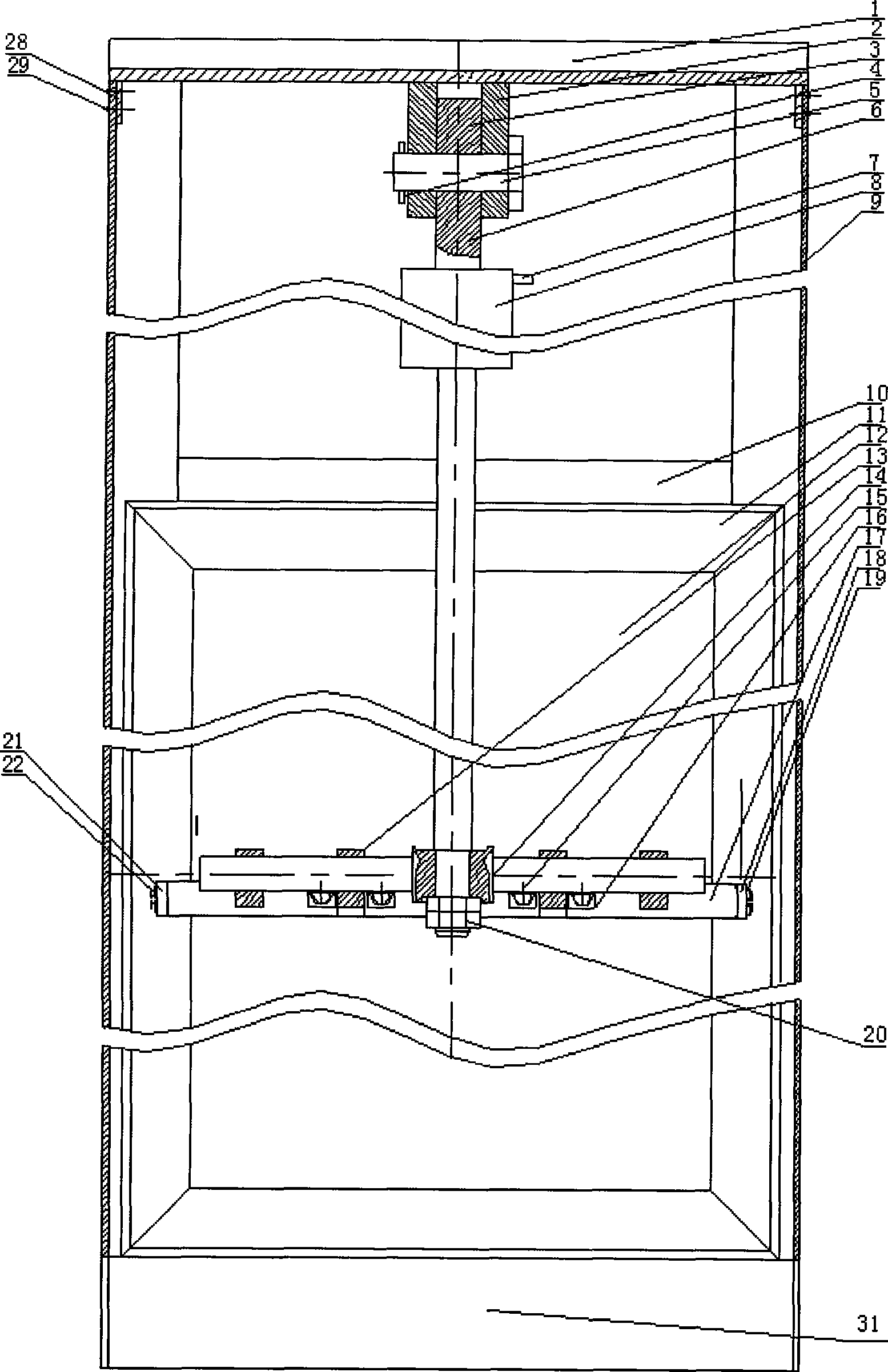

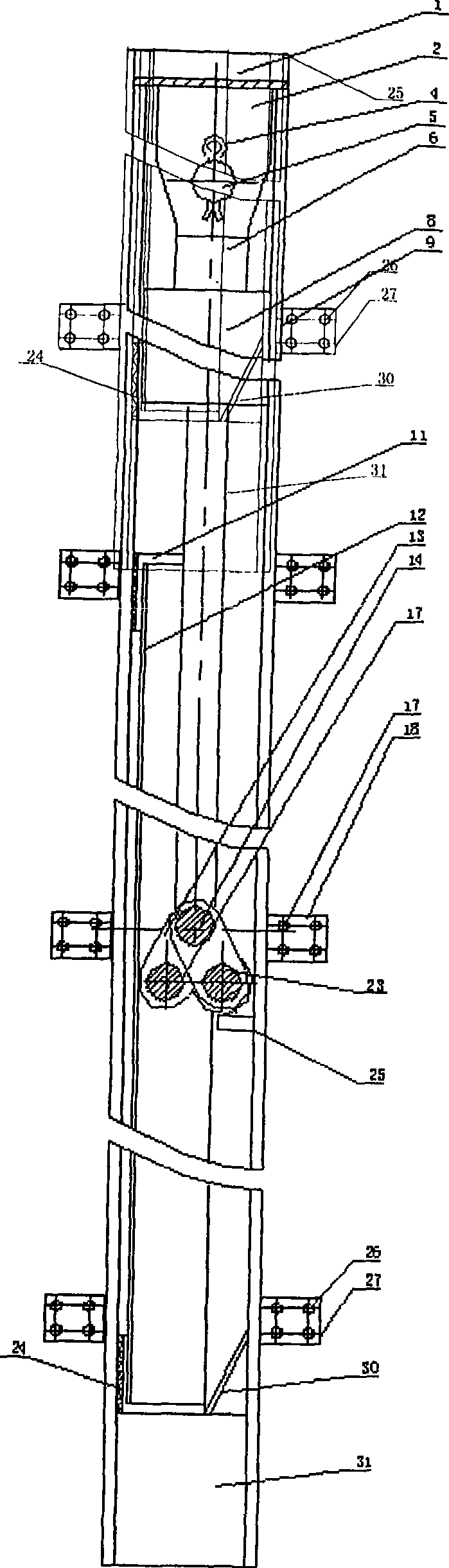

[0022] Such as figure 1 As shown, the present invention is made up of door panel member, door frame member, lifting opening and closing mechanism, positioning and guiding mechanism. in:

[0023] Door panel component: including the door 11 and the door panel 12, which are integrated by welding; the main function is to close the passage.

[0024] Door frame component: including the upper door frame 1, the left and right door frames 9 and the door lintel 10 that constitute the door panel 12 running limit channel; the upper door frame 1 is welded with the lifting lug connecting plate 2, and the left and right door frames 9 are welded with fixed ears 27; the upper door frame 1 Connect with the left and right door frames 9 through the door column connecting plate 28 and bolts 29; there are grooves on the sealing surfaces of the upper door frame 1, the left and right door frames 9 and the door lintel 10, and the sealing strip 24 is bonded in the groove to play the role of sealing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com