Patents

Literature

30results about How to "Solving Compensation Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

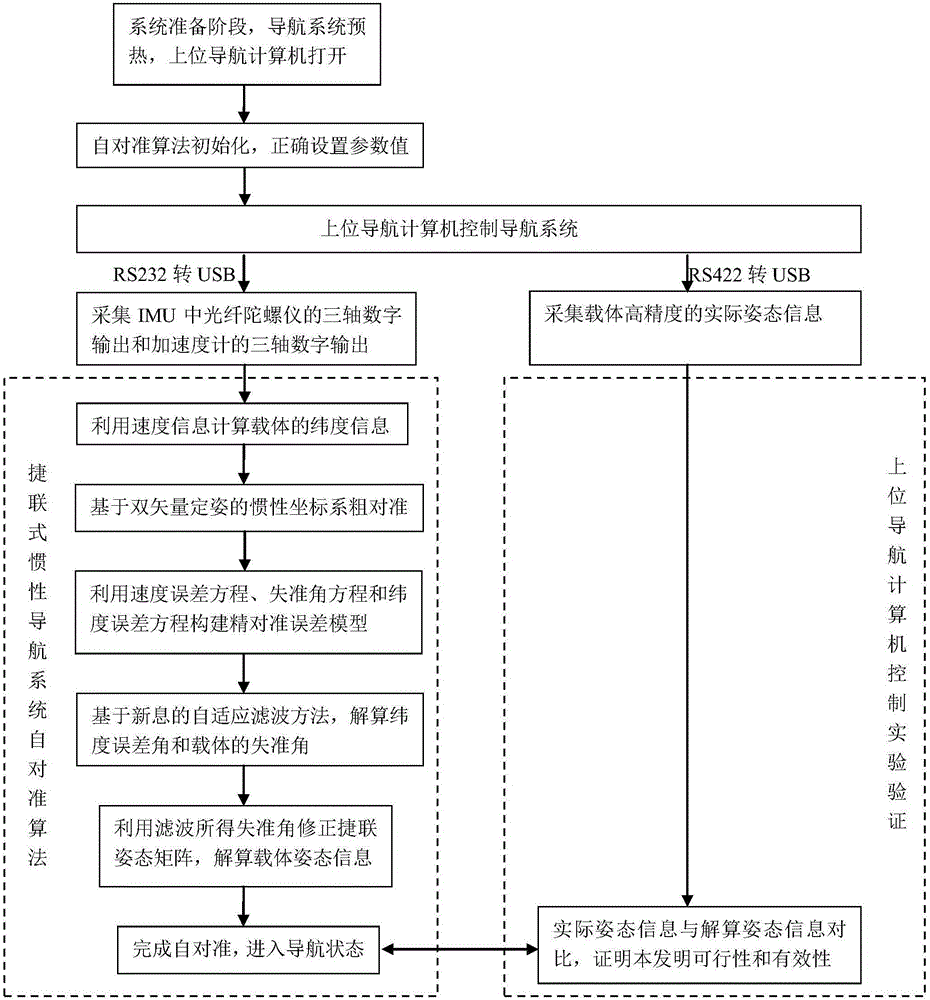

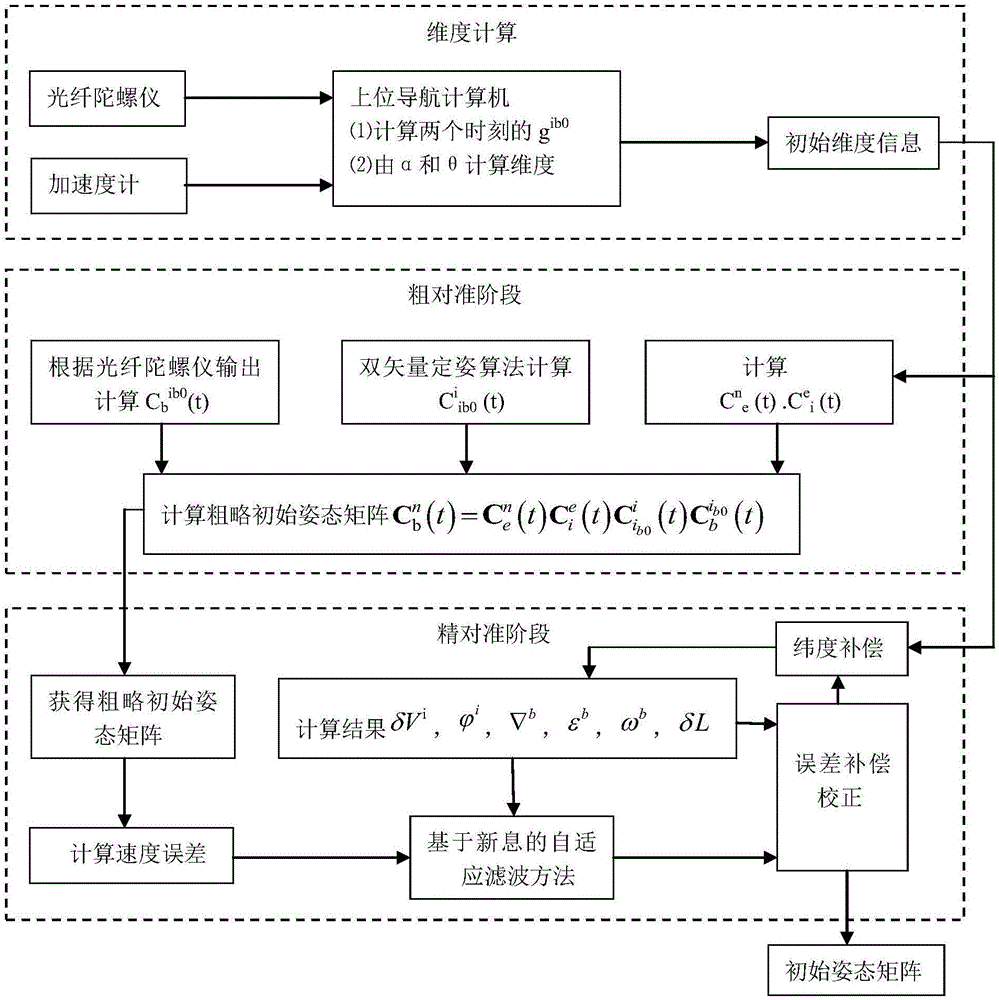

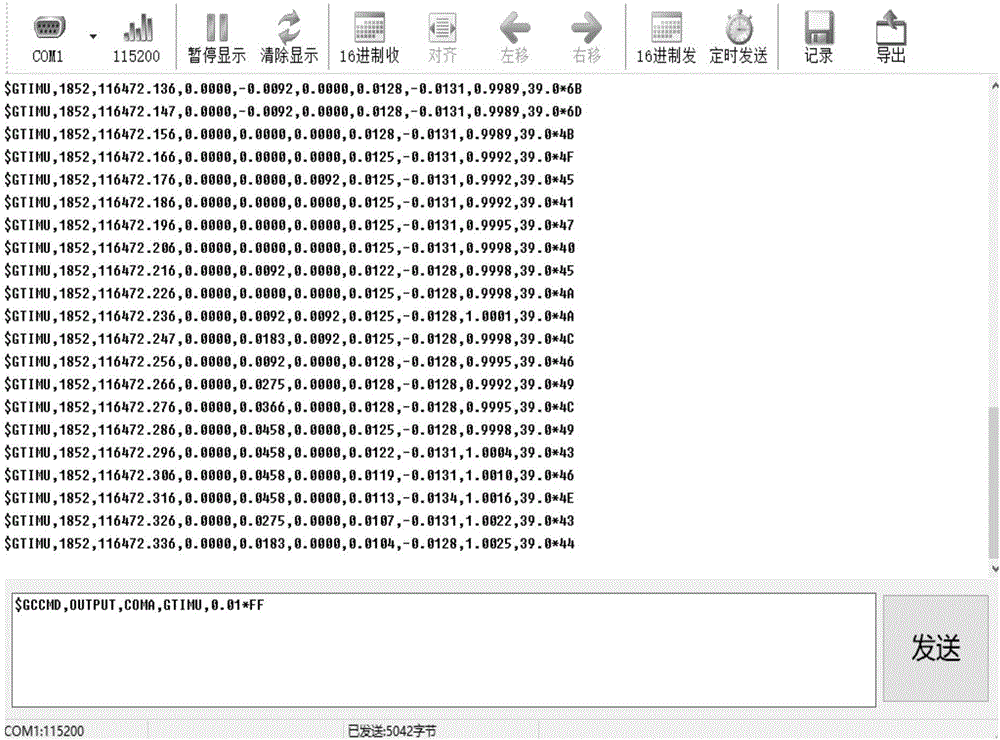

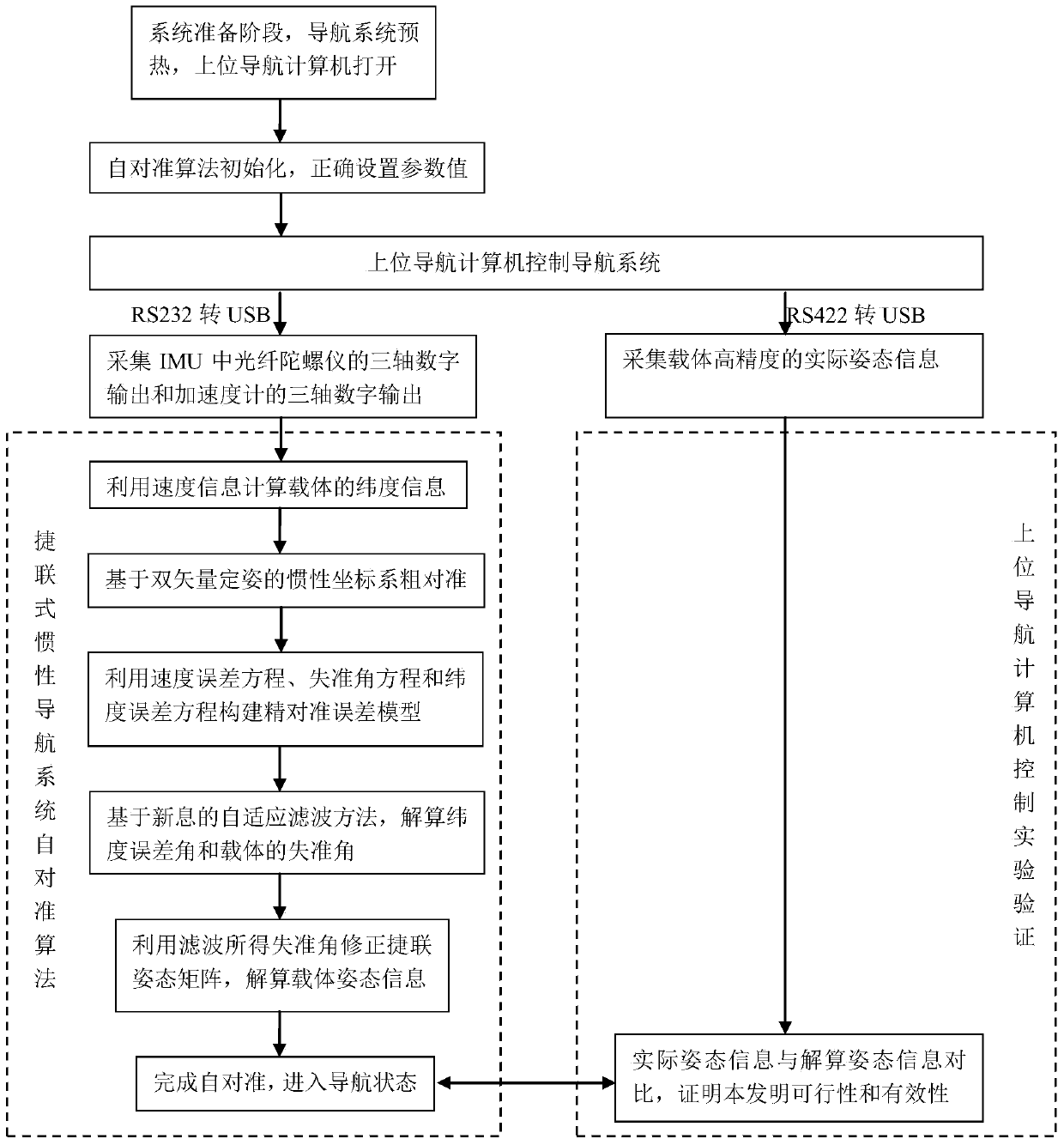

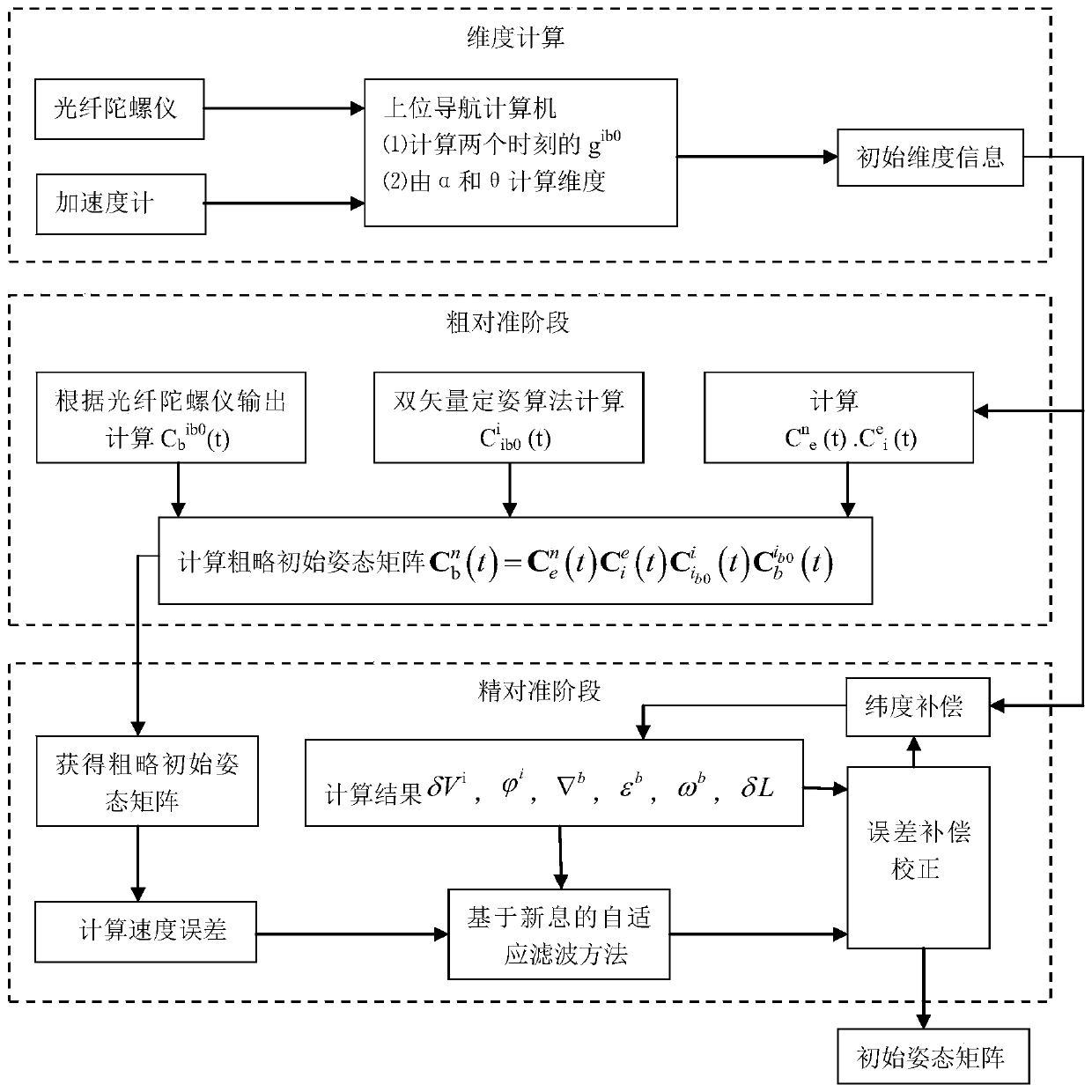

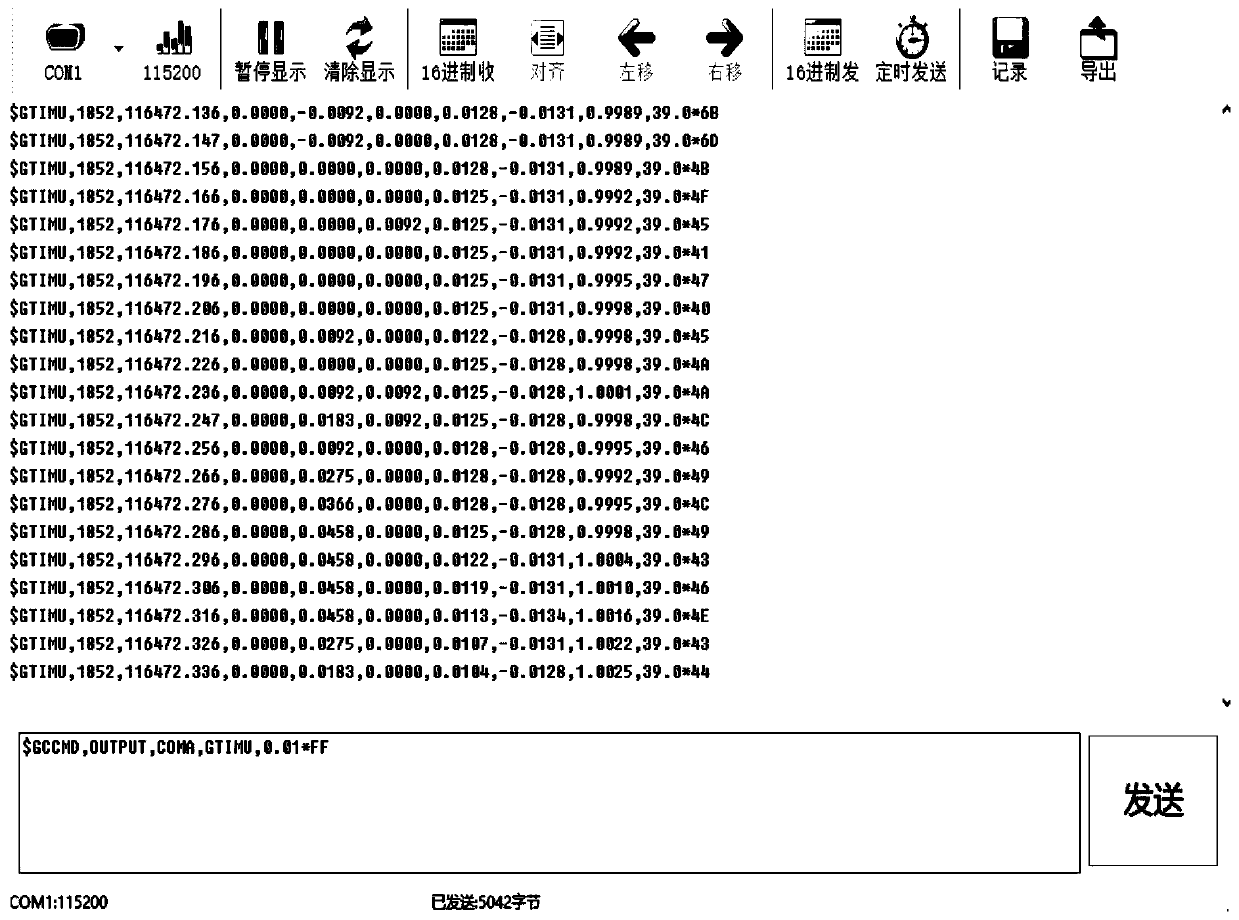

Latitude unknown self-aligning method of strapdown inertial navigation system under dynamic interference condition

ActiveCN106123921AGuaranteed accuracyGuaranteed validityNavigation by speed/acceleration measurementsInertial coordinate systemSelf adaptive

A latitude unknown self-aligning method of a strapdown inertial navigation system under the dynamic interference condition includes the steps that firstly, a geometrical analytic formula is built by means of the characteristic that the projection of gravity acceleration is unchanged in an inertial coordinate system, the gravity acceleration is subjected to integration to obtain speed information, and the latitude value of the position where a carrier is located is calculated according to the speed information; secondly, on the basis of the double-vector altitude determination principle and by means of the characteristic that the gravity acceleration of an inertial system includes north orientation information, rough solution of an initial attitude matrix under the inertial system is achieved; finally, on the basis that coarse alignment is finished, a precise alignment error model under the latitude unknown dynamic interference condition is built according to a speed error equation, a misalignment angle equation and a latitude error equation, the latitude error angle and the misalignment angle of the carrier are calculated by means of the self-adaptive filtering method based on information, the latitude value is compensated with the latitude error angle, the strapdown altitude matrix is corrected according to the misalignment angle, and high-precision quick self-aligning of the strapdown inertial navigation system is achieved.

