An active yarn guide with a movable yarn feeding ring

A braking device and yarn feeding technology, applied in textiles and papermaking, weft knitting, knitting and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

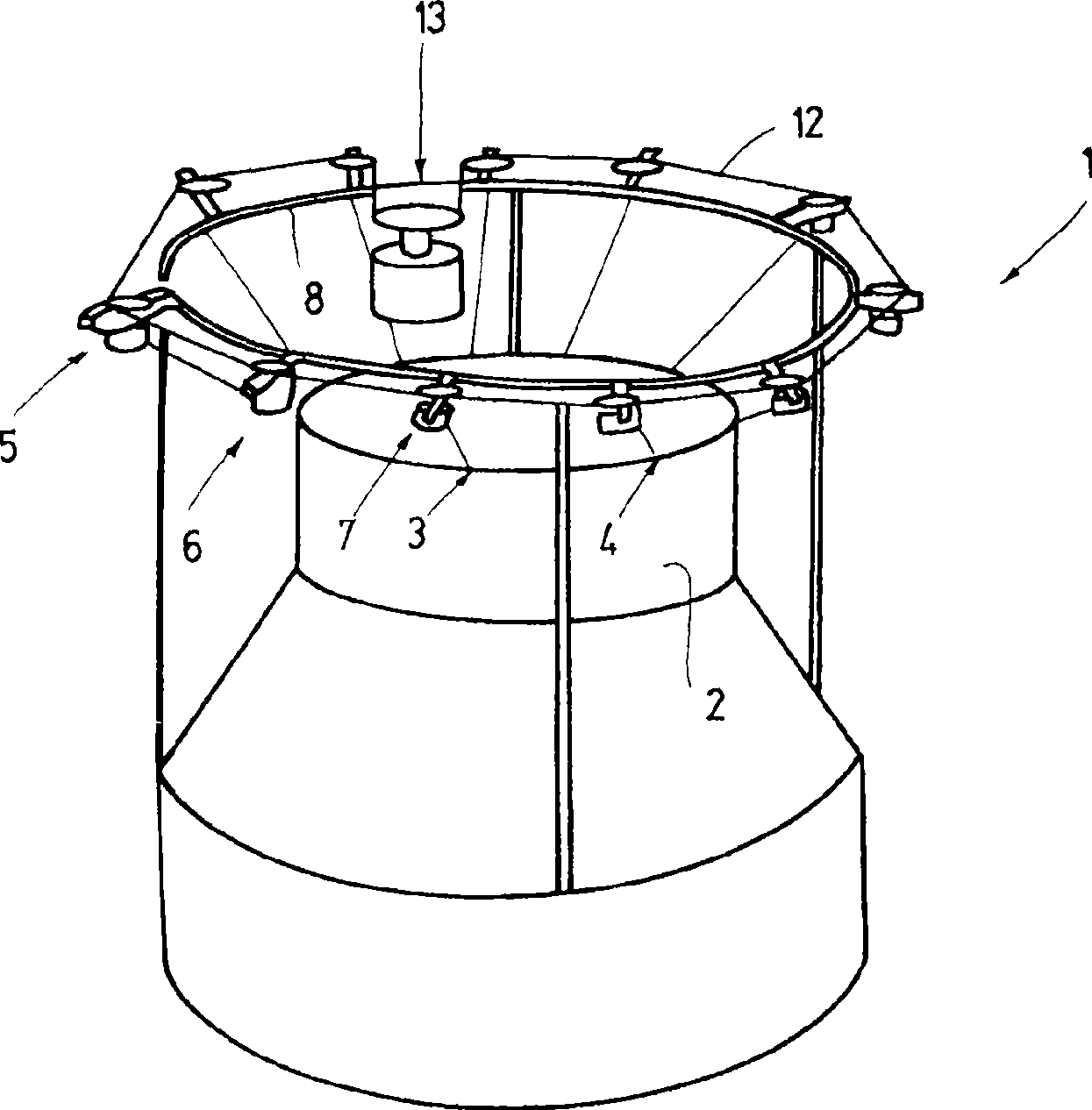

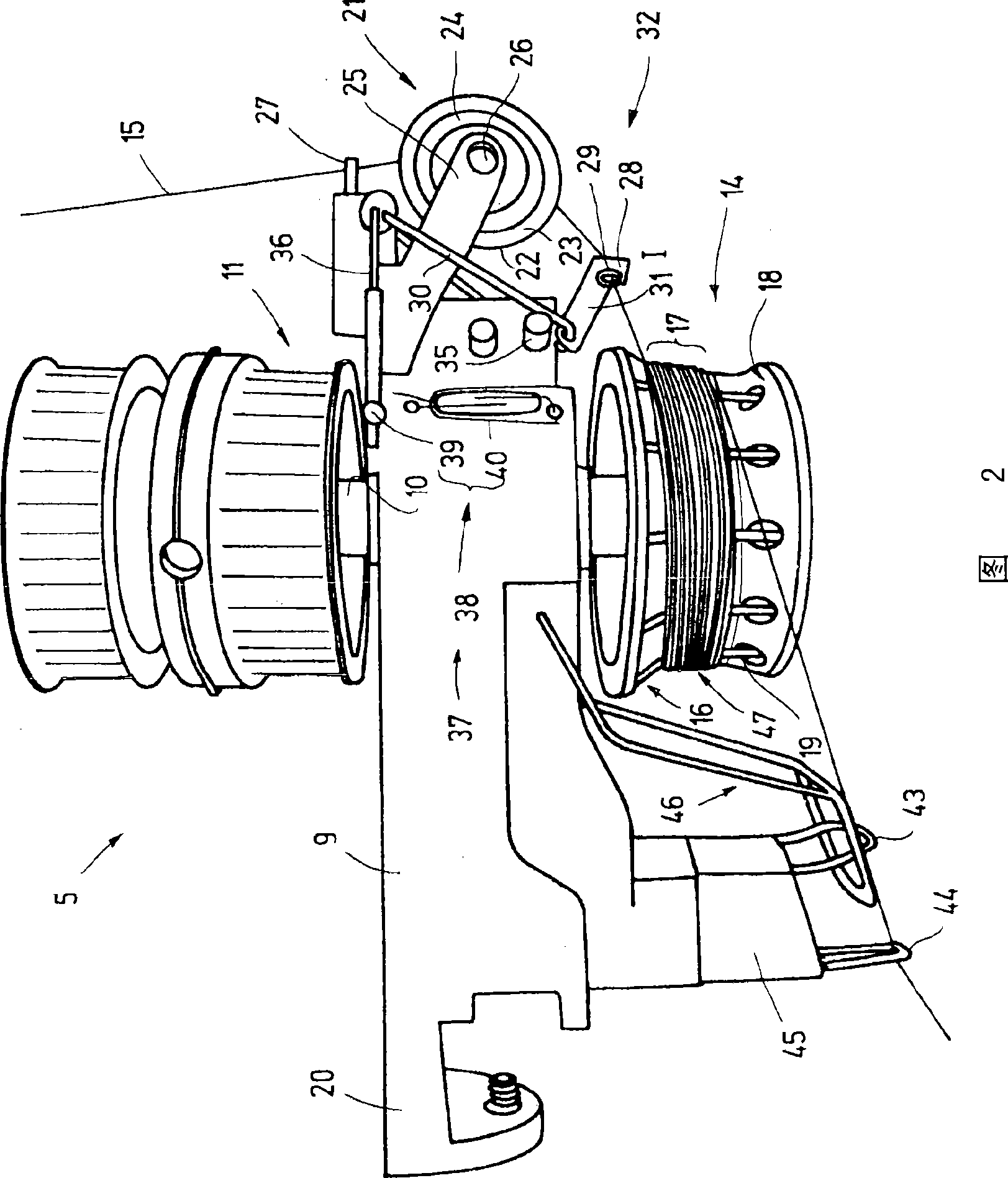

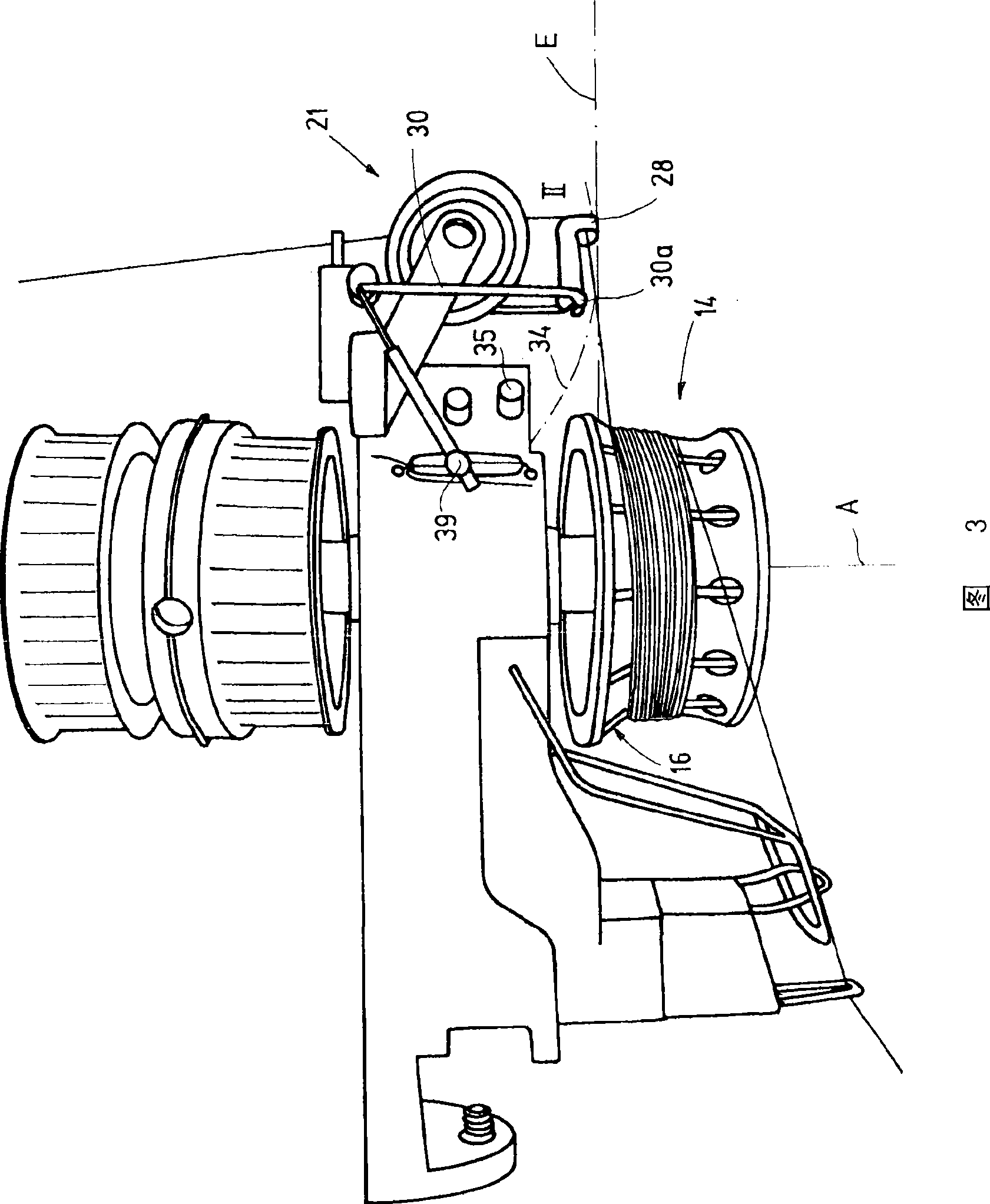

[0028] figure 1 A circular knitting machine 1 is shown, which includes a knitting cylinder 2 with a large number of knitting needles not shown further. The knitting needles form knitting positions 3, 4 (and others), and the yarn is guided to these knitting positions. For this purpose, yarn feeders 5, 6, 7, etc. are used, which are arranged on the machine ring 8 held above the weaving drum 2 and extend from the machine ring 8 in the radial direction. The yarn feeders 5, 6, 7 and the like are preferably configured the same as each other. FIG. 2 shows an example configuration with the aid of the yarn feeder 5. Each of these feeders has a support 9 made of metal or, for example, plastic. In use, a shaft 10 (see FIGS. 2 and 3) oriented substantially vertically is rotatably supported on the bracket 9. The upper end of the shaft 10 supports at least one pulley 11, figure 1 The toothed belt 12 shown schematically in FIG. 1 travels through the pulley 11 and causes all or at least part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com