Active yarn guide with a movable yarn feeding ring

A technology of yarn feeding ring and brake device, which is applied in textiles and papermaking, weft knitting, knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

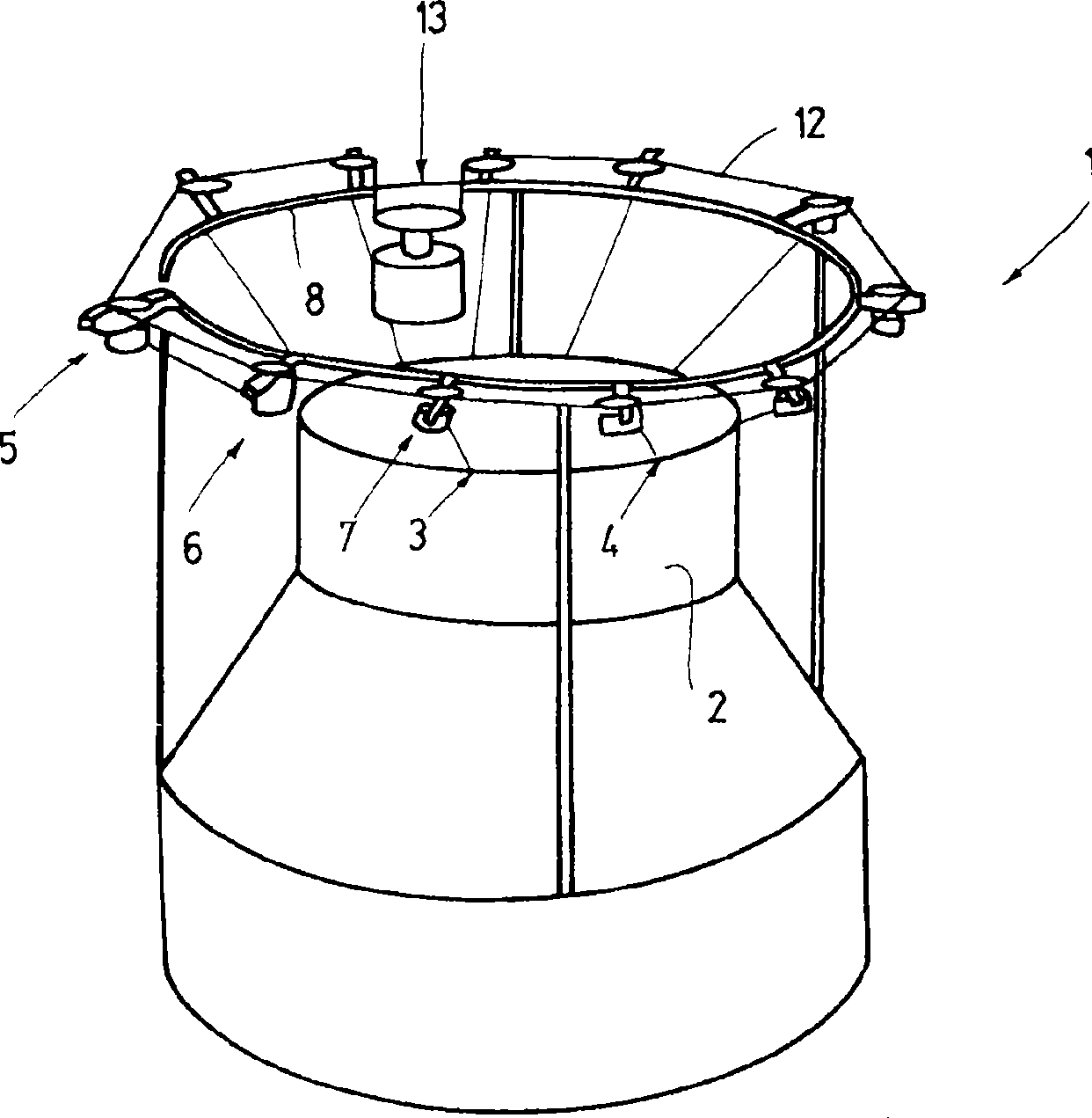

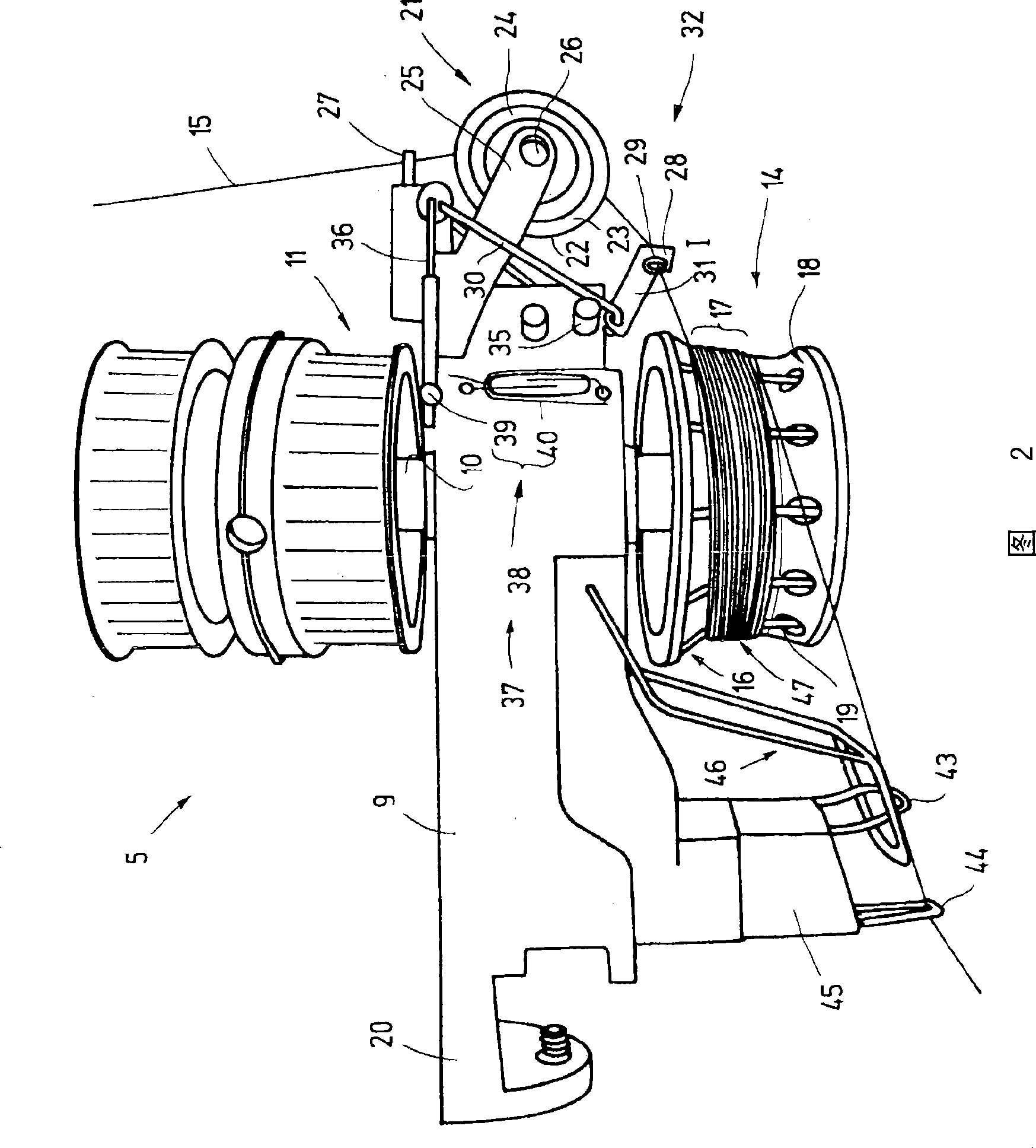

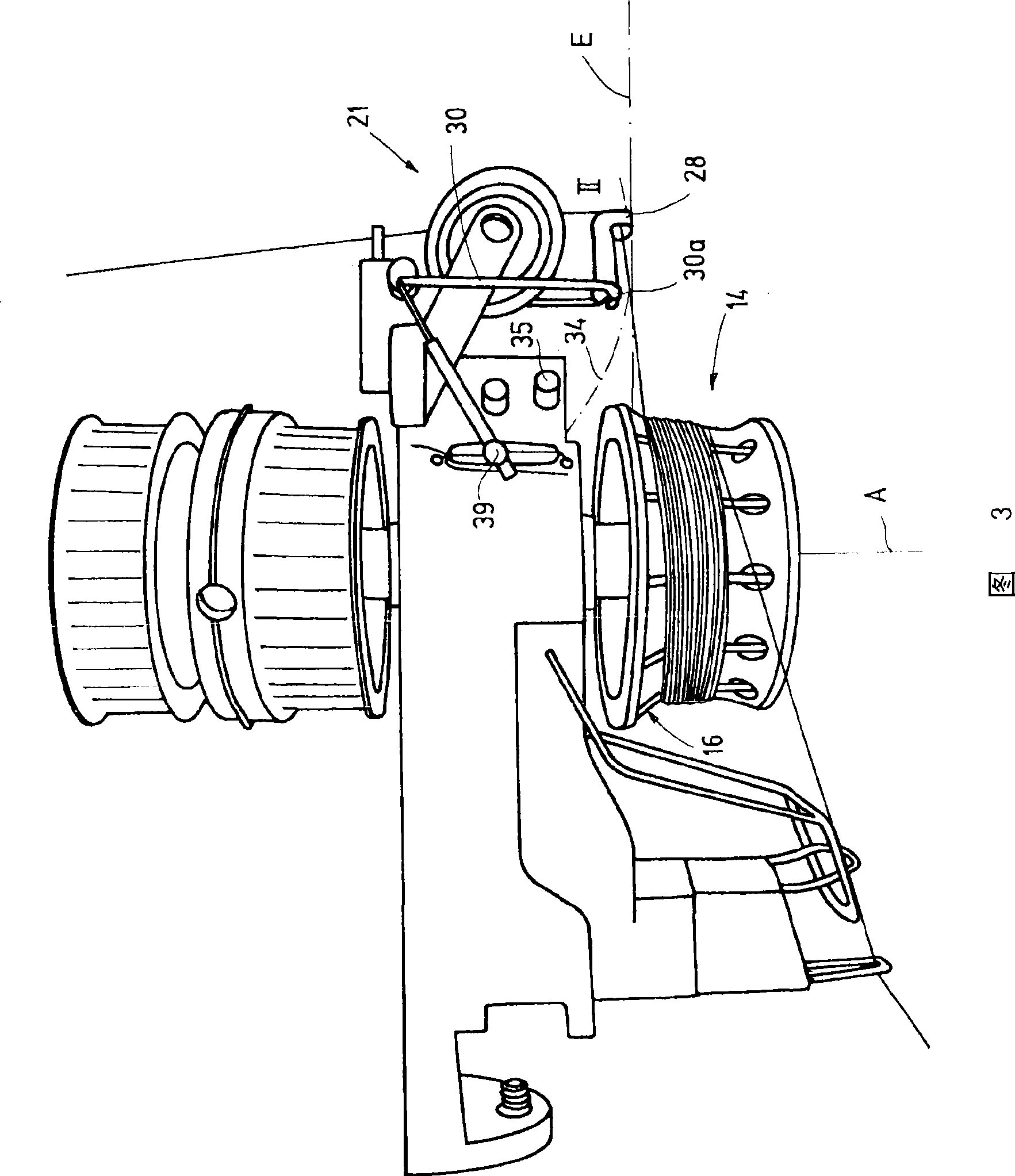

[0028] figure 1 A circular knitting machine 1 is shown in , which comprises a knitting cylinder 2 with a large number of knitting needles not further shown. The knitting needles form the knitting positions 3, 4 (and others) to which the yarn is guided. For this purpose yarn feeders 5 , 6 , 7 etc. are used, which are arranged on a machine ring 8 held above the weaving cylinder 2 and extend radially from the machine ring 8 . The yarn feeders 5, 6, 7 etc. are preferably configured identically to one another. figure 2 An exemplary configuration is shown by means of the yarn feeder 5 . Each of these yarn feeders has a support 9 made of metal or, for example, plastic. Shaft 10 oriented substantially vertically in use (see figure 2 and 3 ) is rotatably supported on the bracket 9. The upper end of shaft 10 supports at least one pulley 11, in figure 1 A toothed belt 12, shown schematically in , travels through the pulley 11 and causes all or at least a part of the yarn feeders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com