Owner:BEIJING UNIV OF TECH

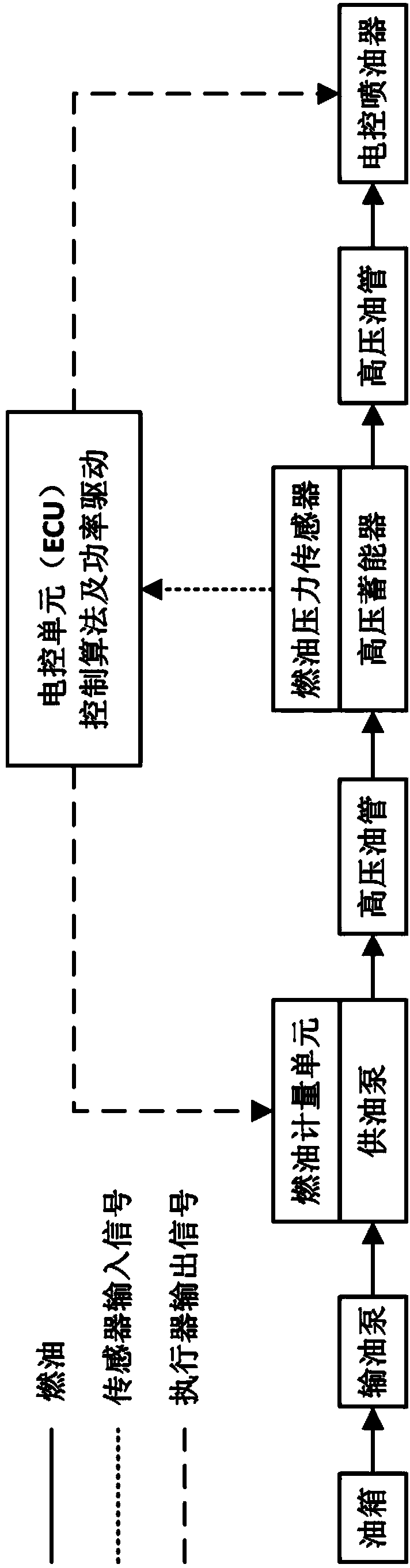

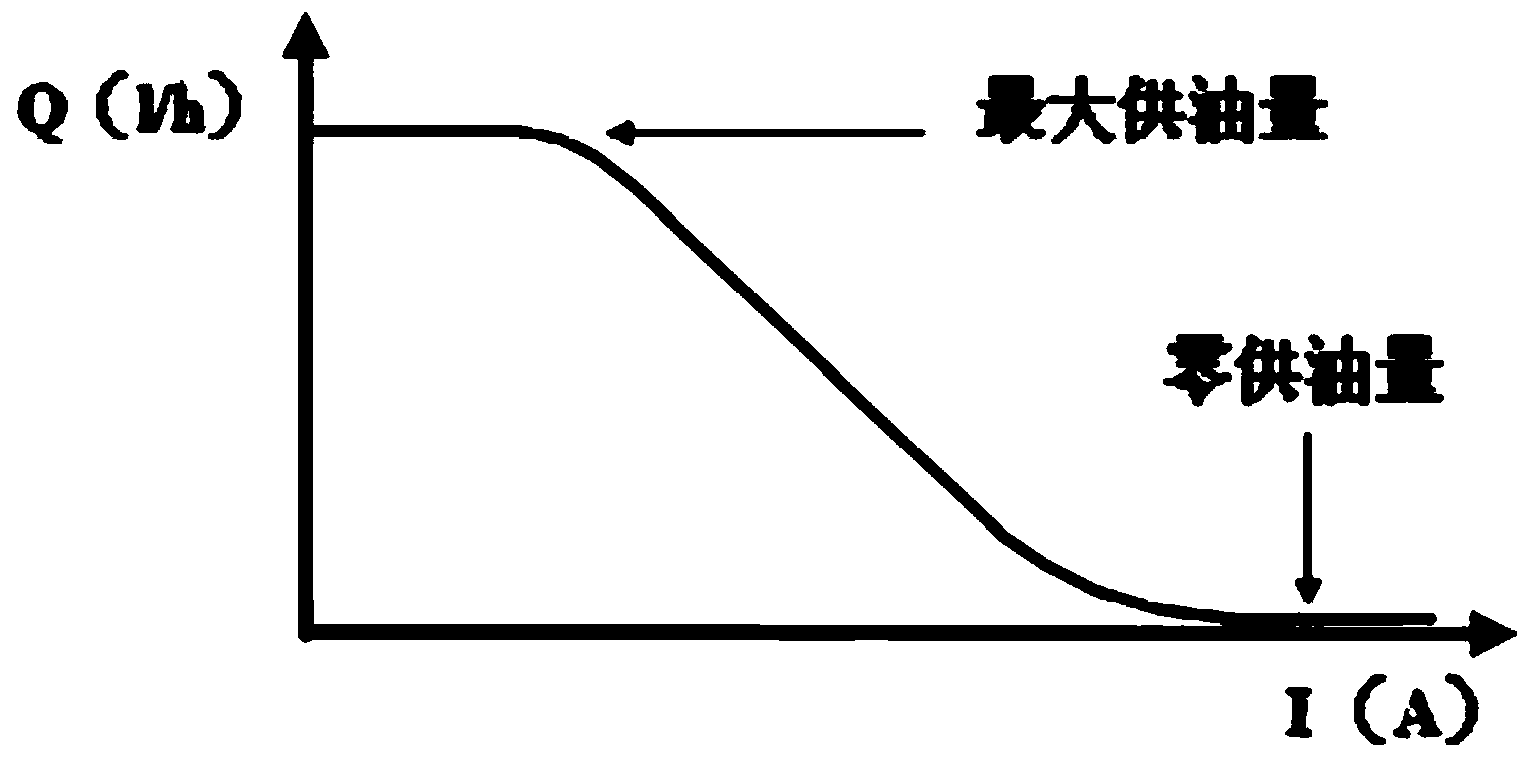

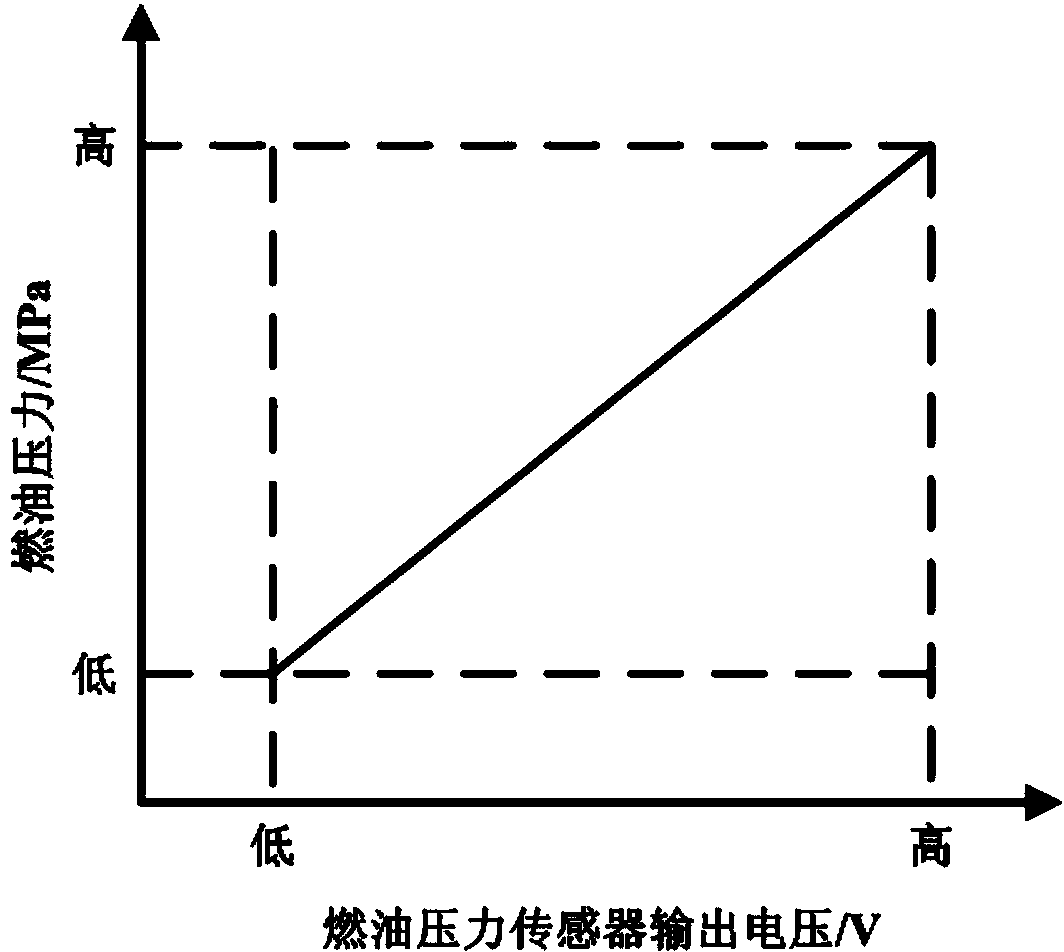

Active disturbance observation-based fuel pressure controller and control method thereof

The invention relates to an active disturbance observation-based fuel pressure control method, aims at solving the problems of time-varying characteristics and non-linearity of an internal combustion engine fuel injection system and non-ideal application of traditional PID (proportion integration differentiation) control in fuel pressure control and the like, and provides the method of realizing control on fuel pressure by adopting model-based feedforward control and state observation-based feedback control. The method mainly comprises target fuel pressure computation, fuel pressure sensor practical fuel pressure collection and computation, fuel measuring unit fuel volume flow rate feedback regulation amount computation, fuel measuring unit fuel volume flow rate feedforward control amount computation, conversion of fuel measuring unit fuel volume flow rate into current, conversion of fuel measuring unit current into a PWM (Pulse Width Modulation) duty ratio, fuel measuring unit practical work current measurement and computation, a fuel measuring unit current feedback regulator, fuel measuring unit PWM modulation frequency computation, a fuel measuring unit PWM drive, a fuel measuring unit, a fuel injection system and a fuel pressure active disturbance observer.

