Rotor of synchronous reluctance motor

一种同步磁阻、电动机的技术,应用在制造电动发电机、电动组件、磁路转动零部件等方向,能够解决结合力减小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0034] The rotor of the synchronous reluctance motor according to the present invention will be explained in more detail with reference to the accompanying drawings.

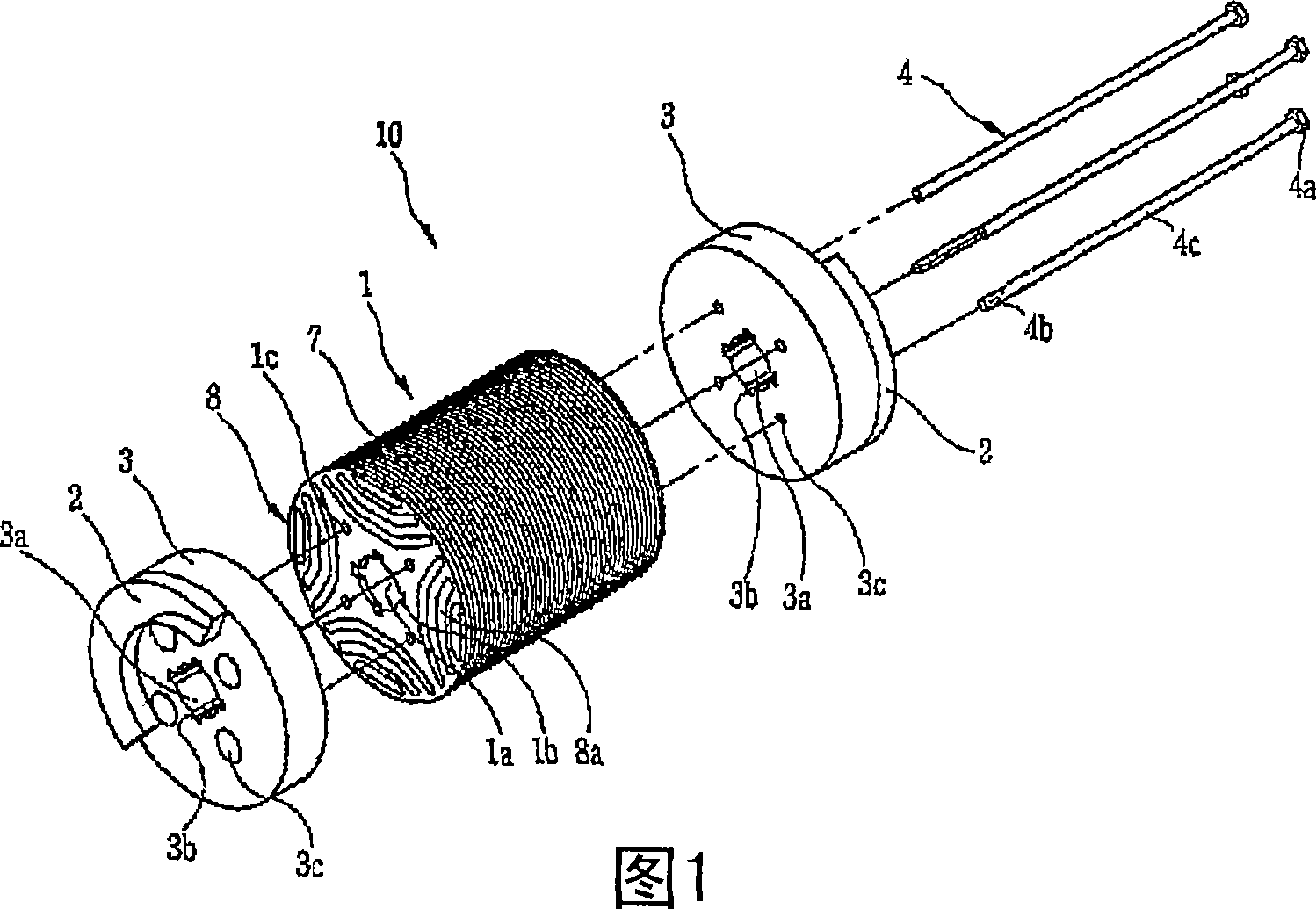

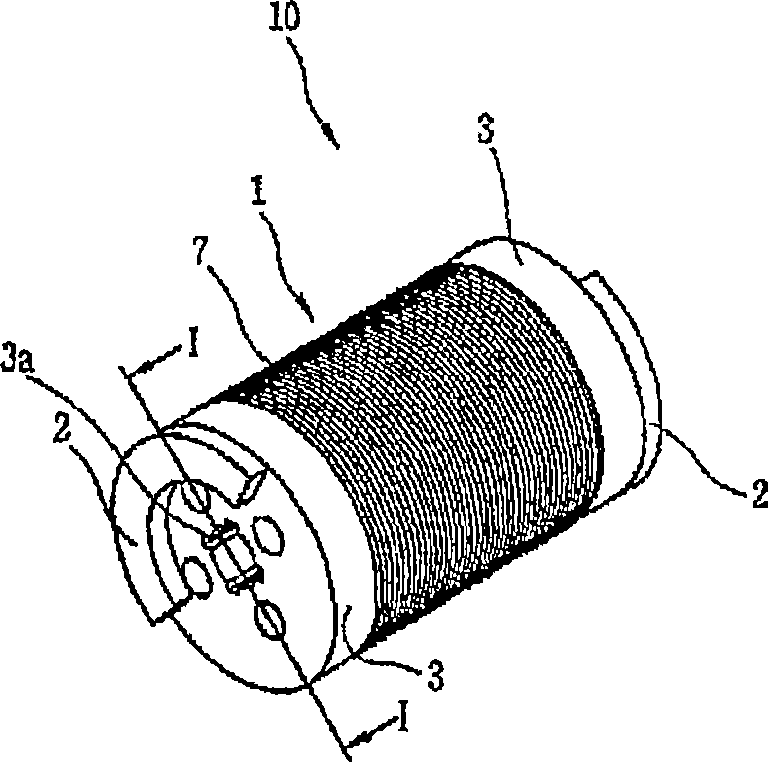

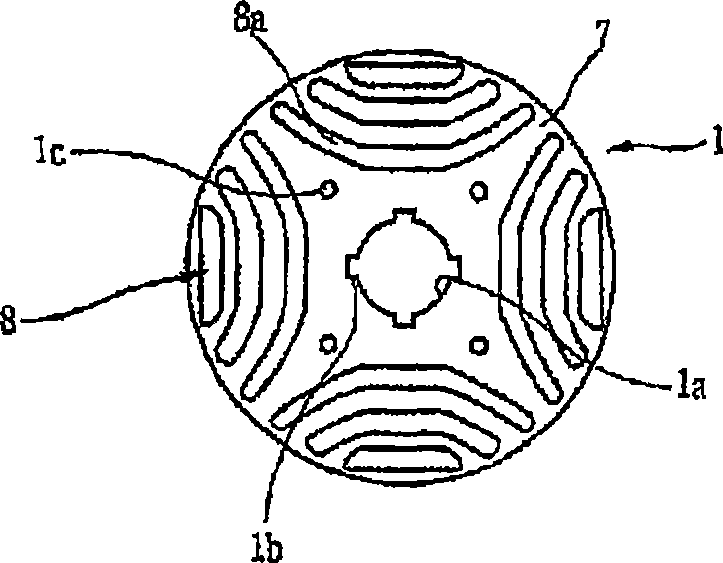

[0035] Figure 5 is an exploded perspective view showing a rotor of a synchronous reluctance motor according to the present invention, Figure 6 is an assembled perspective view showing a rotor of a synchronous reluctance motor according to the present invention, Figure 7 is a plan view showing the laminated iron core in the rotor of the synchronous reluctance motor according to the present invention, and Figure 8 is along Figure 7 Sectional view of line II-II cut.

[0036] As shown, the rotor 100 of the synchronous reluctance motor according to the present invention includes a laminated iron core 110 formed to laminate a plurality of silicon steel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com