Assembling structure for flow passage board and following layer of fuel battery

A technology of assembling structure and fuel cell, which is applied in the parts of fuel cell, fuel cell, battery electrode, etc., and can solve the problems affecting the power generation effect of fuel cell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

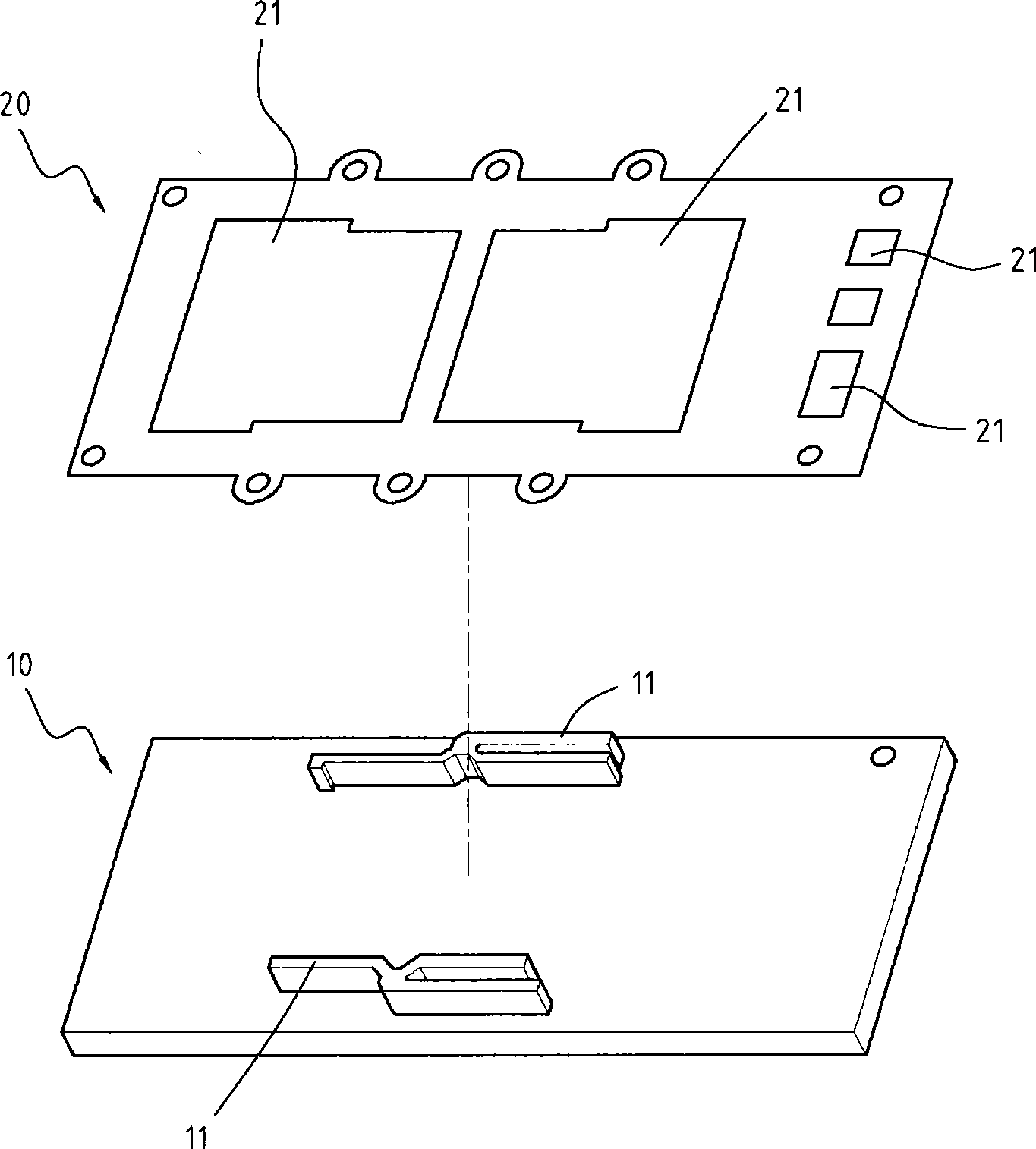

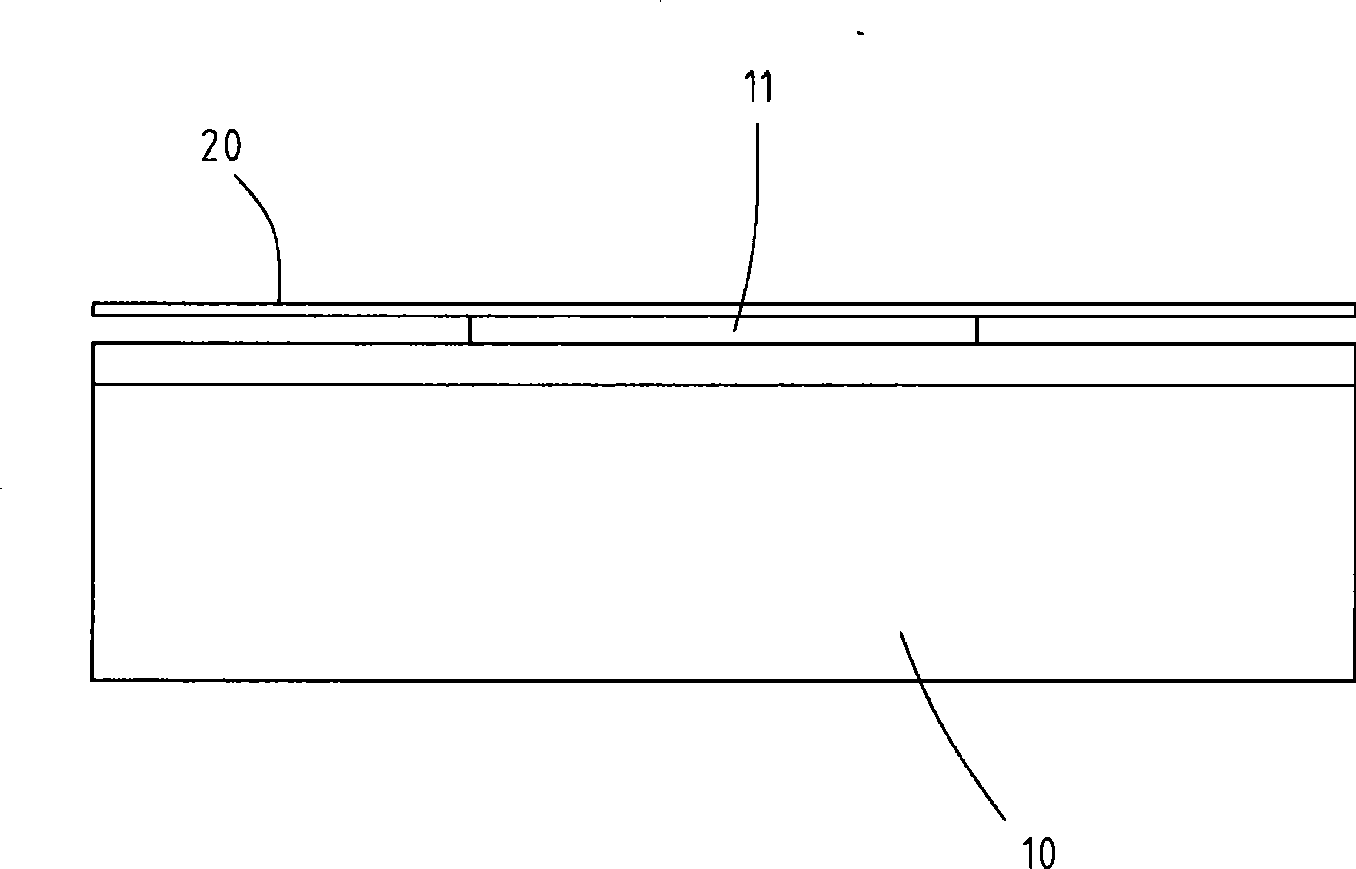

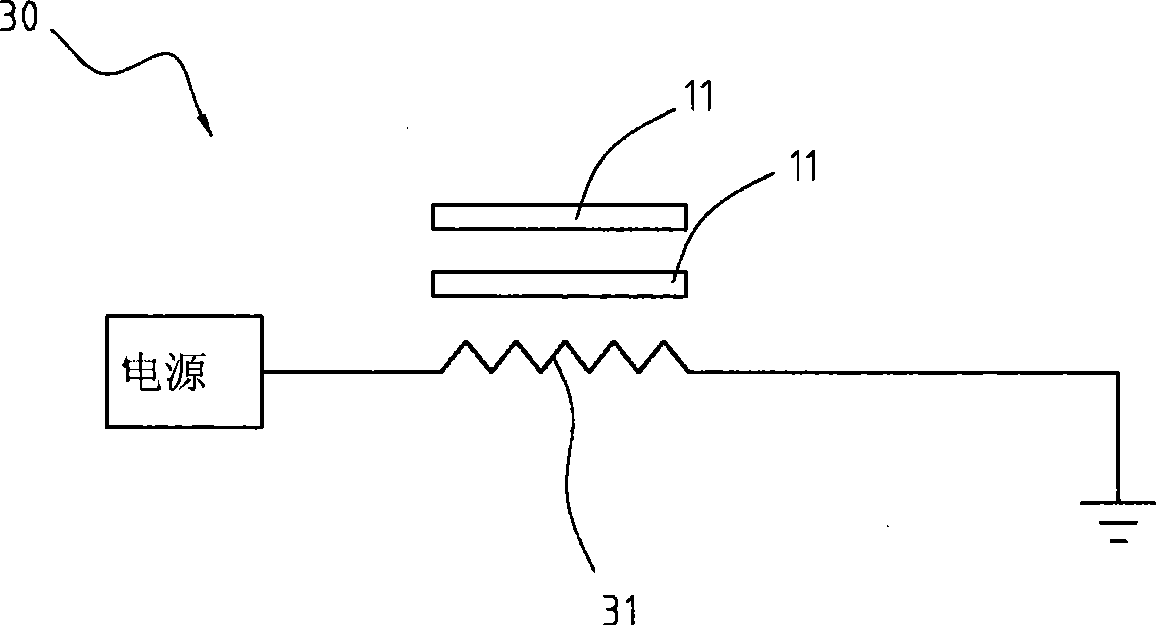

[0021] figure 1 A three-dimensional exploded view showing that the adhesive layer of the present invention is placed on the heater, figure 2 A plan combination diagram showing the placement of the adhesive layer on the heater according to the present invention, image 3 A schematic diagram showing the heating circuit of the heater of the present invention, Figure 4 An exploded perspective view showing the pre-hardened regions of the adhesive layer of the present invention placed on the runner plate after hardening. The assembly structure of the flow channel plate and the bonding layer for the fuel cell of the present invention is applied in the fuel cell, which includes: the bonding layer 20 and the flow channel plate 40 . The flow channel plate 40 includes a plate body 41 and a plurality of flow channels, which are disposed on the surface of the plate body 41 and recessed from the surface 41 , and these components will be described in detail below.

[0022] The next laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com