Owner:TIANJIN UNIV

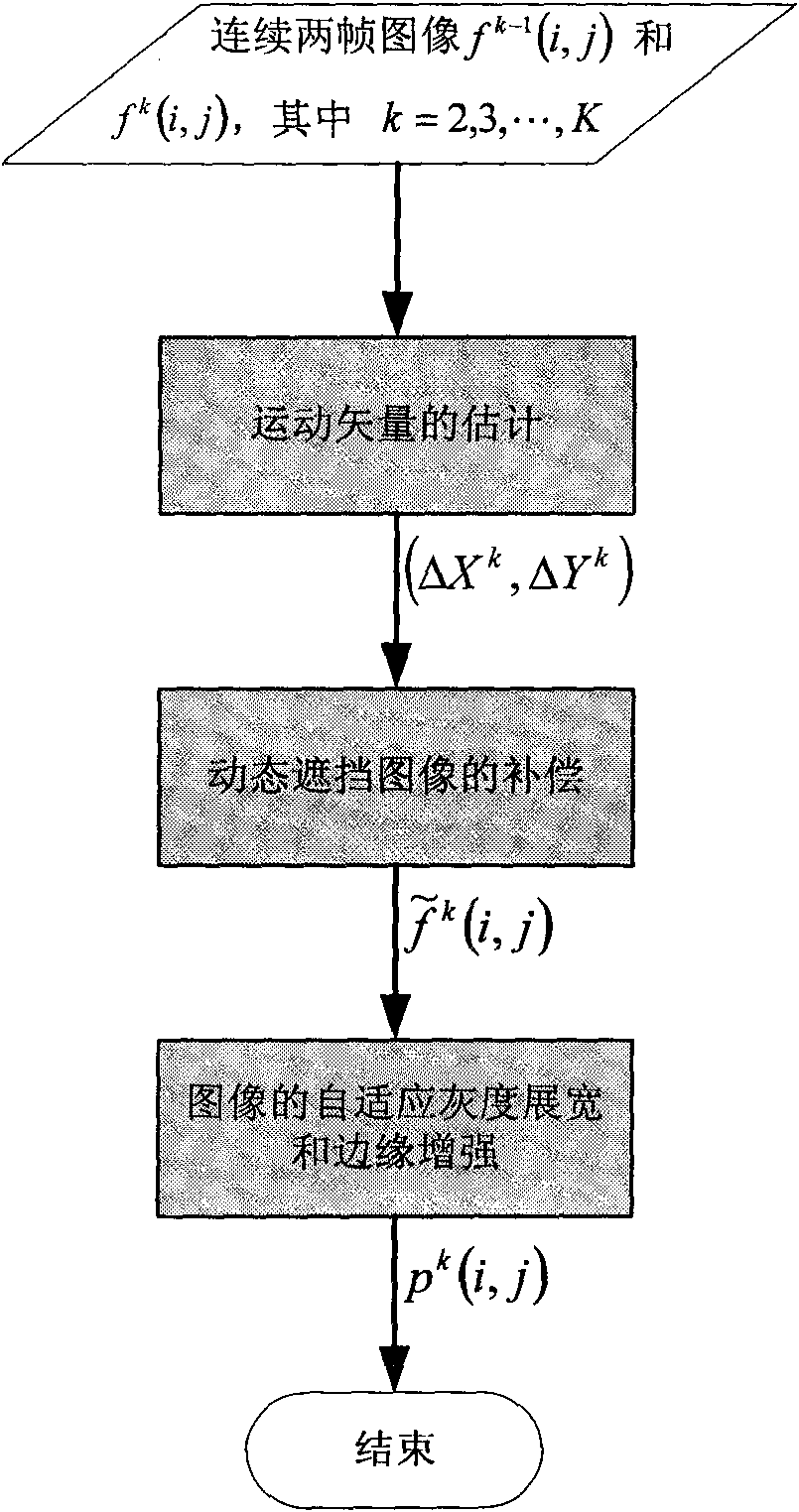

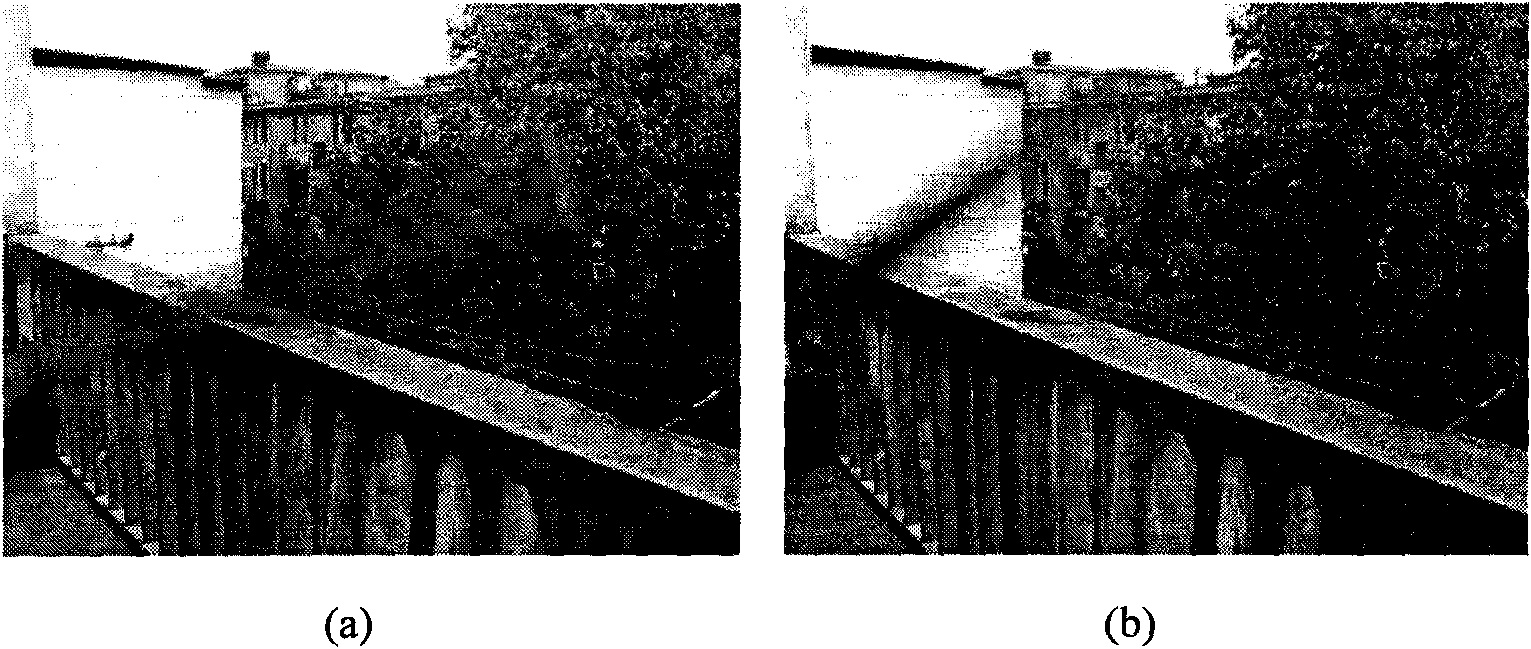

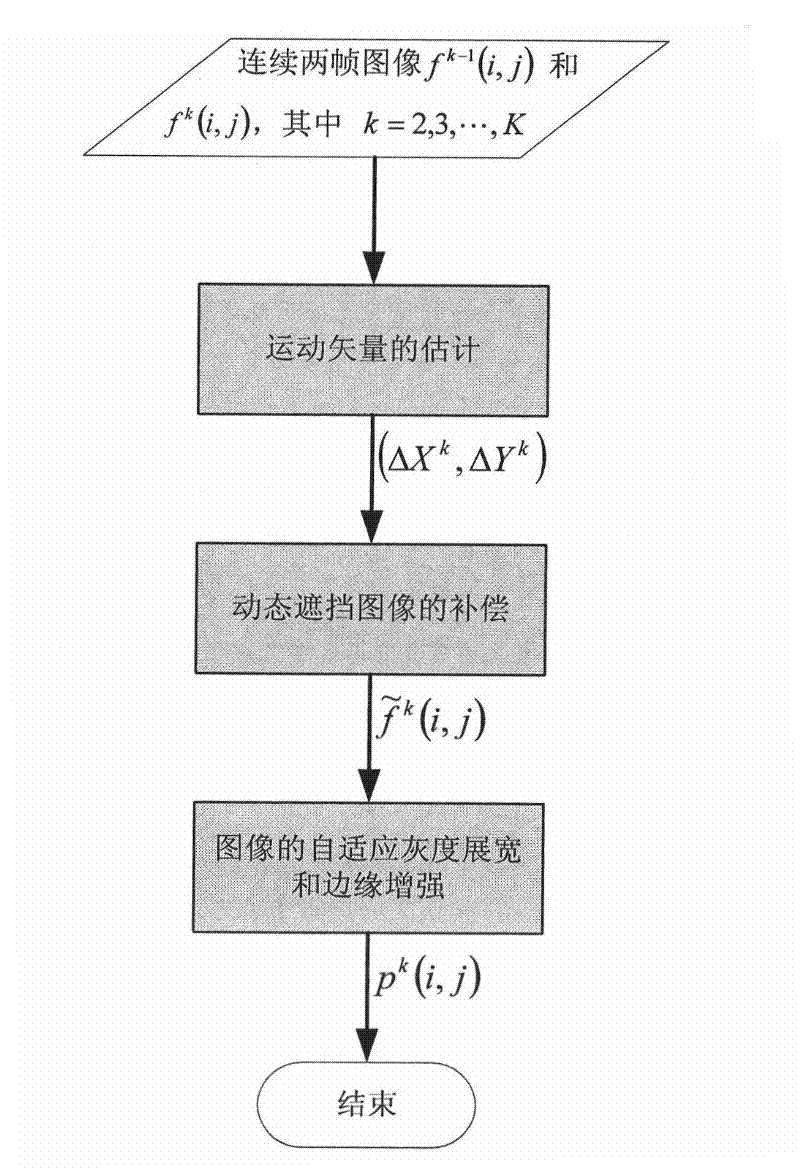

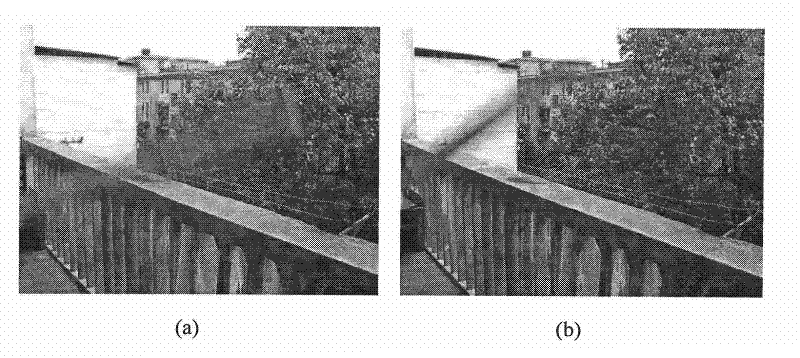

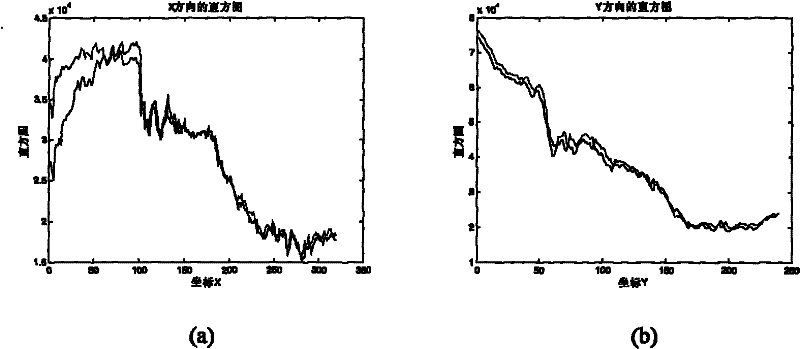

Method for compensating and enhancing dynamic shielded image in real time

InactiveCN101551901AQuality improvementReliable estimateImage enhancementImage analysisTime domainMotion vector

The invention provides a method for compensating and enhancing a dynamic shielded image in real time, solves the real-time compensation and enhancement problems of the dynamic shielded image and improves the quality of the dynamic shielded image. The technical proposal comprises the steps of estimating the motion vector between two adjacent images by a moderate method based on a video image output by a camera, combining motion compensation with a time domain Kalman filter technique of a pixel gray value, performing time domain filtering treatment for all pixels so as to compensate the image information of a dynamic shielded area, and finally performing self-adaptive grey widening and edge enhancement treatments for the compensated image.

