Motion sensor temperature drift correction method and system, and electronic device

A motion sensor, temperature drift technology, used in the testing/calibration of speed/acceleration/shock measurement equipment, instruments, speed/acceleration/shock measurement, etc. long-term problems, to achieve high efficiency, solve calibration and compensation problems, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

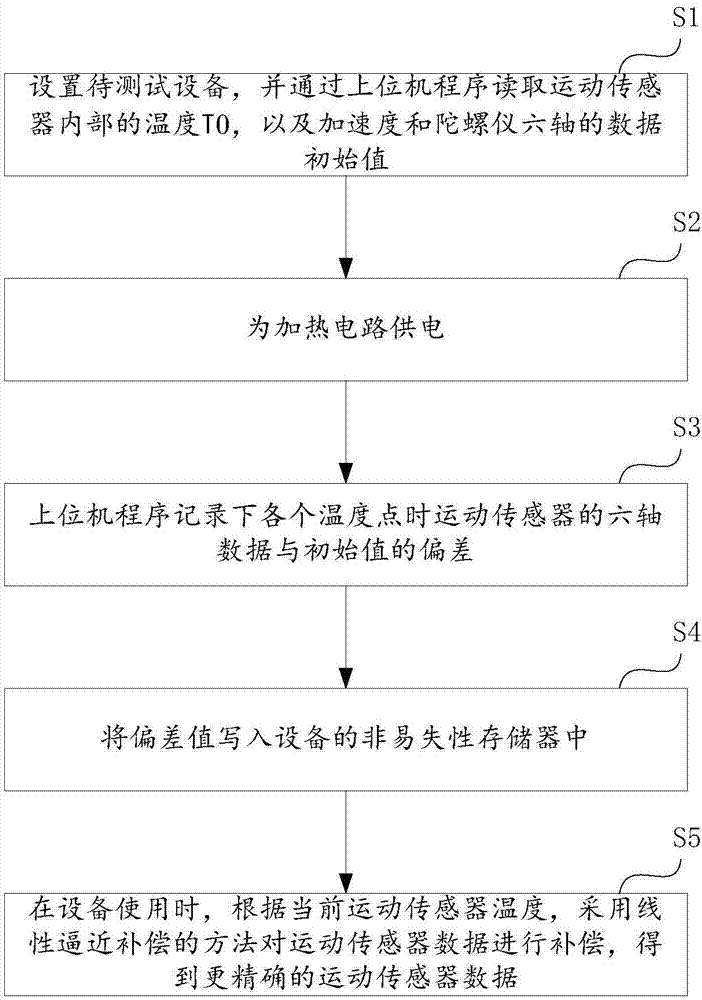

[0042] see figure 1 , the present invention discloses a motion sensor temperature drift correction method, the method comprising:

[0043] [Step S1] When performing temperature drift calibration, place the device to be tested on a horizontal plane, and read the temperature T0 inside the motion sensor, as well as the initial value of the acceleration and six-axis data of the gyroscope through the host computer program; select the appropriate resistance, It can easily reach a temperature of 80 degrees Celsius in 10 seconds.

[0044] [Step S2] The production fixture supplies power to the heating circuit through test points TP1 and TP2. In this embodiment, the heating circuit is independent of the motion sensor circuit and connected to the test point. During production, the test point of the fixture supplies power to the heating circuit to realize rapid heating; the heating circuit adopts a surface-mounted power resistor, and In order to heat up quickly, it is isolated from the ...

Embodiment 2

[0049] The present invention discloses a temperature drift correction method for a motion sensor, the method comprising:

[0050]Step S1, set the device to be tested, and read the temperature T0 inside the motion sensor, as well as the initial value of the acceleration and six-axis data of the gyroscope through the host computer program;

[0051] Step S2, supplying power to the heating circuit;

[0052] Step S3, the upper computer program records the deviation between the six-axis data of the motion sensor and the initial value at each temperature point;

[0053] Step S4, writing the deviation value into the memory of the device;

[0054] Step S5. When the device is in use, according to the current temperature of the motion sensor, the motion sensor data is compensated by a linear approximation compensation method to obtain more accurate motion sensor data.

