Light lath for building partition wall

A slatted, lightweight technology, applied in the direction of construction, building components, building structure, etc., can solve problems such as bonding cracking, and achieve the effect of simple operation, shortened construction period, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further described, but does not make a statement

[0022] limitation of the invention;

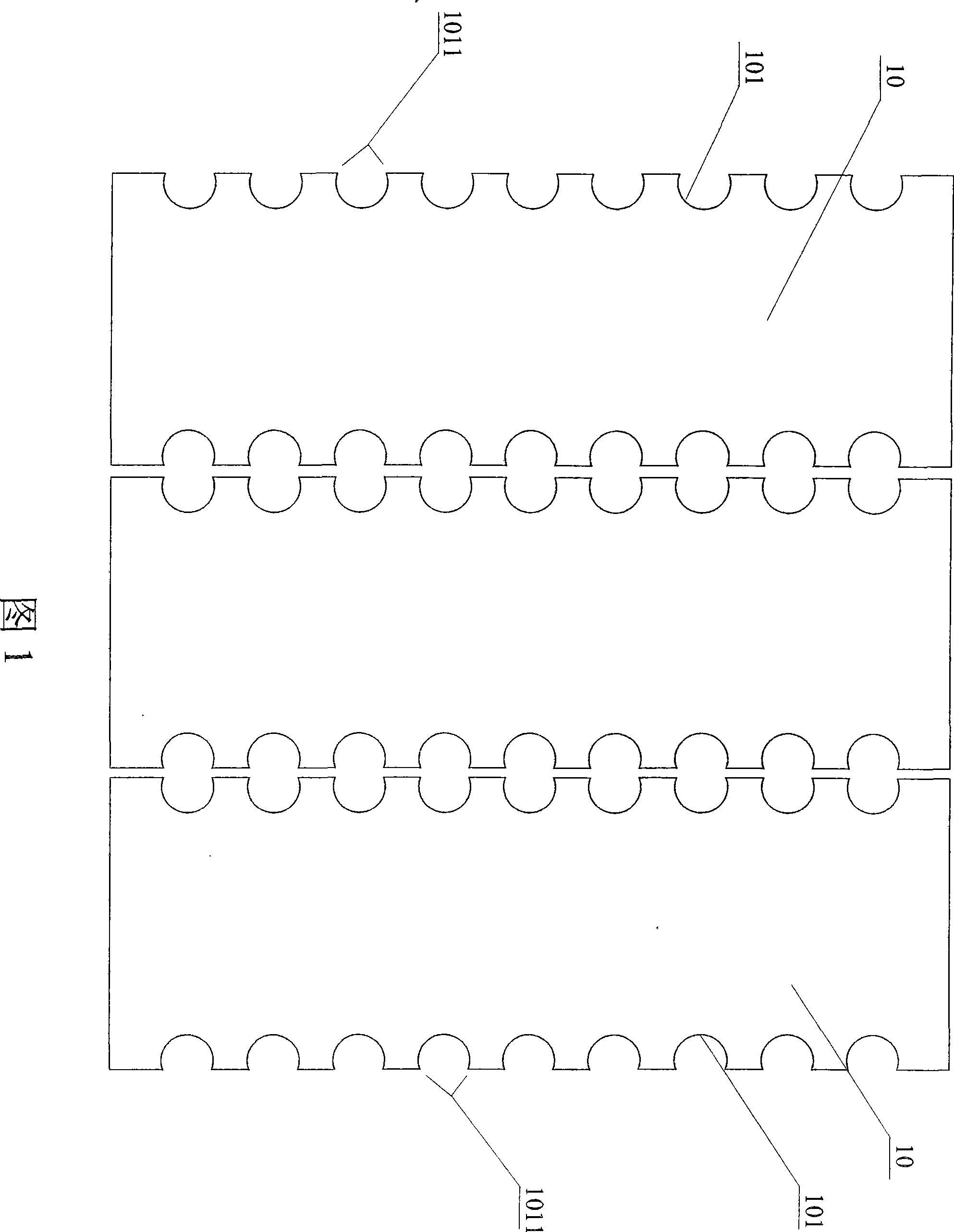

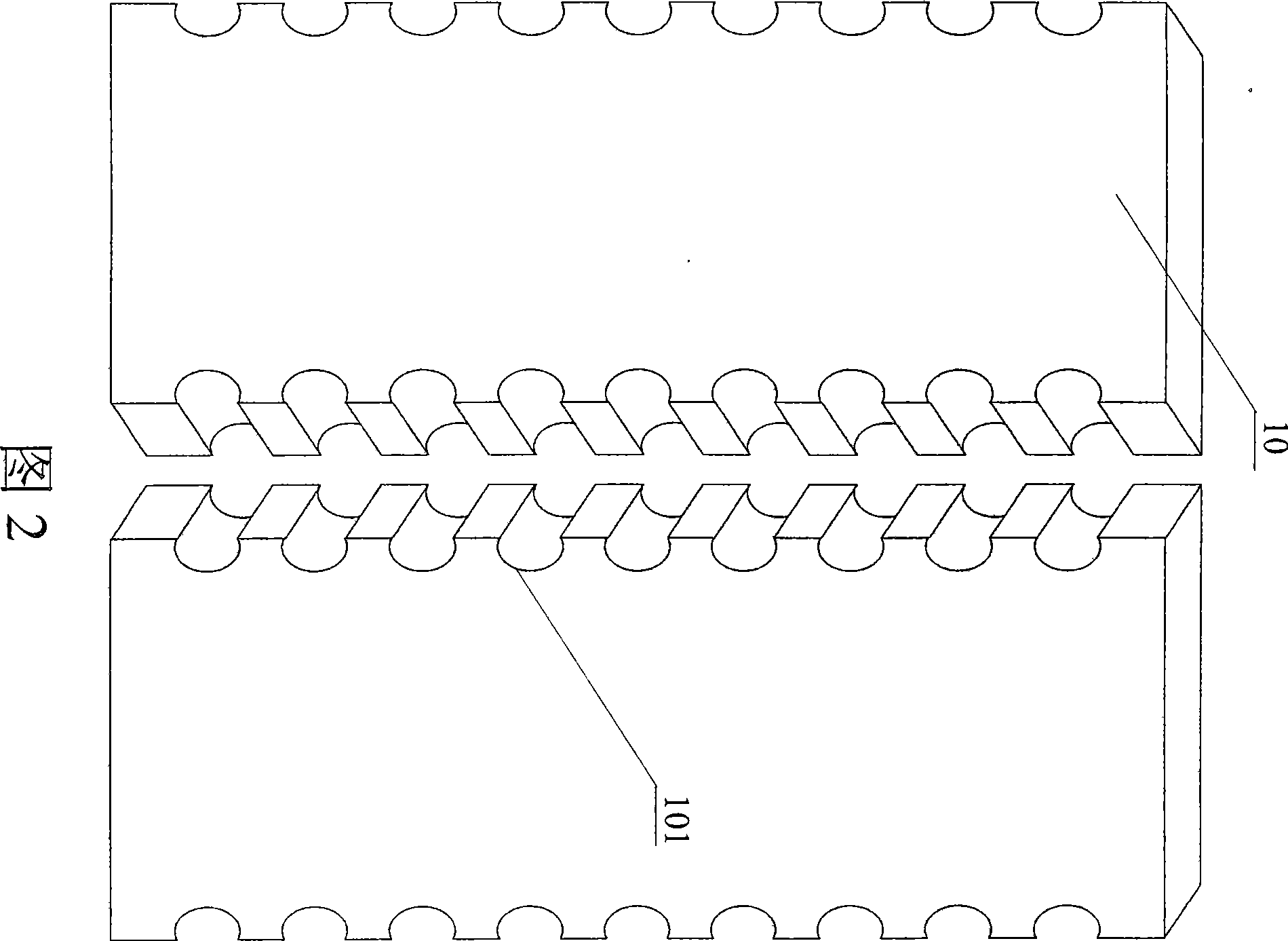

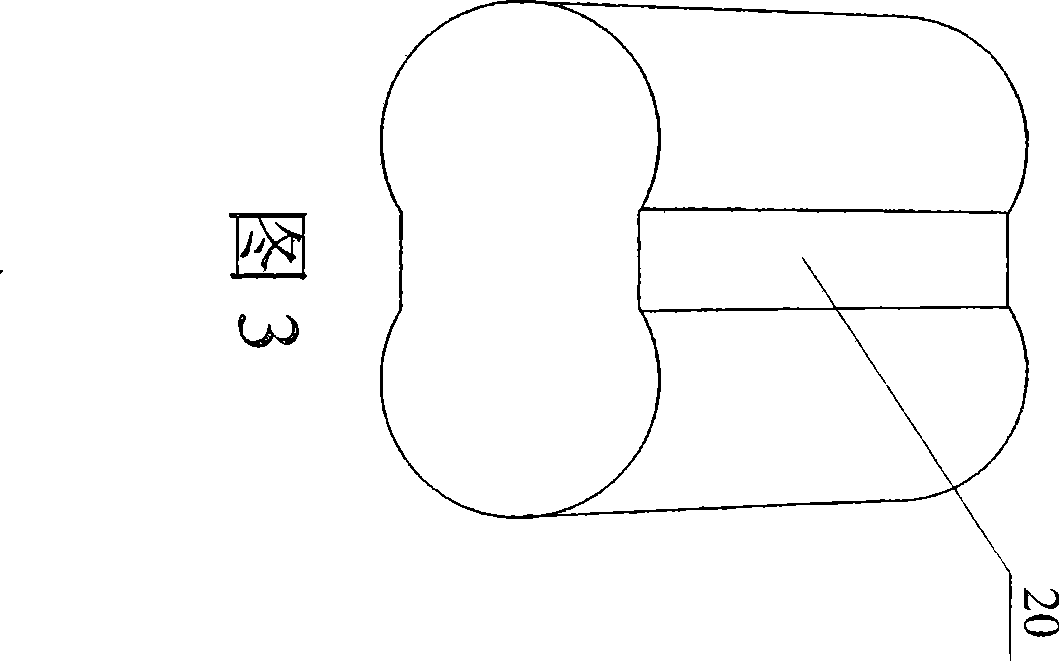

[0023] The first light-weight batten for building partition walls provided by the present invention includes two parts: a main batten and a fixing pin. As shown in Fig. 1 and Fig. 2; its two sides of the main strip (10) are symmetrically and evenly formed with some semi-cylindrical slots (101) perpendicular to the board surface respectively. The upper and lower distance (1011) of the outer notch of the semi-cylindrical slot (101) should be smaller than the diameter of the semi-cylindrical slot (101). As shown in Figure 3; fixed pin (20) is the symmetrical compound of two main strips (10) semi-cylindrical slots (101) and is double semi-cylindrical, and its size and shape meet the following conditions; when above-mentioned Fig. 1, When the two main strips (10) shown in Figure 2 are splic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com