Owner:NAT UNIV OF DEFENSE TECH

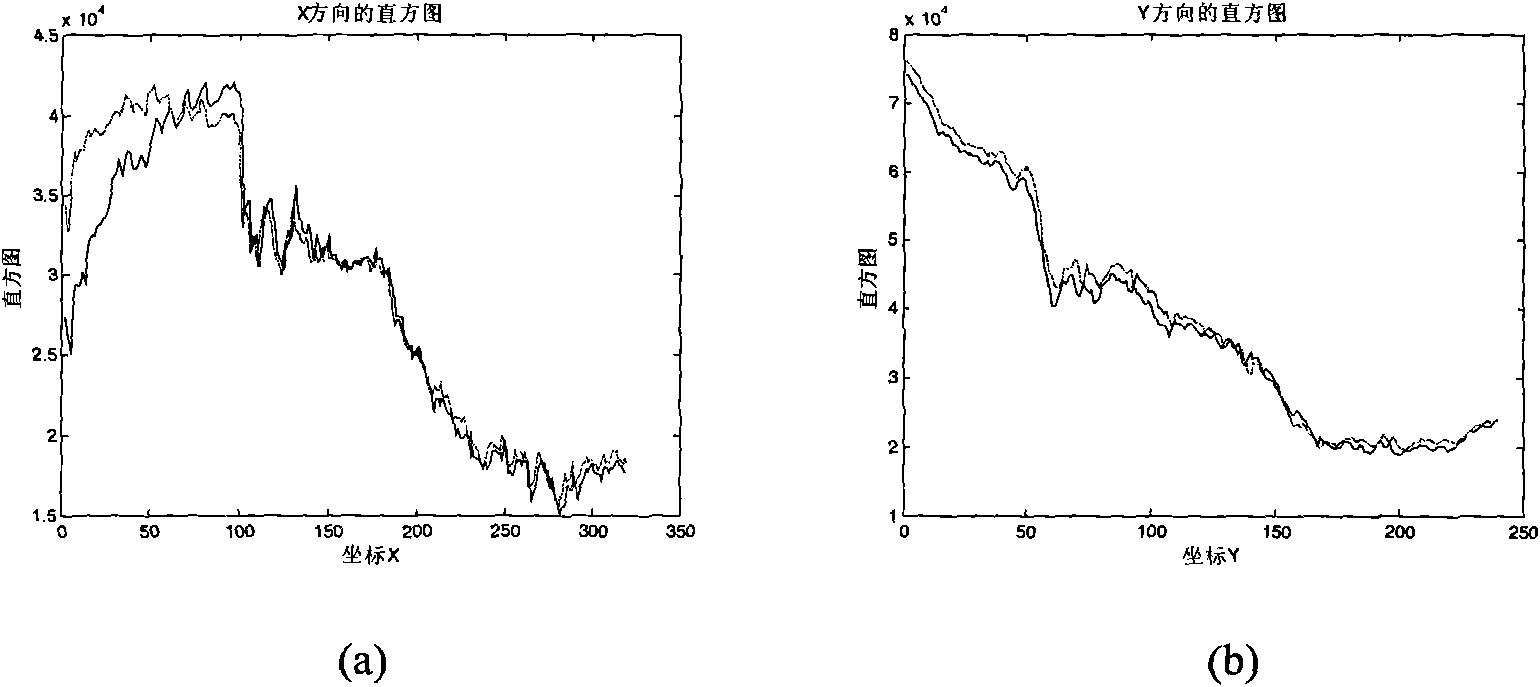

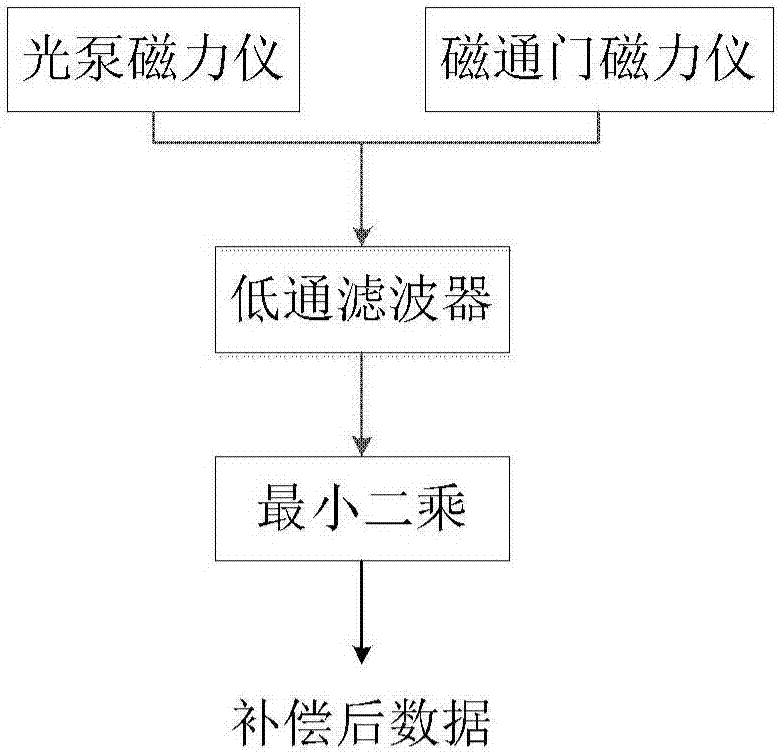

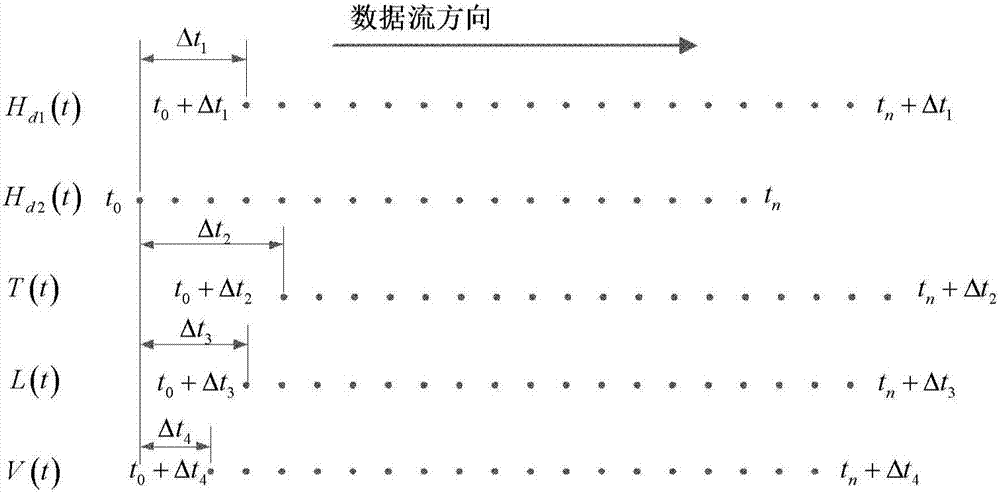

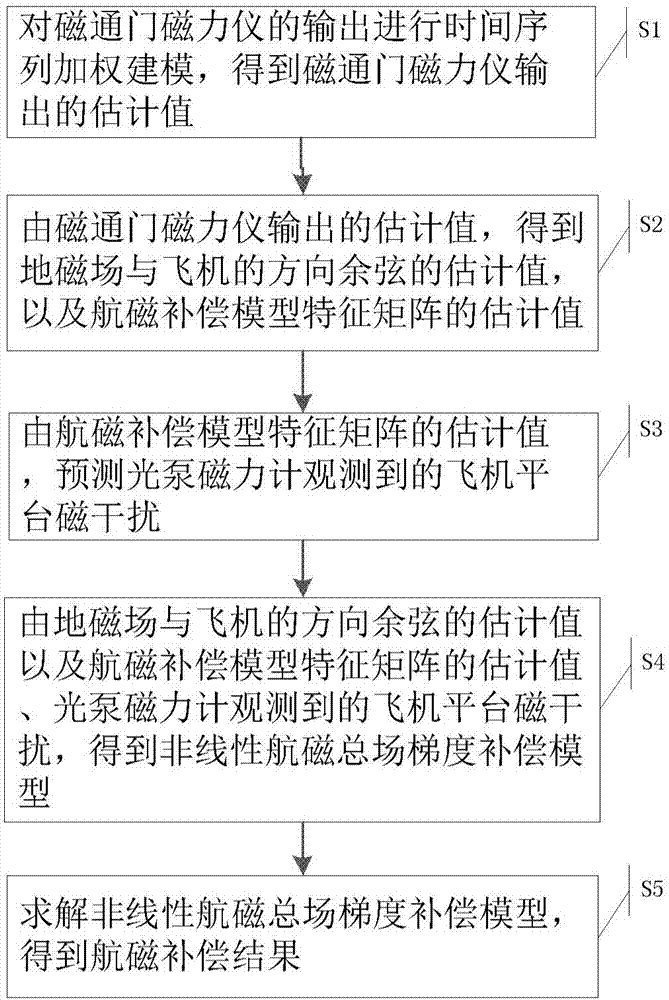

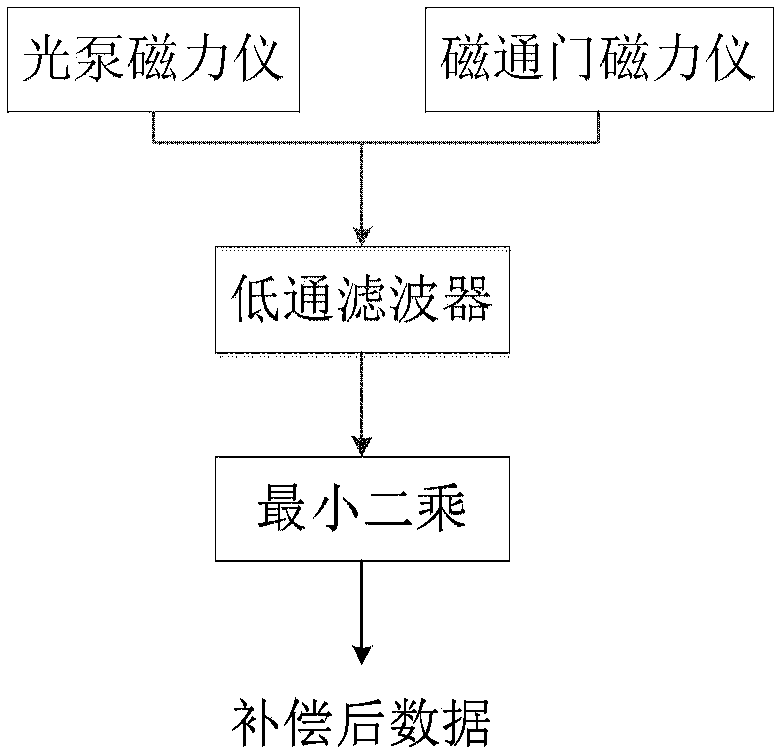

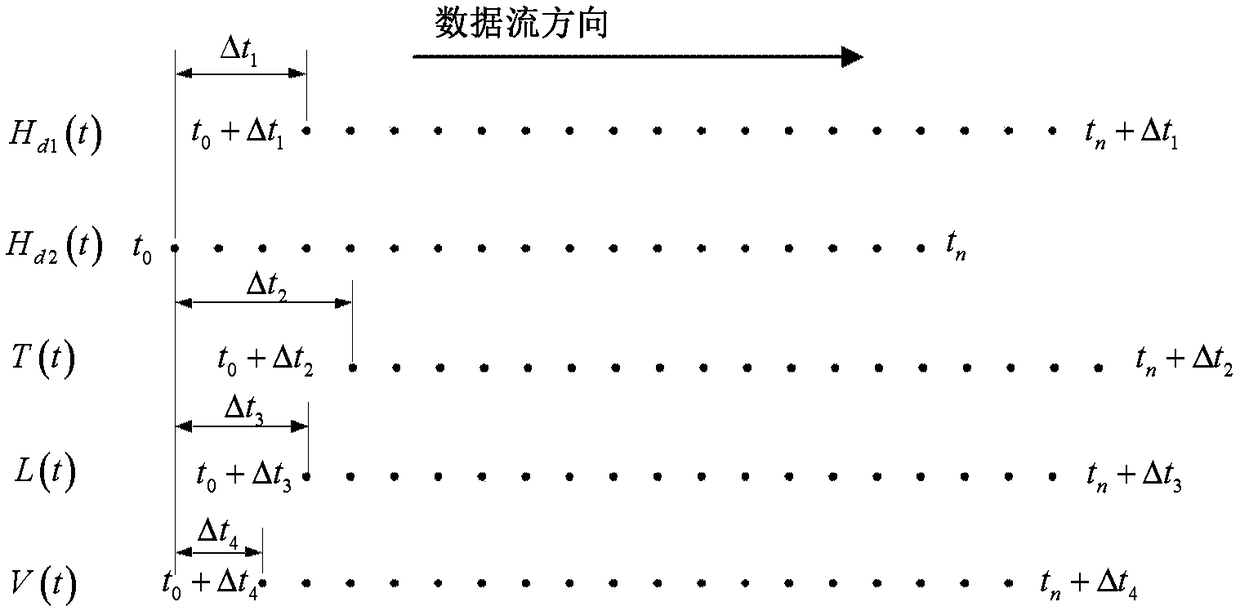

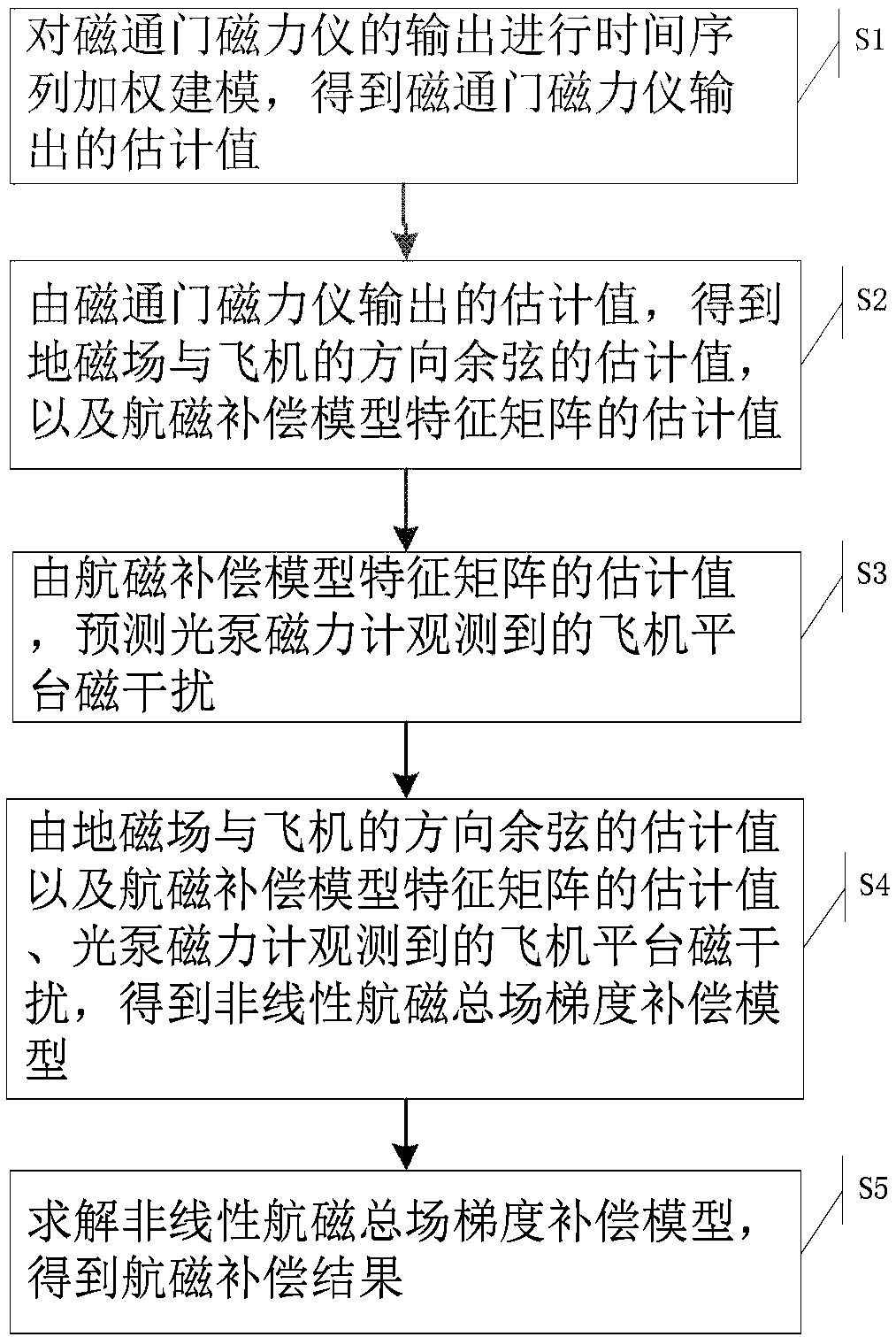

Aeromagnetic compensation method based on non-linear aeromagnetic total field gradient compensation model

