Method for repairing diesel engine cylinder Glan hole defect

A repair method and diesel engine technology, applied in the field of diesel engines, can solve problems such as unreachable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

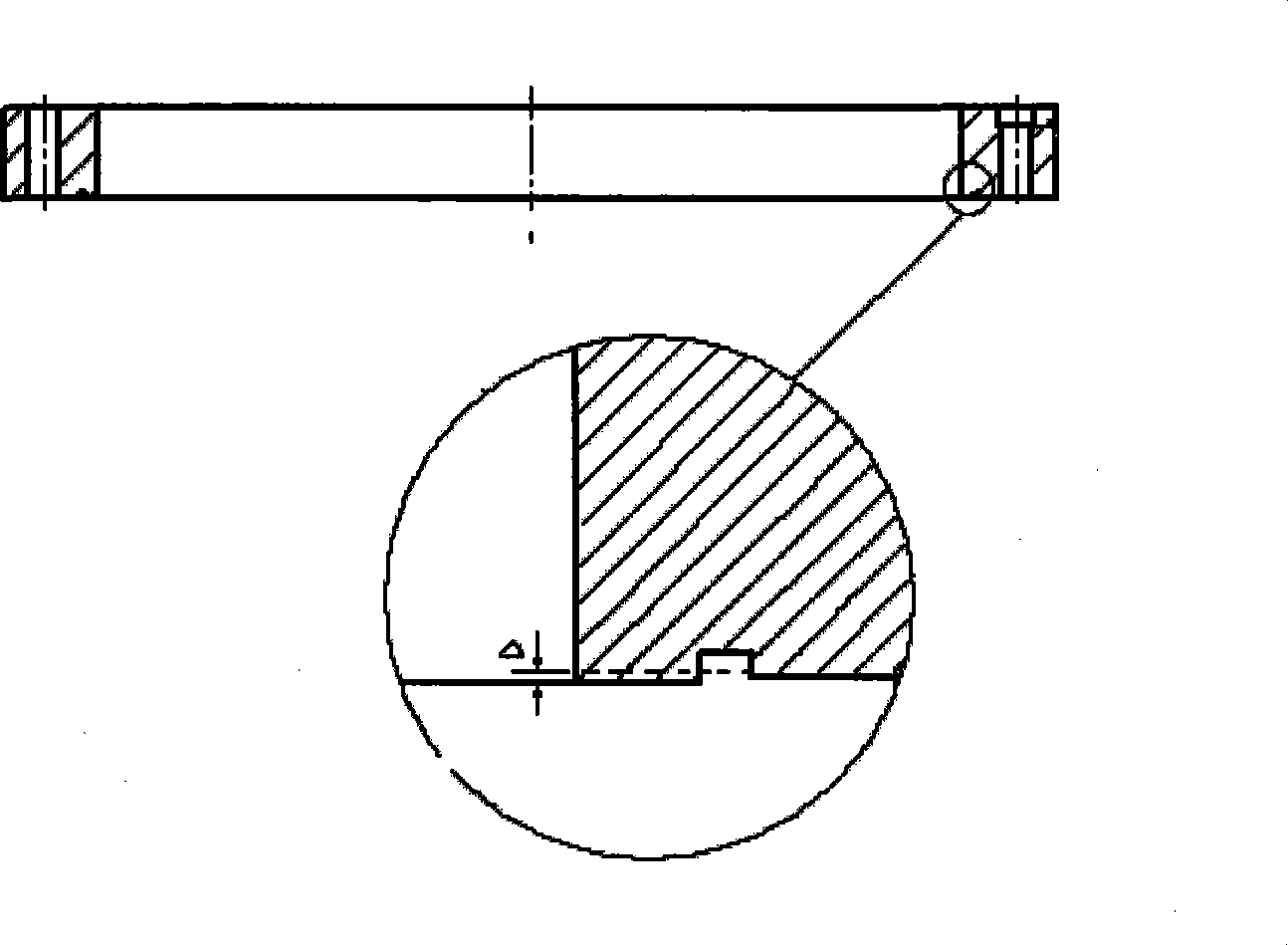

[0028] A method for repairing granholes of a diesel engine cylinder block according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but this should not limit the protection scope of the present invention.