Embodiment 3

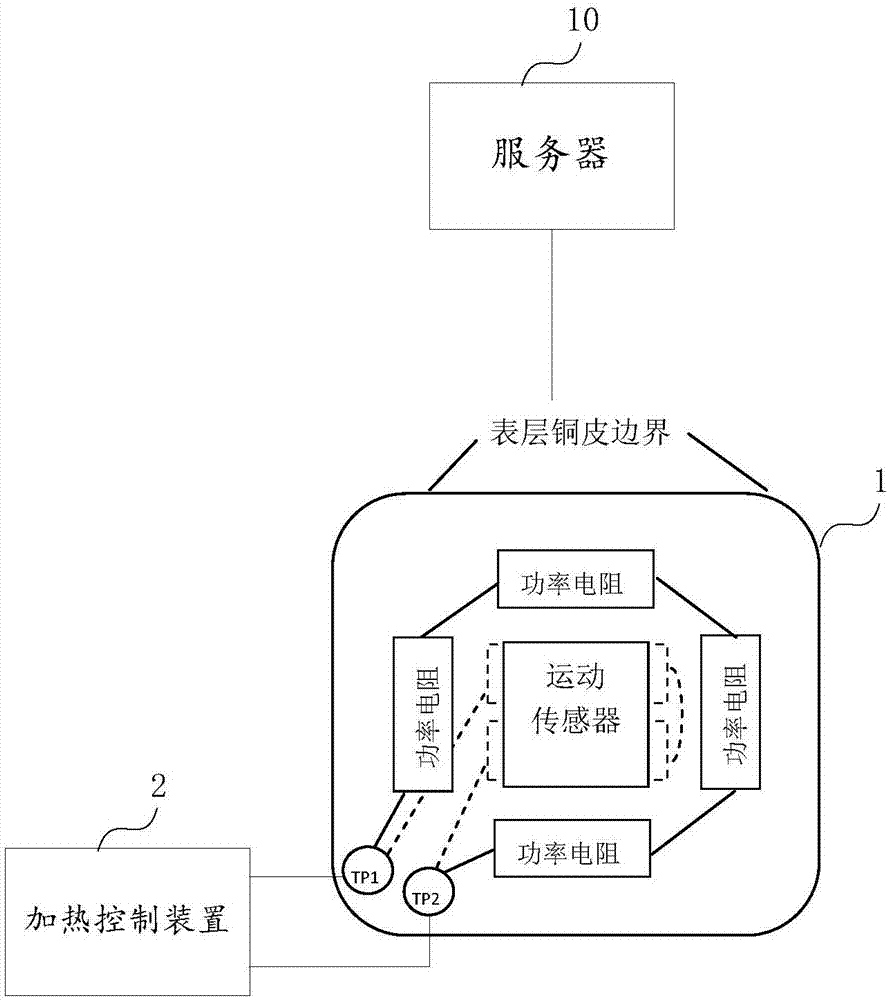

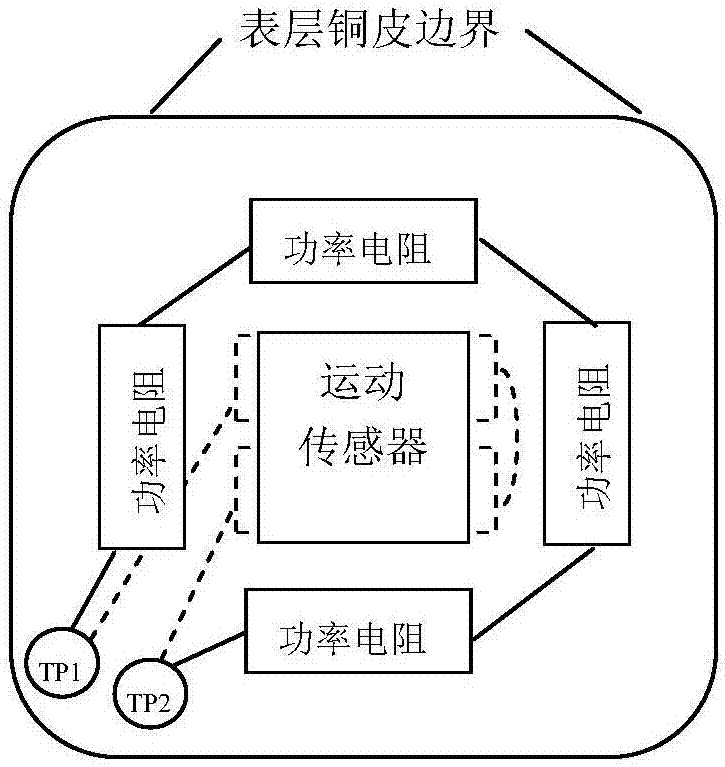

[0056] see figure 2 , the present invention discloses a motion sensor temperature drift correction system, the system includes: a server 10 , an electronic device 1 , and a heating control device 2 .

[0057] The electronic device 1 includes a memory, a motion sensor, a temperature sensor, a heating circuit arranged close to the motion sensor, and a temperature compensation module.

[0058] The heating control device 2 supplies power to the heating circuit 1; the temperature sensor is used to sense the real-time temperature data of the motion sensor, and when the deviation data is obtained, the temperature data is fed back to the server, and the sensed data is sent to the server when the device is in use to the temperature compensation module.

[0059] The server 10 is connected to the electronic device, records the deviation between the six-axis data of the motion sensor and the initial value at each temperature point; and writes the deviation value into the non-volatile me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com