ActiveCN106959471ASolve the compensation problem of disturbing magnetic fieldHigh precisionElectric/magnetic detectionAcoustic wave reradiationAirplaneTotal field

The invention provides an aeromagnetic compensation method based on a non-linear aeromagnetic total field gradient compensation model. Time series weighting modeling of output of a flux-gate magnetometer is carried out, and a direction cosine of a geomagnetic field and a direction cosine of an airplane, and an aeromagnetic compensation model characteristic matrix are estimated, and thereafter airplane platform magnetic interferences observed by an optical pump magnetometer is predicted to acquire the non-linear aeromagnetic total field gradient compensation model, and then the non-linear aeromagnetic total field gradient compensation model is solved to acquire an aeromagnetic compensation result. By establishing the non-linear aeromagnetic total field gradient compensation model, a compensation problem of an interference magnetic field caused by time delay between data channels is effectively solved, and the precision of the aeromagnetic compensation is greatly improved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

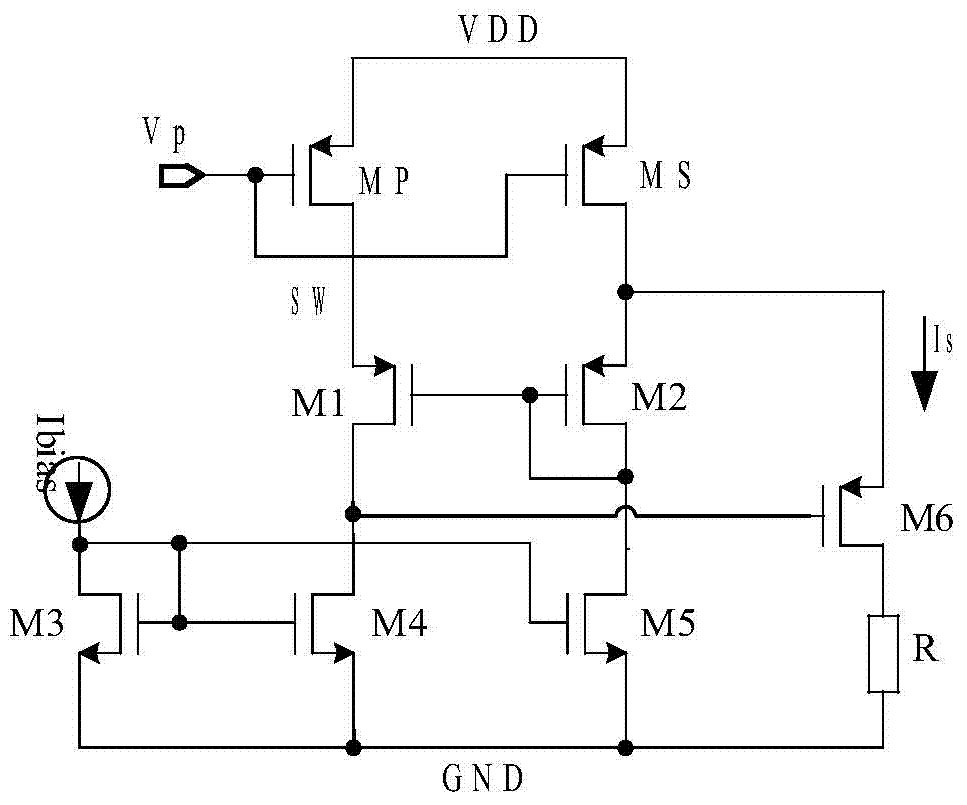

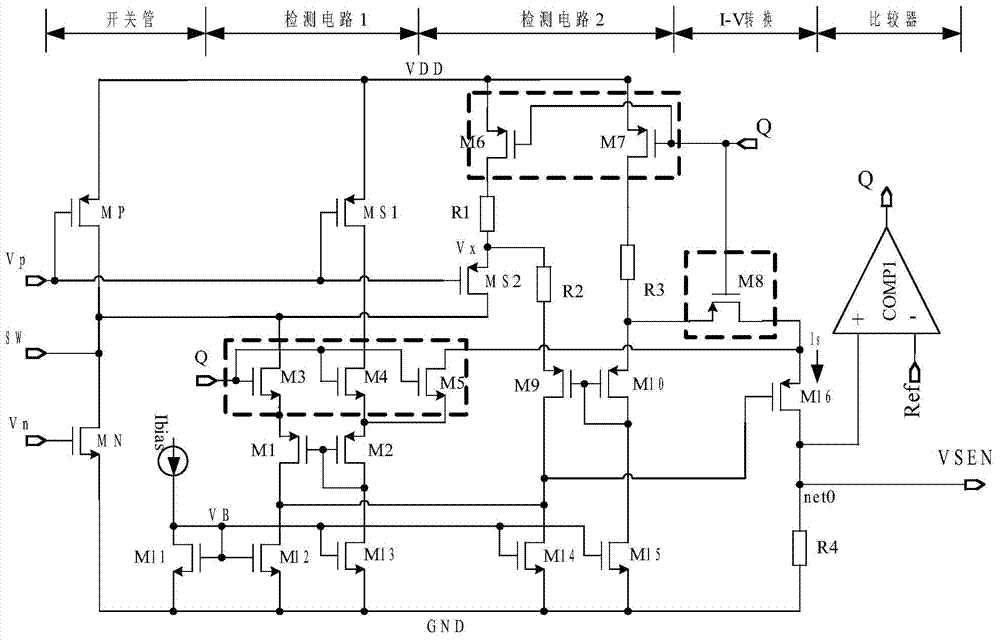

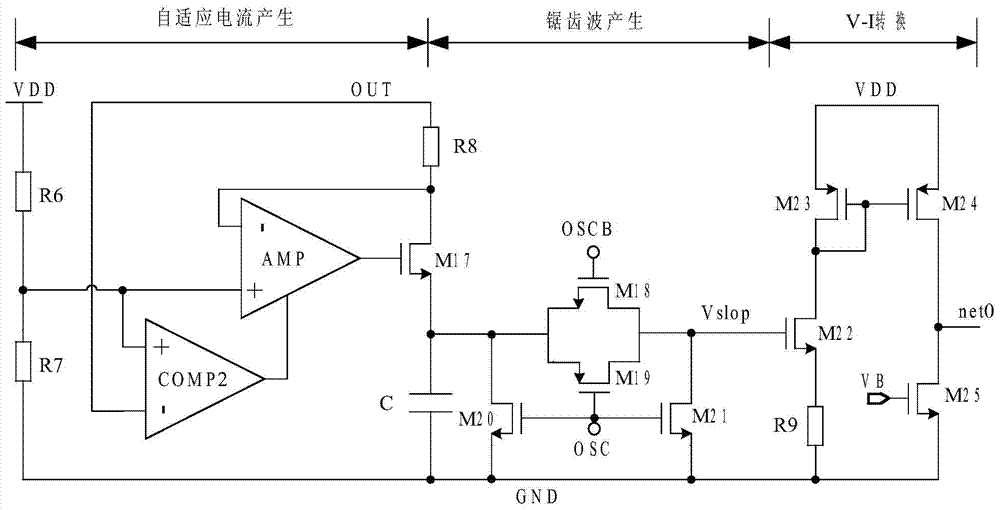

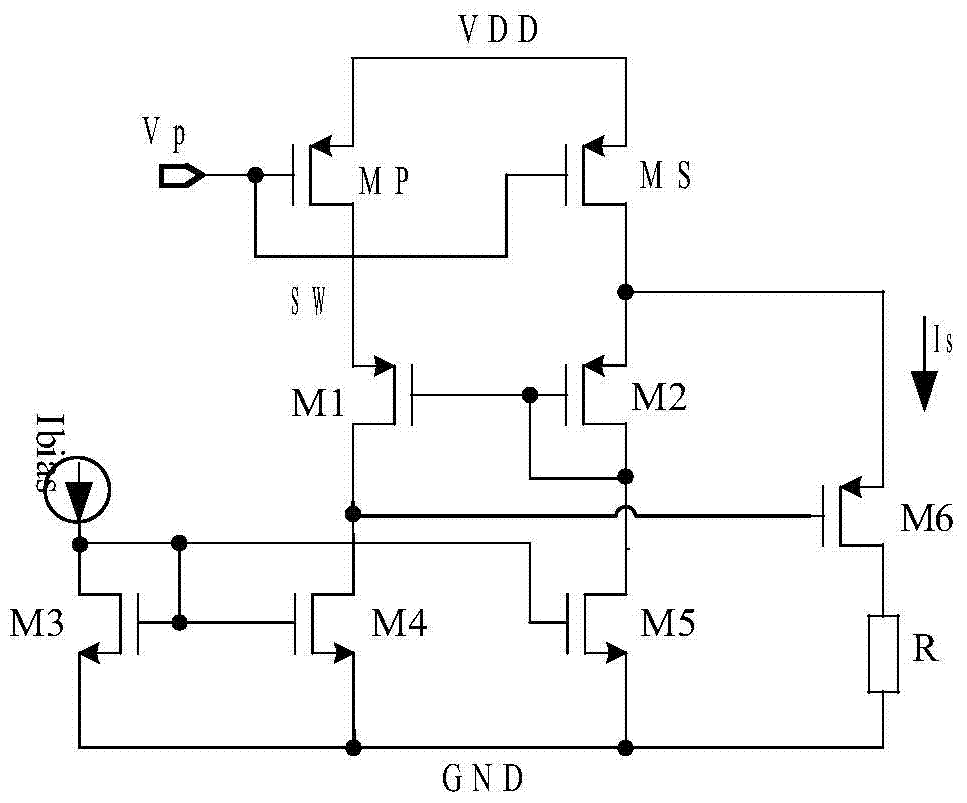

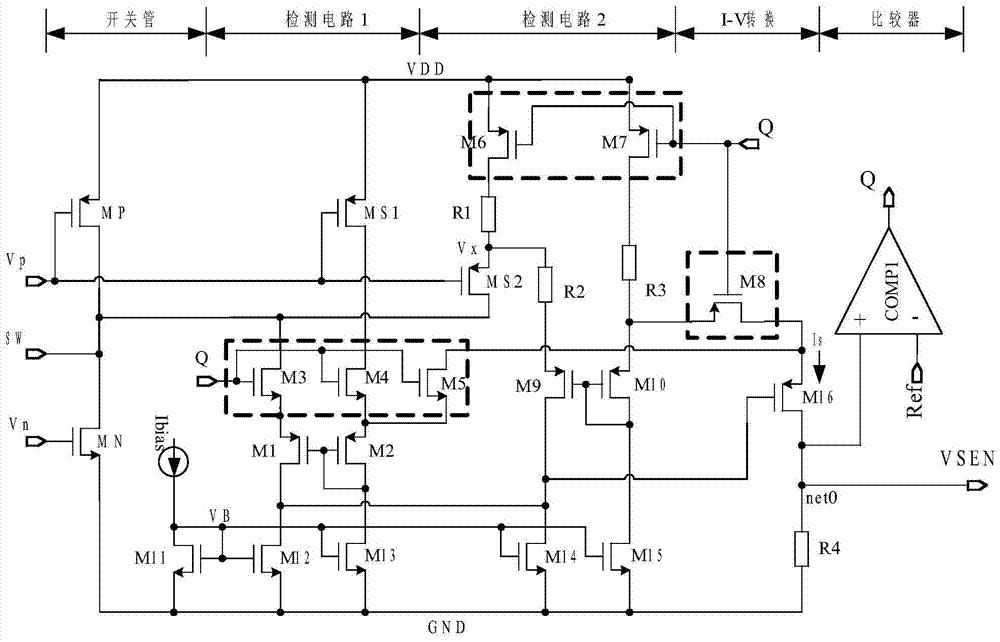

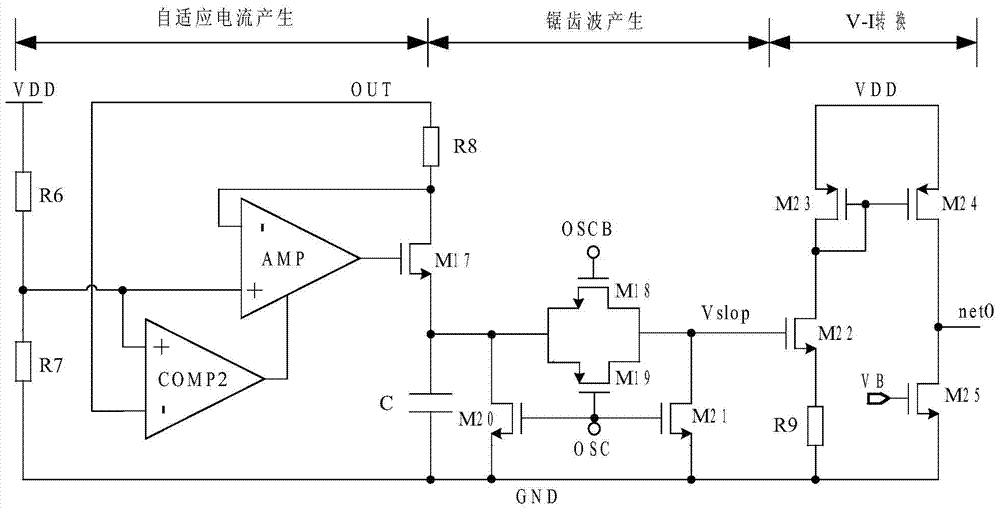

A current detection circuit and an electric current loop control circuit comprising the current detection circuit

ActiveCN104300792AHigh precisionReduce power consumptionEfficient power electronics conversionCurrent/voltage measurementCMOSLoop control

The invention relates to the field of CMOS integrated circuit design and especially relates to a current detection circuit and an electric current loop control circuit comprising the current detection circuit. Through arranging a parallelly-connected MOS transistor current detection circuit and a series resistor current detection circuit, circuit power consumption is reduced at the same time current detection precision is improved; and by utilizing a self-adaption slope compensation circuit, the problem of overcompensation can be further prevented; and detection signals and compensation signals of the circuit can be added directly, thereby facilitating the design of a current-mode DC-DC circuit.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