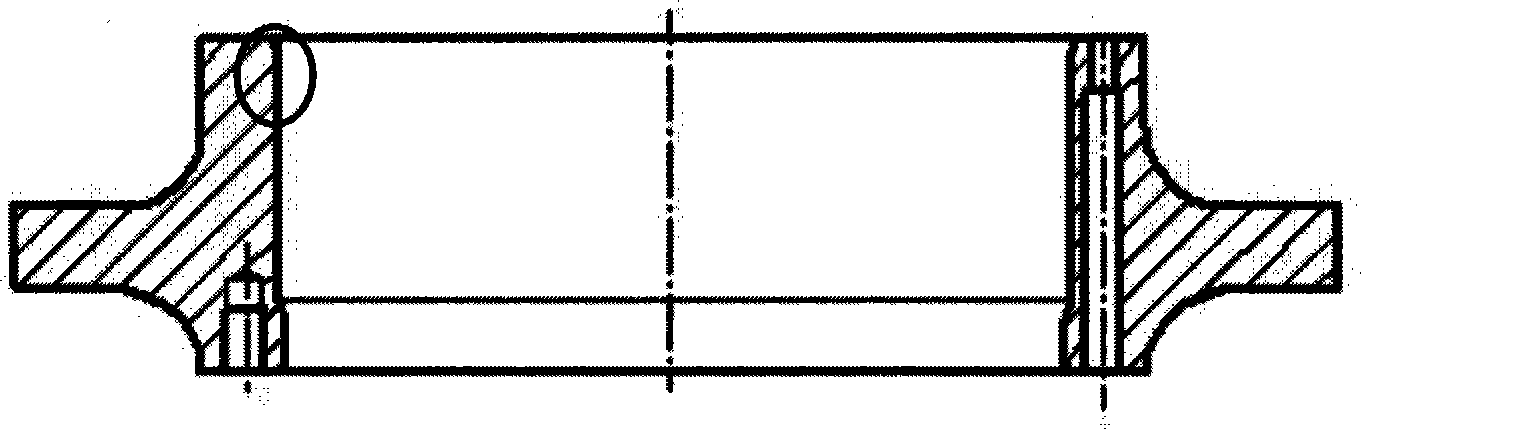

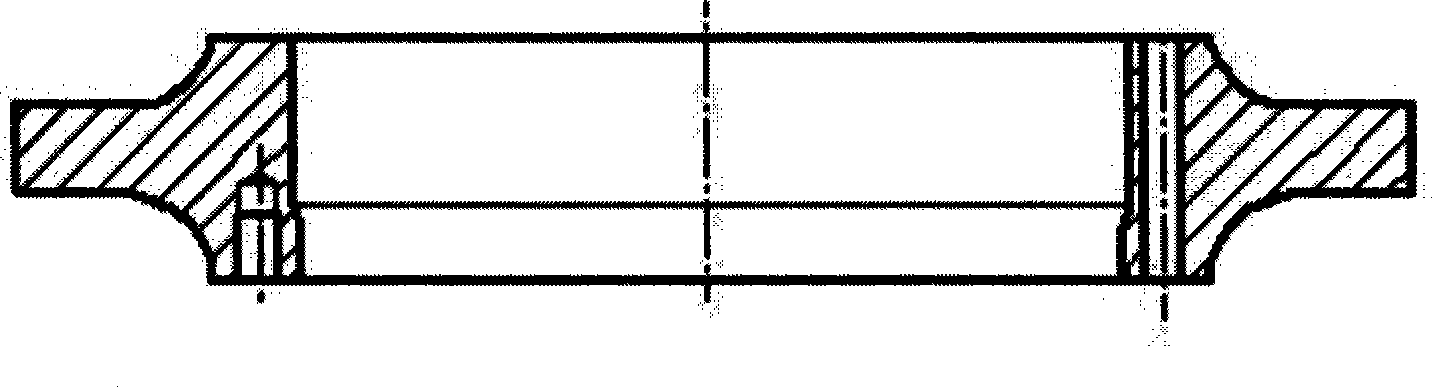

[0029] The gland hole of the cylinder body is located on the lower plane of the cylinder body, and the piston rod-stuffing box assembly will be installed, and the stuffing box lubricating oil will flow in the oil chamber formed between the gland hole and the stuffing box. Since the cylinder block is a large casting, the gland hole is located on the riser surface. After the cylinder block is cast, it is easy to have casting defects at the position of the gland hole, and processing defects such as stem knives may also be caused by mistakes during processing. If there is a defect and it is not repaired, it will fail to meet the design requirements due to oil leakage, and cause the entire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com