Balanced pressure flap gate

A flap valve and balance technology, which is applied in the field of flap valves, can solve problems such as impossibility of sealing and uncontrollable support balance, and achieve the effect of promoting detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

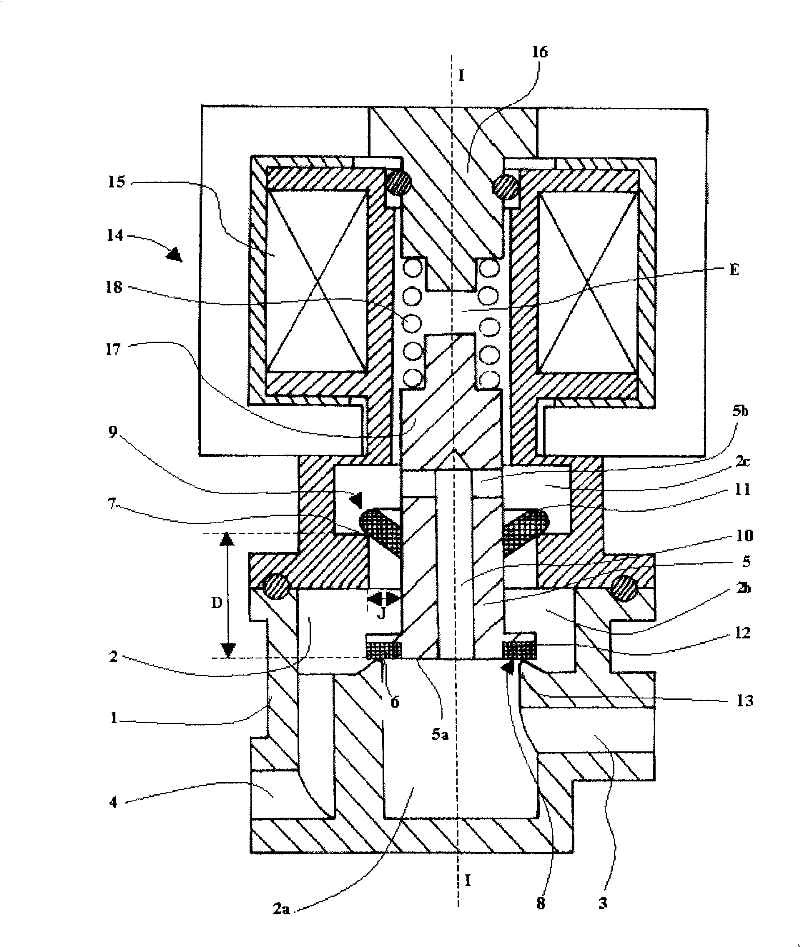

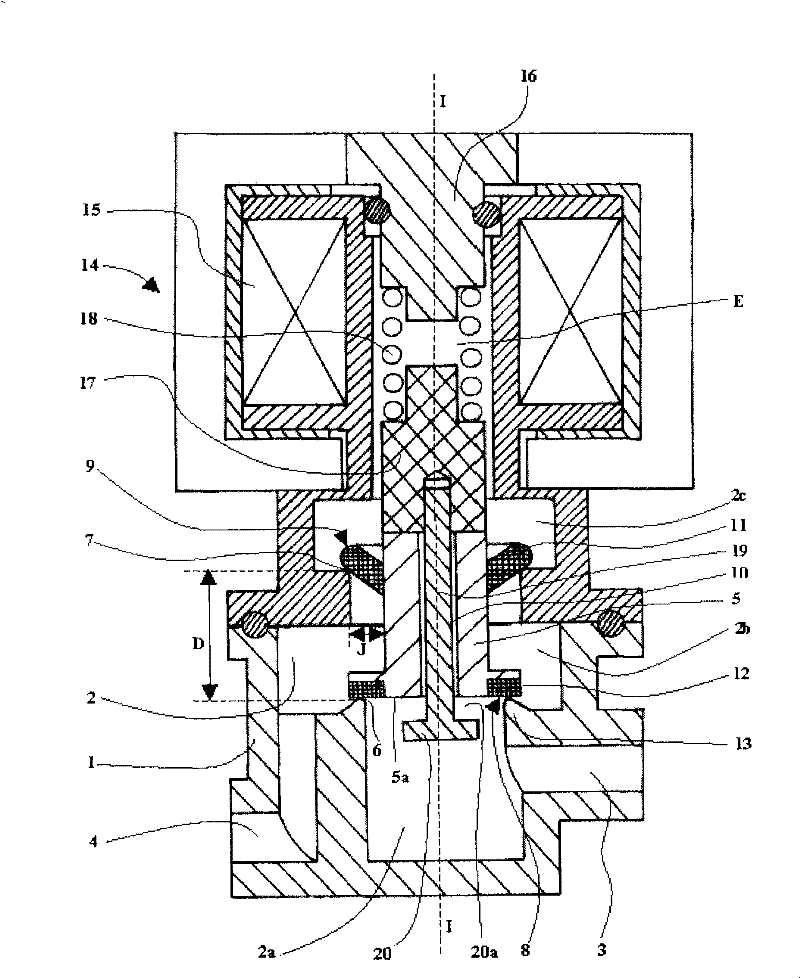

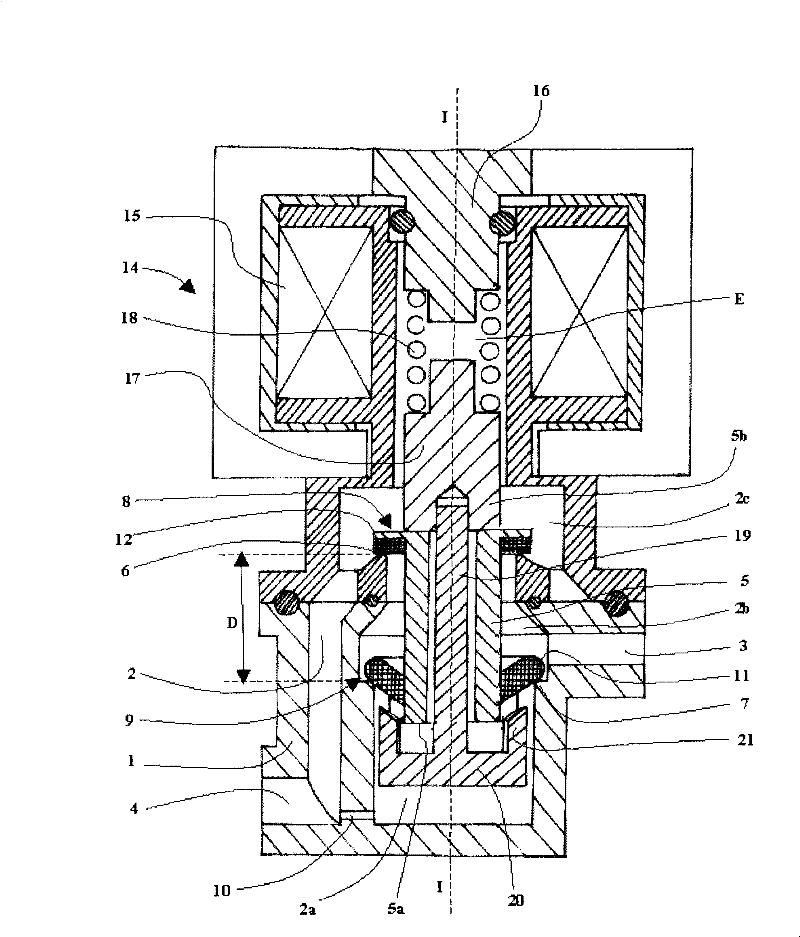

[0070] First consider as figure 1 The first embodiment shown, the described device can be found in all the embodiments shown in the other figures.

[0071] The flap valve according to the invention comprises a hollow valve body 1, eg made of metal or plastic material, having an inner chamber 2 which communicates with the outside by means of fluid inflow channels 3 and fluid outflow channels 4 separated from each other.

[0072] The movable throttle valve 5 is located in the inner chamber 2 of the valve body 1 and can slide along the moving direction I-I.

[0073] In the inner chamber 2 , the valve body 1 includes a first annular blocking seat 6 and a second annular blocking seat 7 . The first annular blocking seat 6 is an annular contact portion 13, eg figure 1 The middle-to-upper annular rib, and the second annular blocking seat 7 is formed by the shoulder edge of the inner chamber 2, which is in the figure 1 Increases from the middle to the upper part. The two annular bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com