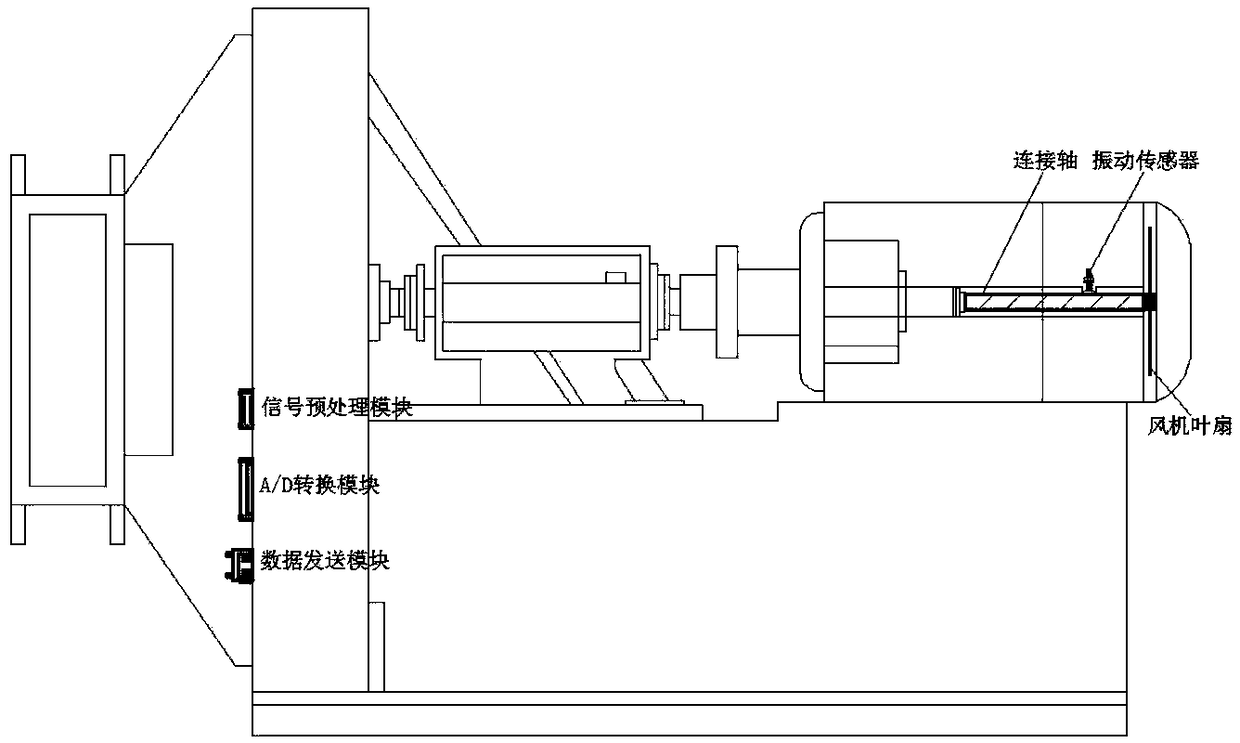

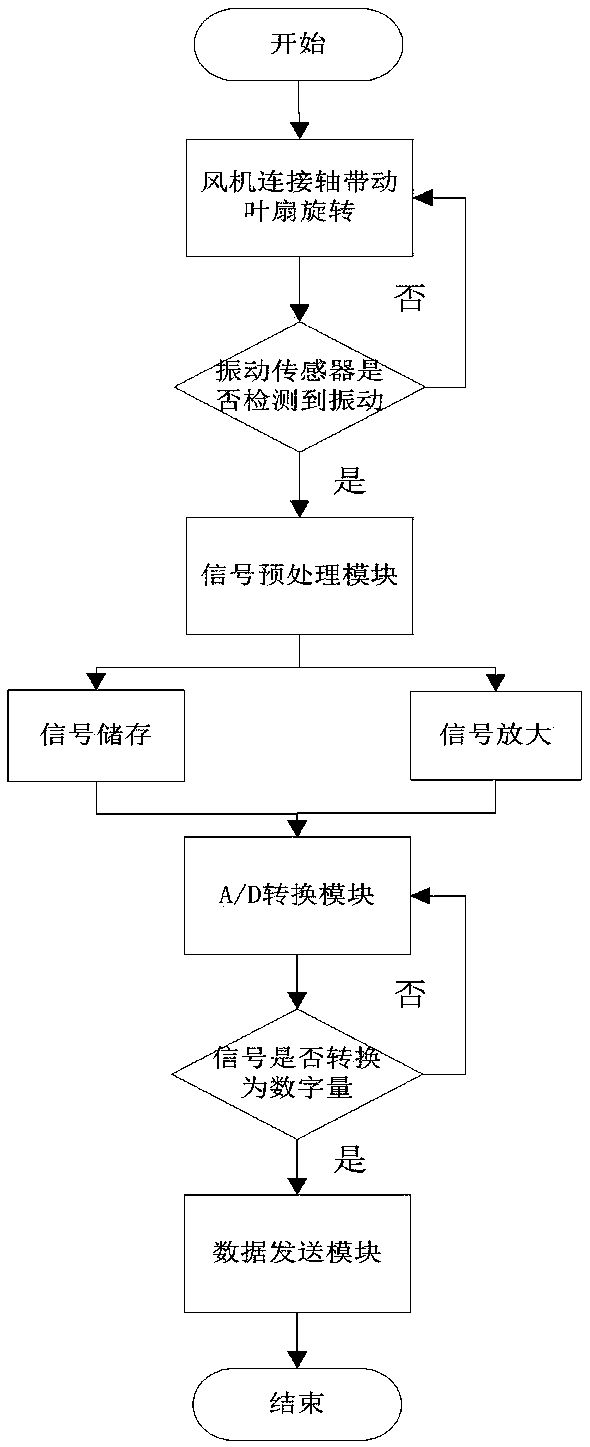

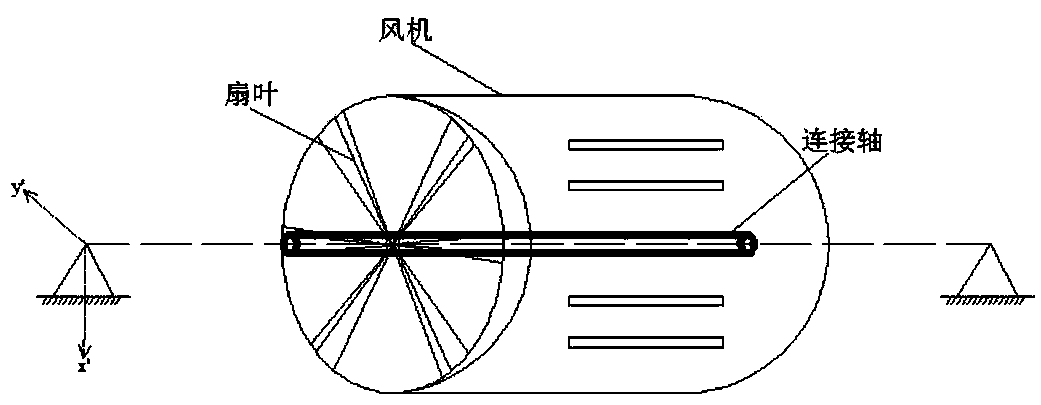

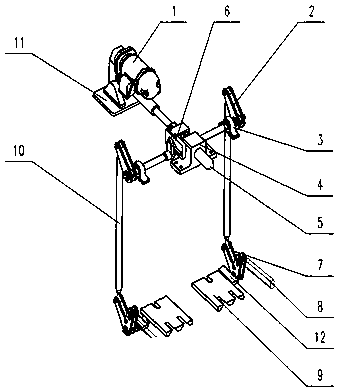

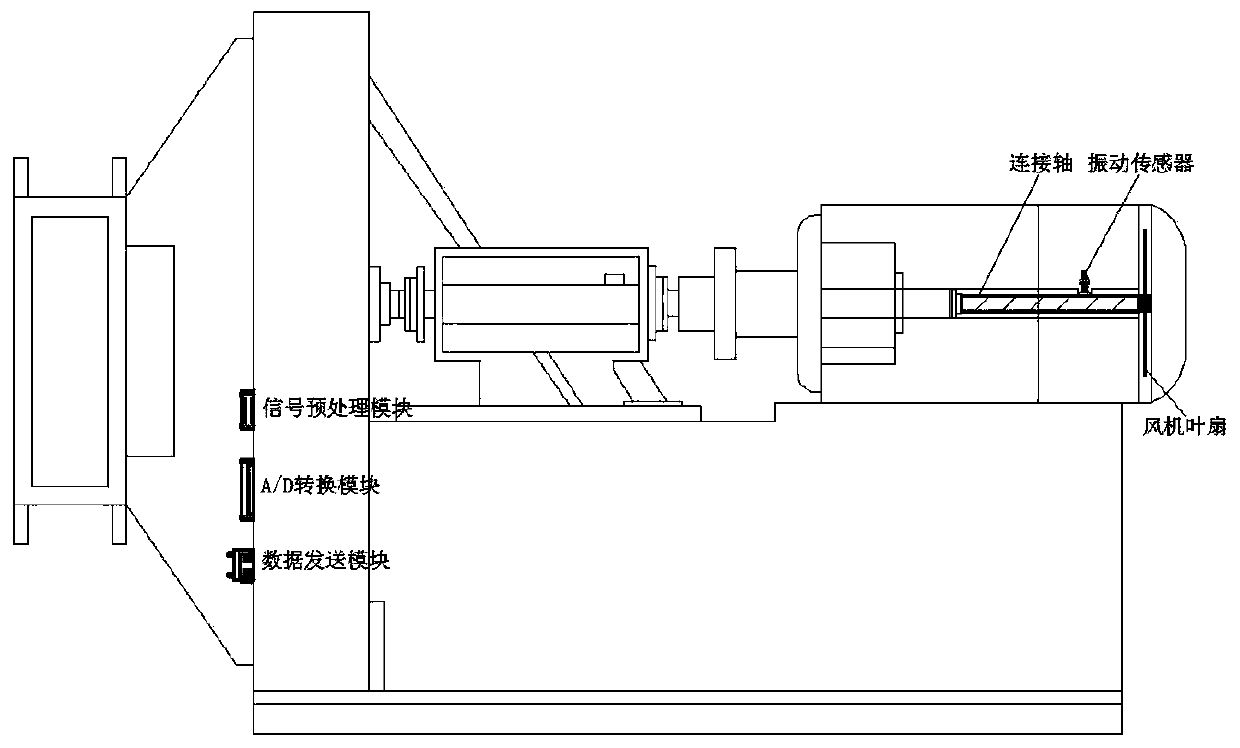

