Eccentric spindle type vibrating feeder

An eccentric shaft and feeder technology, which is used in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of high transmission noise of the vibrator and uneven conveying of materials, and achieve large transmission vibration amplitude and compact device structure. , the effect of uniform transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

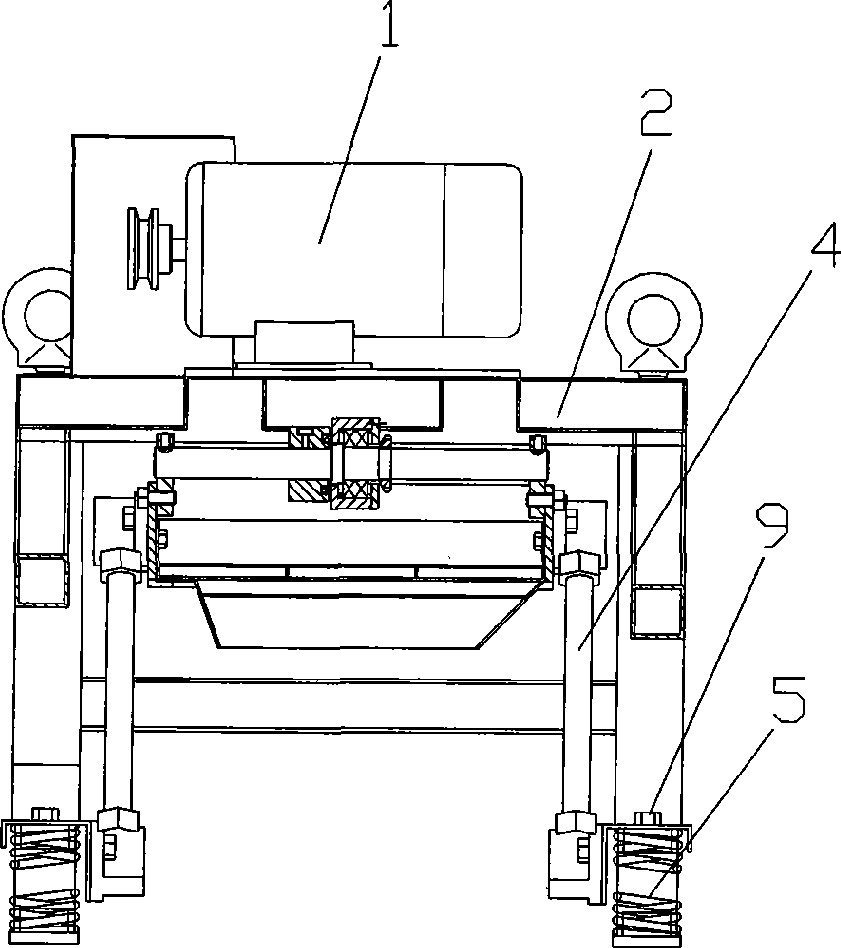

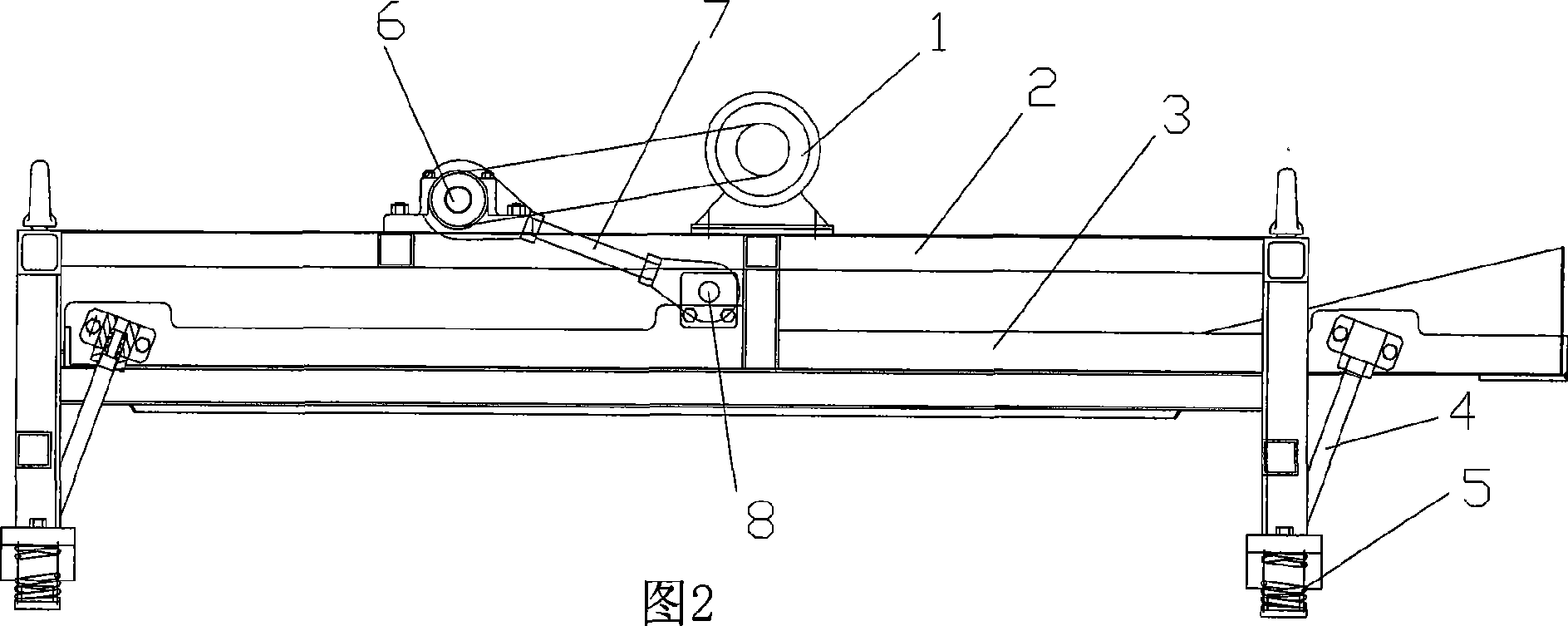

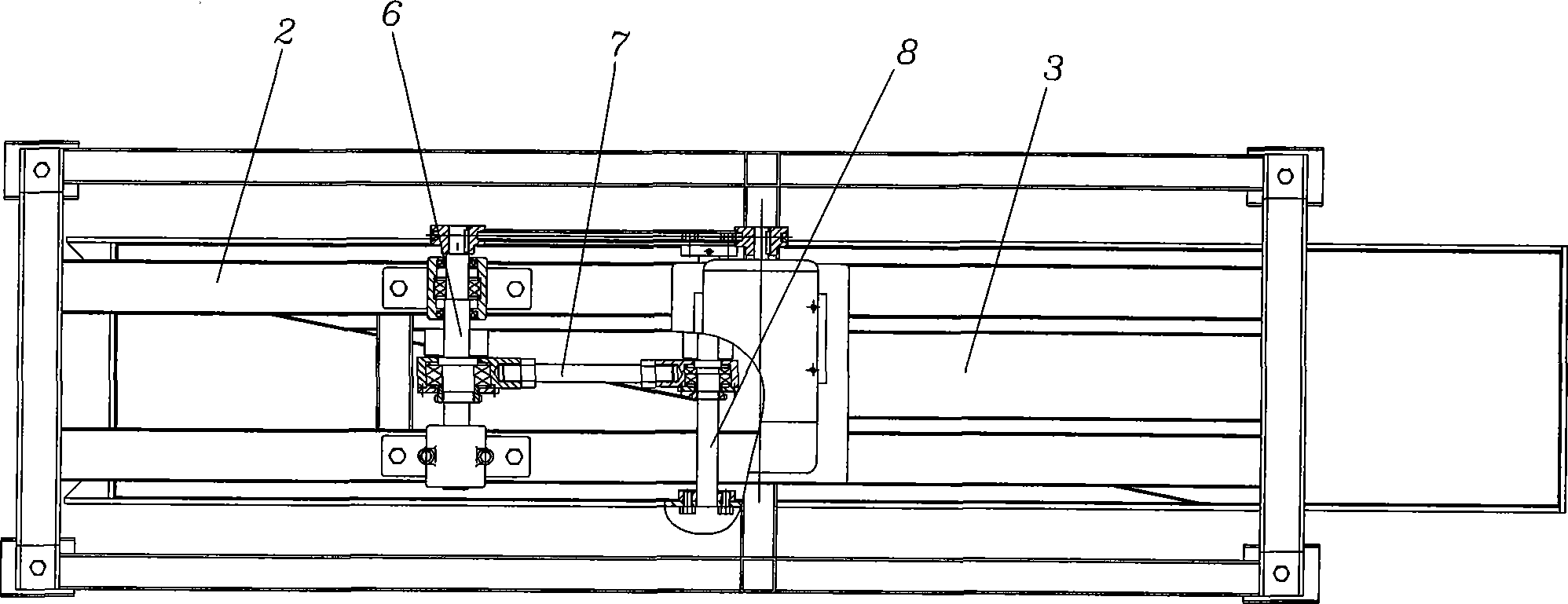

[0015] see figure 1 , Figure 2 and image 3 , located above the area to be detected, a DC motor 1 and an eccentric shaft 6 driven by the DC motor 1 are set on the bracket 2, flexible struts 4 are respectively set on the four legs of the bracket 2, and the feeding tray 3 is formed by four at the bottom The flexible struts 4 parallel to each other form a flexible support, and the feeding pan 3 is articulated on the upper part with a connecting rod 7, and the connecting rod 7 is driven by an eccentric shaft 6.

[0016] The corresponding structural settings in the specific implementation include:

[0017] A driven shaft 8 is set on the tray 3 , an eccentric shaft 6 is arranged on the support 2 , and one end of the connecting rod 7 is hinged on the driven shaft 8 , and the other end is hinged with the eccentric shaft 6 .

[0018] Compression springs 5 are respectively provided at the bottoms of the legs 9, and the impact of vibration on the sorting accuracy of the color differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com