Multi-arm machine that can form double-weaving mouth

A technology for dobby machines and textile machines, applied in the field of dobby machines, can solve the problems of fabric style limitation and formation of a single weaving fell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

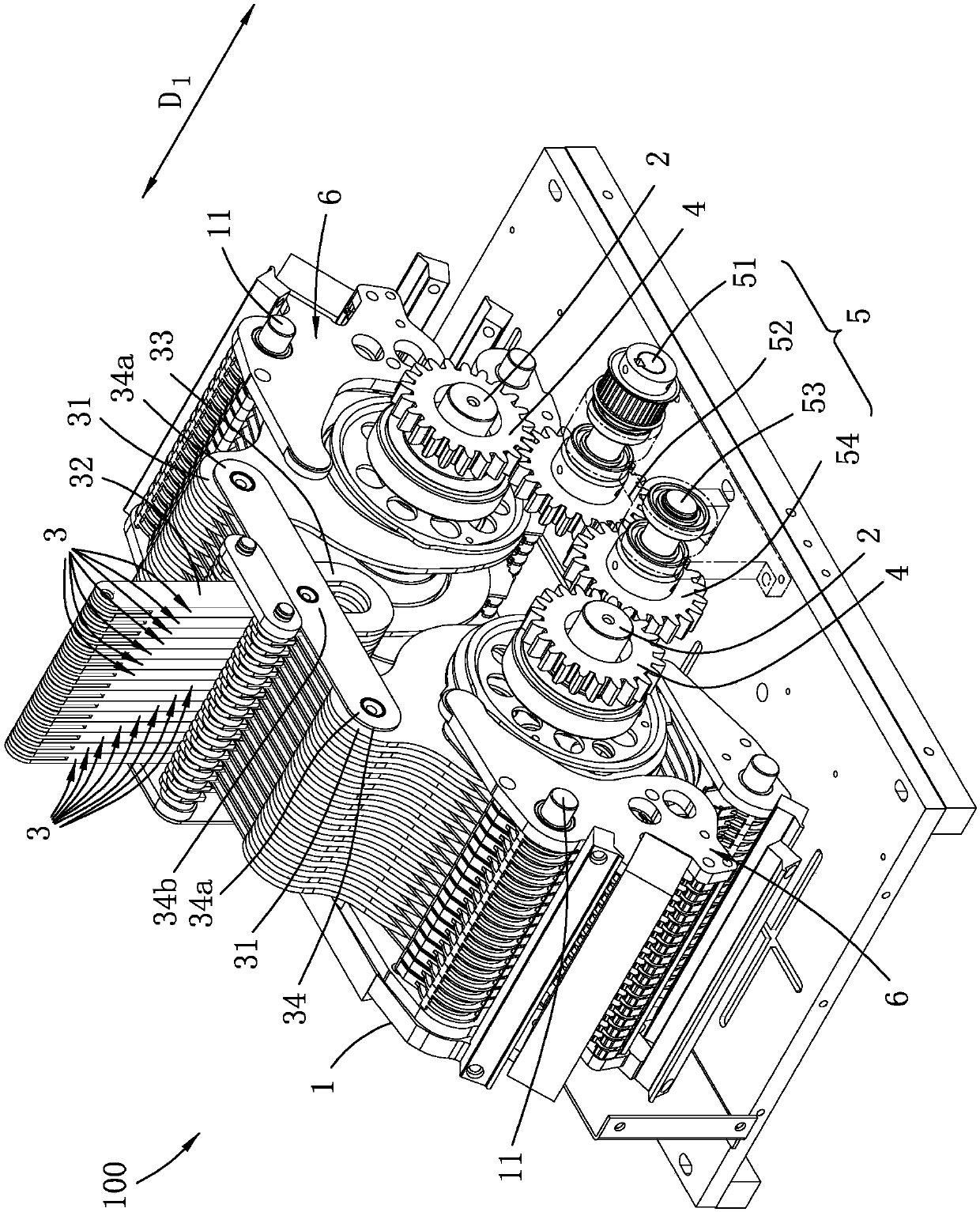

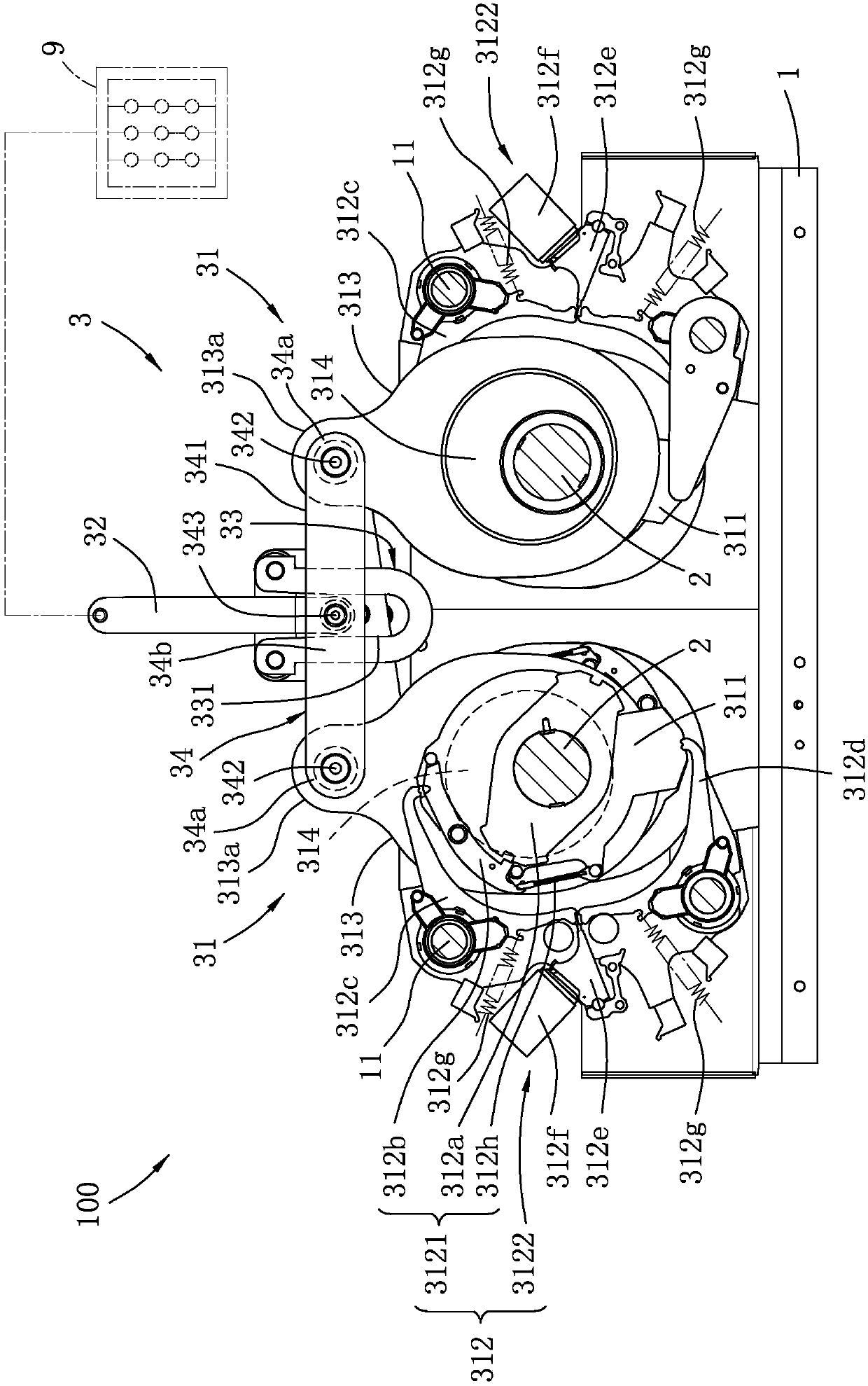

