A movable switching station of a magnetic suspended railway system

A switch station and maglev train technology, which is applied in railway vehicles, motor vehicles, electric vehicles, etc., can solve the problems of the switch station occupying more space and weight, and achieve the effects of weight reduction, compact structure and good maintainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

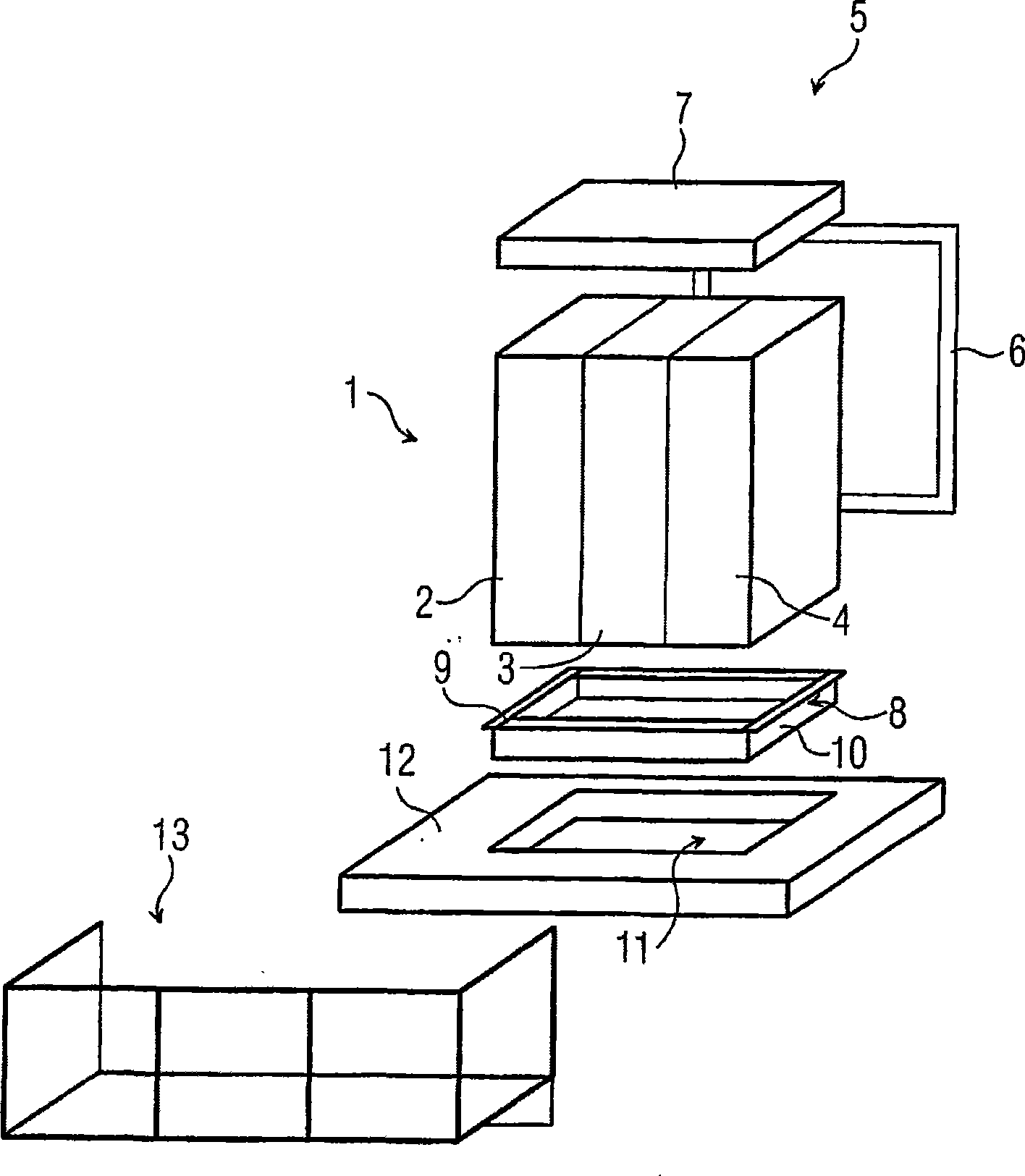

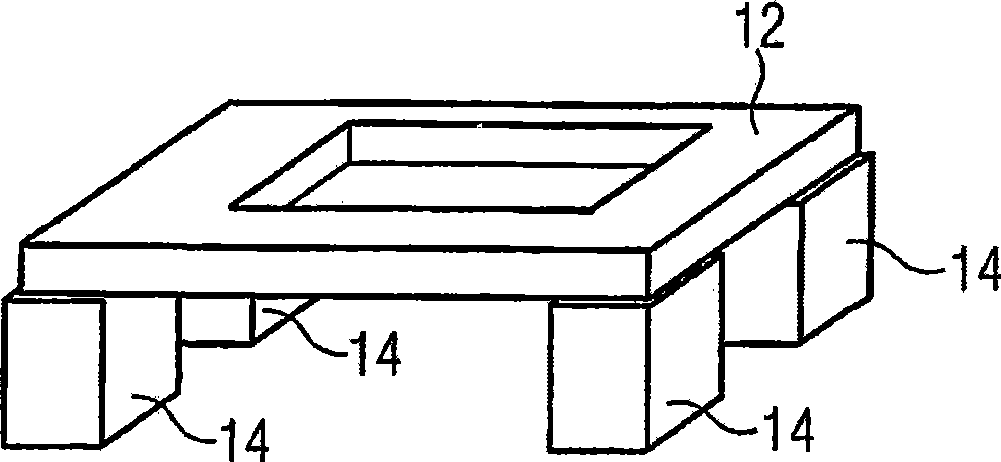

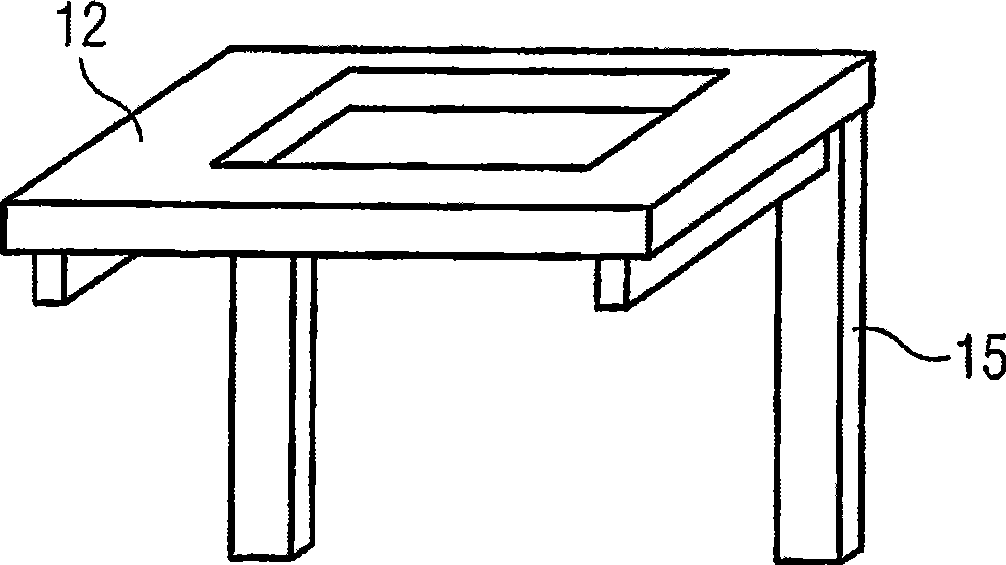

[0019] figure 1 An exemplary embodiment of a switchyard 1 of an arrangement according to the invention is shown, here the switchyard 1 comprises a cable entry plate 2 , a stator supply plate 3 and a stator star component plate 4 . The device is used to connect and disconnect the stator segments not shown in the figure from the power supply. The stator segments and power supply are integral parts of the maglev railway system. The shells of the three distribution boards 2 , 3 , 4 are connected to each other by a fixing device 5 , wherein the fixing device 5 includes a cabinet clamping device 6 and a top cover 7 and a base 8 . The cabinet clamping device 6 is detachably screwed to the housing of the switchboard 2, 3, 4 by suitable screw connection means. Putting on the top cover 7 which is designed to fit exactly with the upper area of the switchboard shell, the switchboards 2, 3, 4 are more stable in the upper area. The base 8 has a peripherally closed annular flange portio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap