Window sliding support component

A sliding brace and component technology, applied in the direction of building fasteners, wing sash fasteners, buildings, etc., can solve problems such as damage to positioning blocks or guide rails, wind breaking window glass, inconvenient use, etc., to achieve locking The effect of stability, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

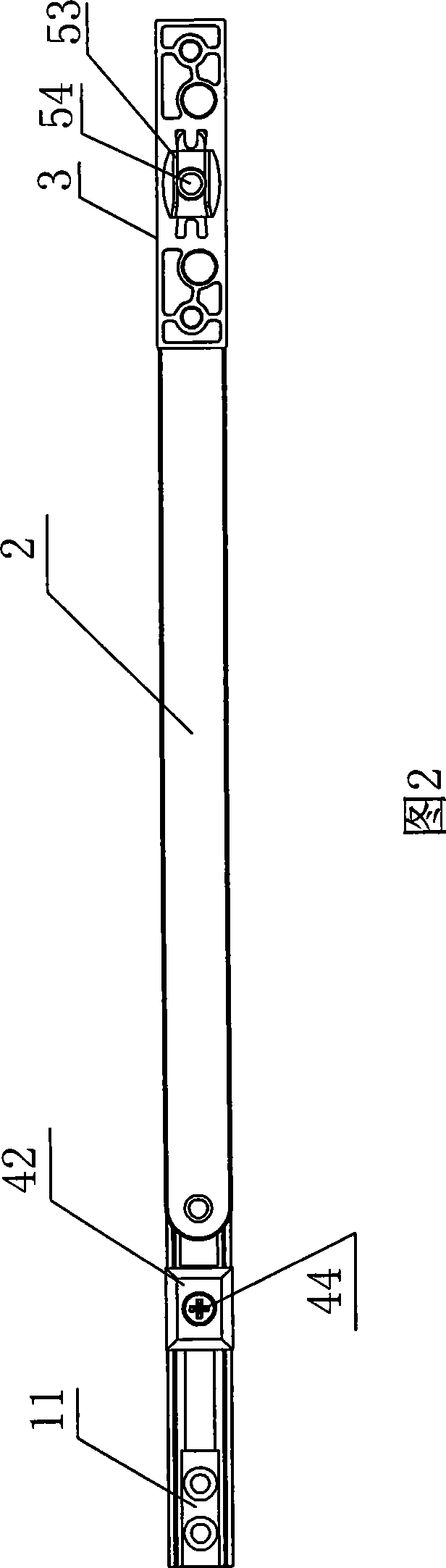

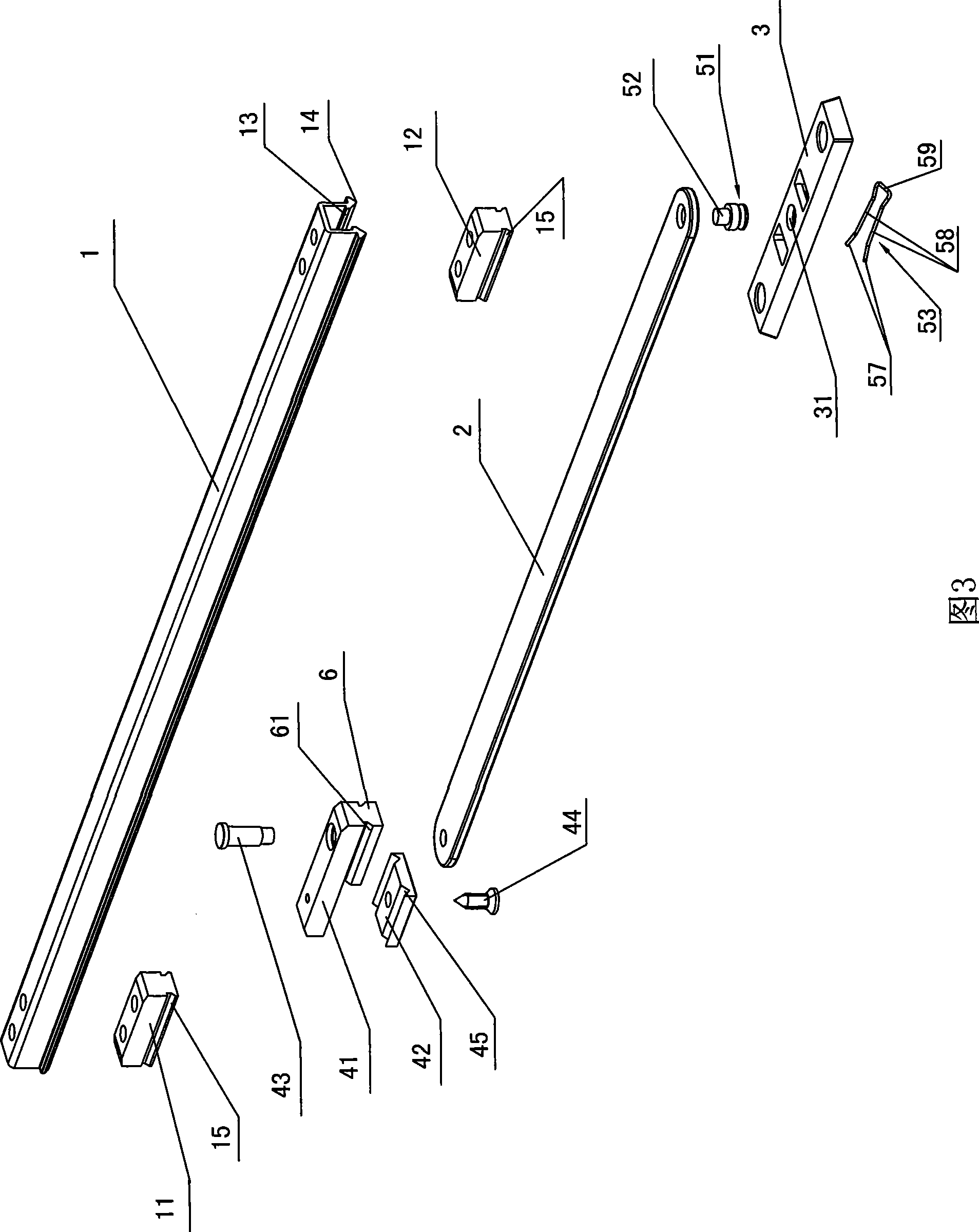

[0023] Embodiment 1: As shown in Figure 1, Figure 2 and Figure 3, a window sliding stay assembly includes a guide rail 1, a connecting rod 2, a sliding mechanism and a positioning block 3, the sliding mechanism is connected to the guide rail 1, and the opening edge of the guide rail 1 A limit mechanism is provided, and the limit mechanism includes a first limit portion 13 extending inward and a second limit portion 14 extending downward. Both ends of the guide rail 1 are connected with a first boss 11 and a second boss 12. Both sides of the bottom of the first boss 11 and the second boss 12 are respectively provided with a first groove 15 that cooperates with the first limiting part 13, so that the first limiting boss 11 and the second boss 12 fit into the guide rail 1 Two ends, and it is fixed on the window frame by fixing piece, the setting of the first boss 11 and the second boss 12 have avoided slide mechanism sliding out of guide rail 1 two ends when sliding in guide rail ...

Embodiment 2

[0027] Embodiment 2: as shown in Fig. 4, Fig. 5 and Fig. 6, other structures are the same as Embodiment 1, the difference is that the lower end of the slider 41 is provided with a positioning cylinder 73 coaxially connected with the rivet post 43, and the first boss The lower end of 11 is provided with a positioning boss 71, and one side of the positioning boss 71 is provided with a positioning groove 72, and the positioning groove 72 is embedded and connected with the positioning cylinder 73. When using the present invention, when the window sash is opened to the limit position, the positioning cylinder 73 is just embedded In the positioning groove 72, the window sash is firmly locked on the window frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com