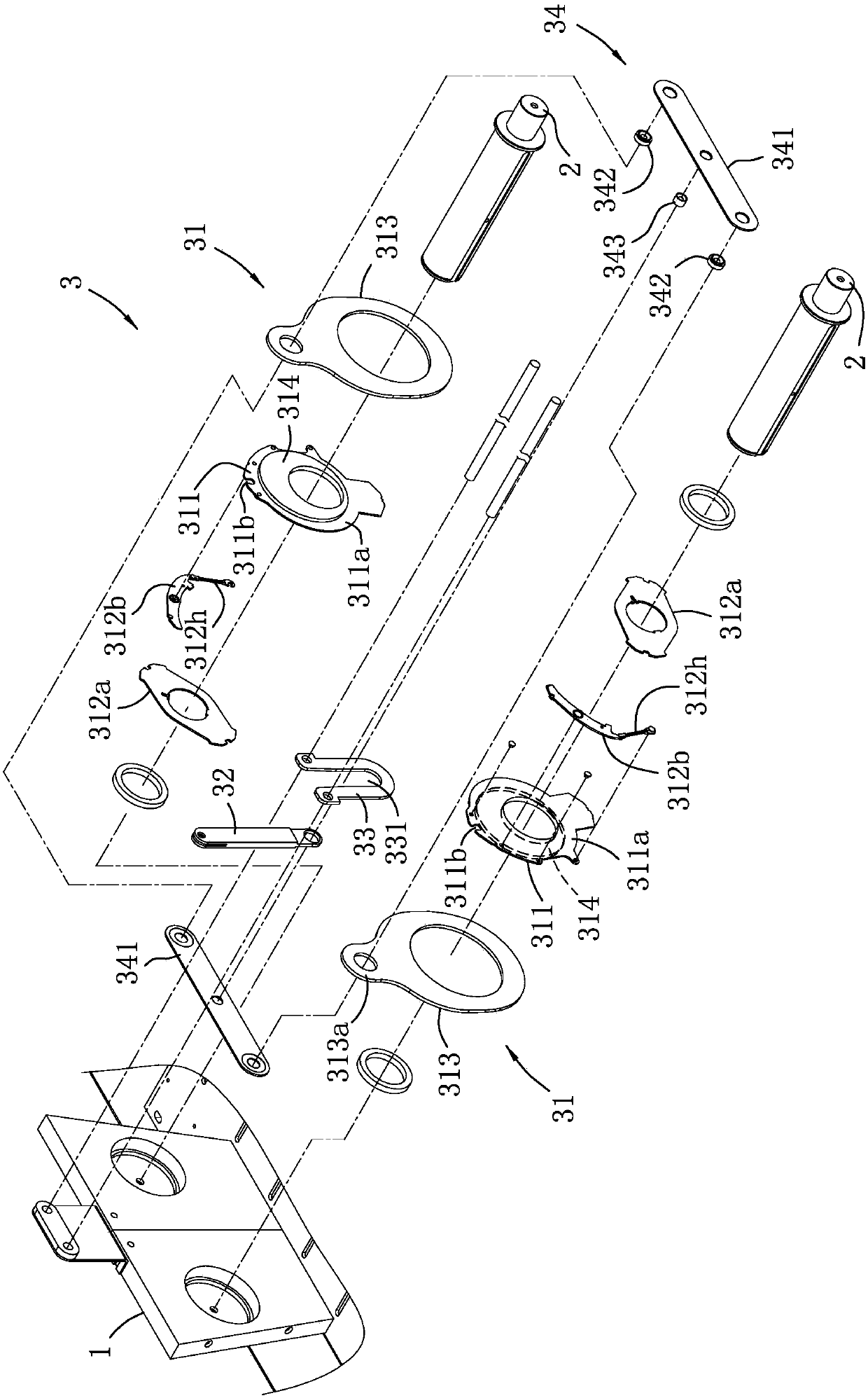

[0029] refer to figure 1 and figure 2 , a dobby 100 capable of forming a double loom in the present invention is suitable for connecting multiple heald frame mechanisms (not shown) of a textile machine (not shown), each heald frame mechanism includes a heald frame 9 . This embodiment includes a machine base 1 with two supporting rods 11, two rotating shafts 2 pivotally mounted on the machine base 1 at intervals and extending along a first direction D1, and a plurality of shafts arranged side by side in the first direction D1. The provided transmission assembly 3, two gears 4 respectively fixedly sleeved on the rotating shaft 2, a power input module 5 provided on the machine base 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com