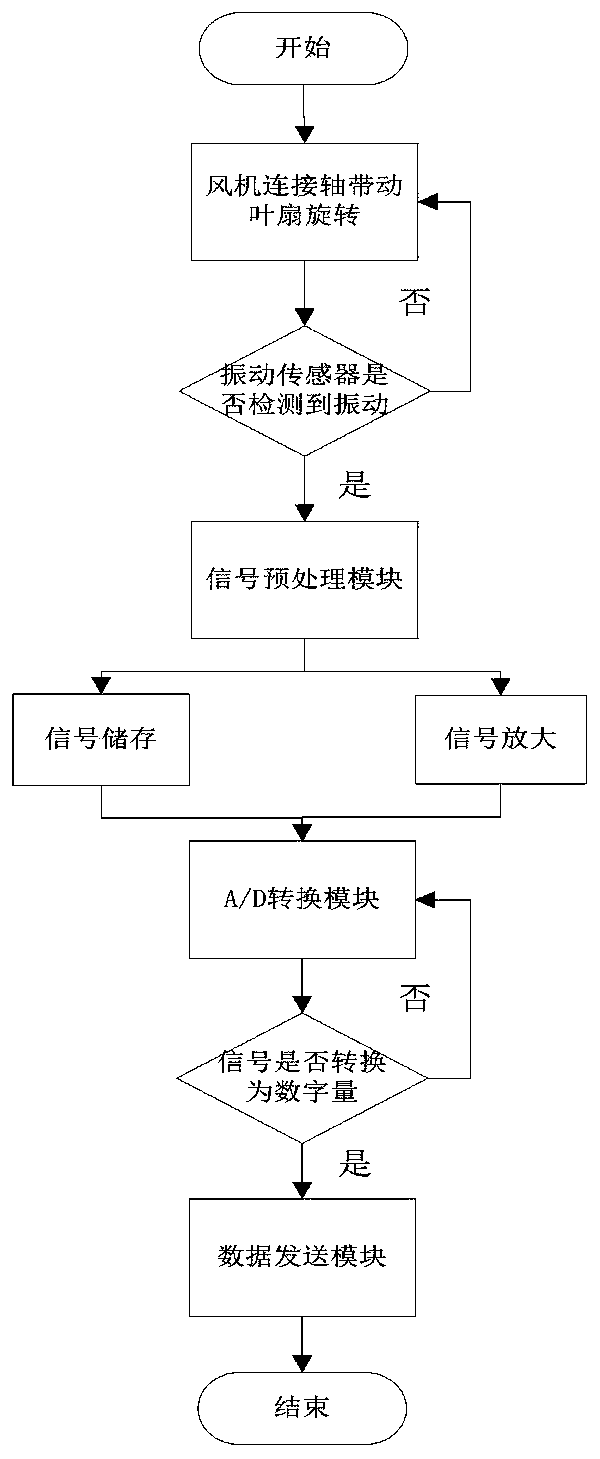

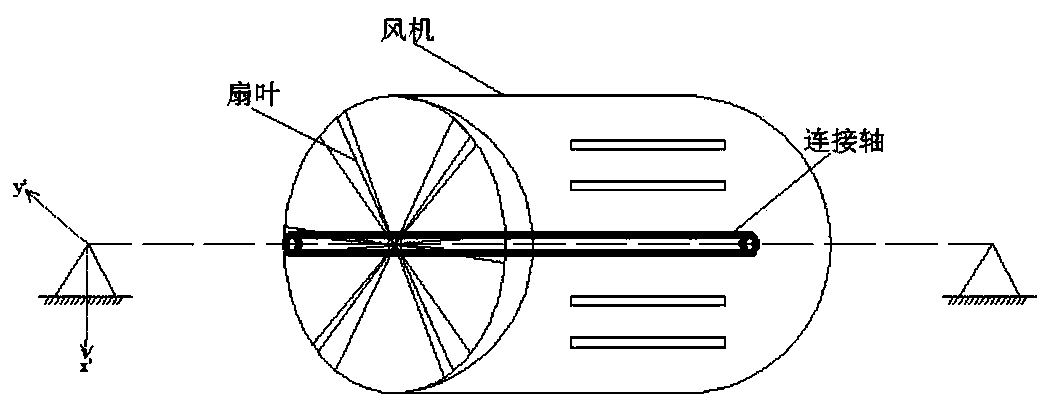

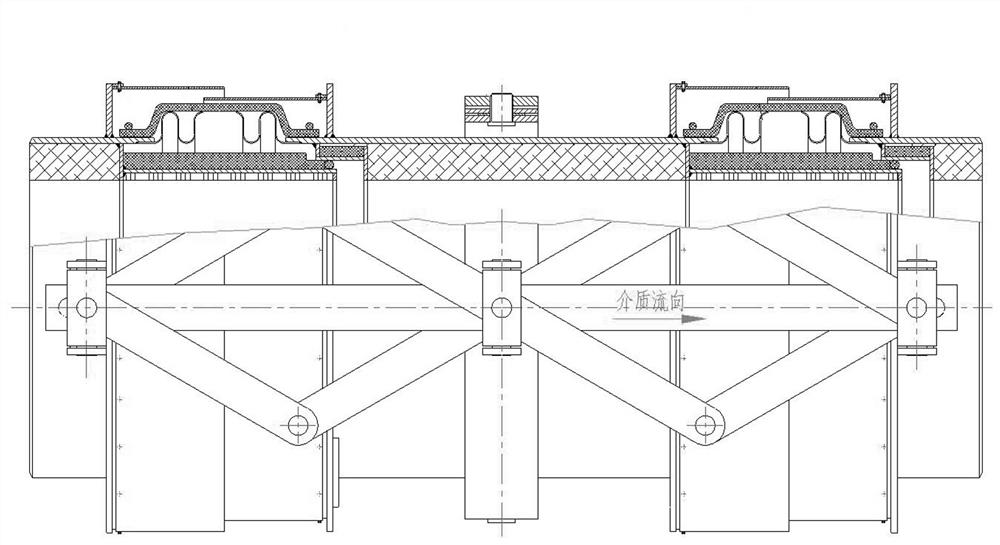

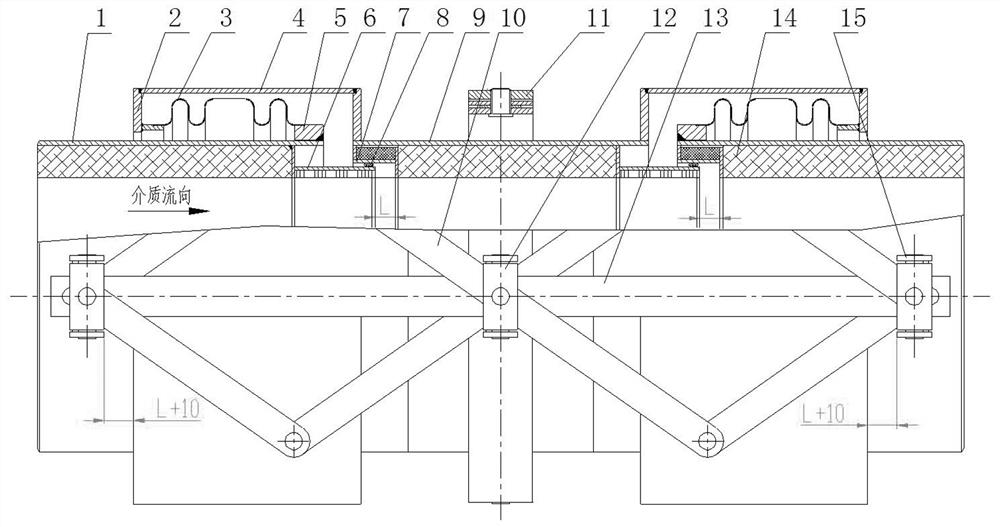

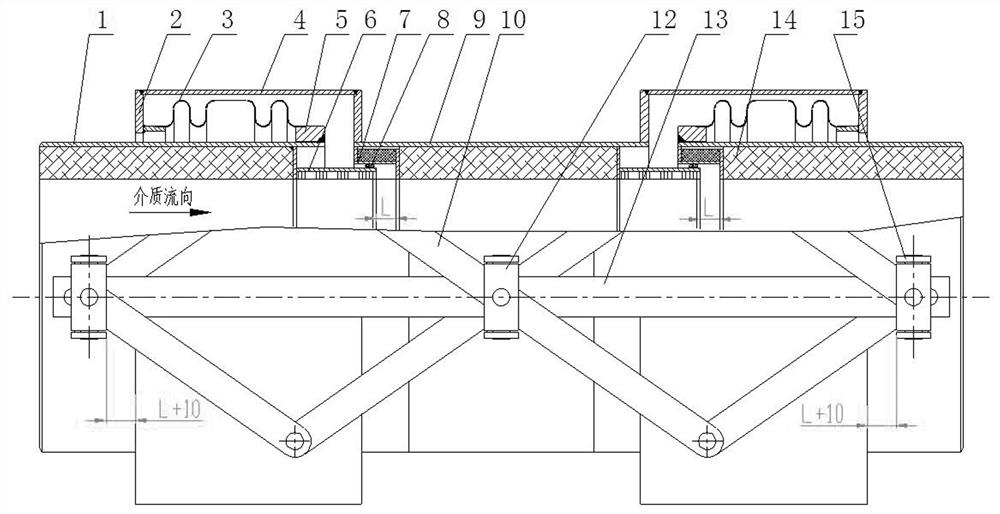

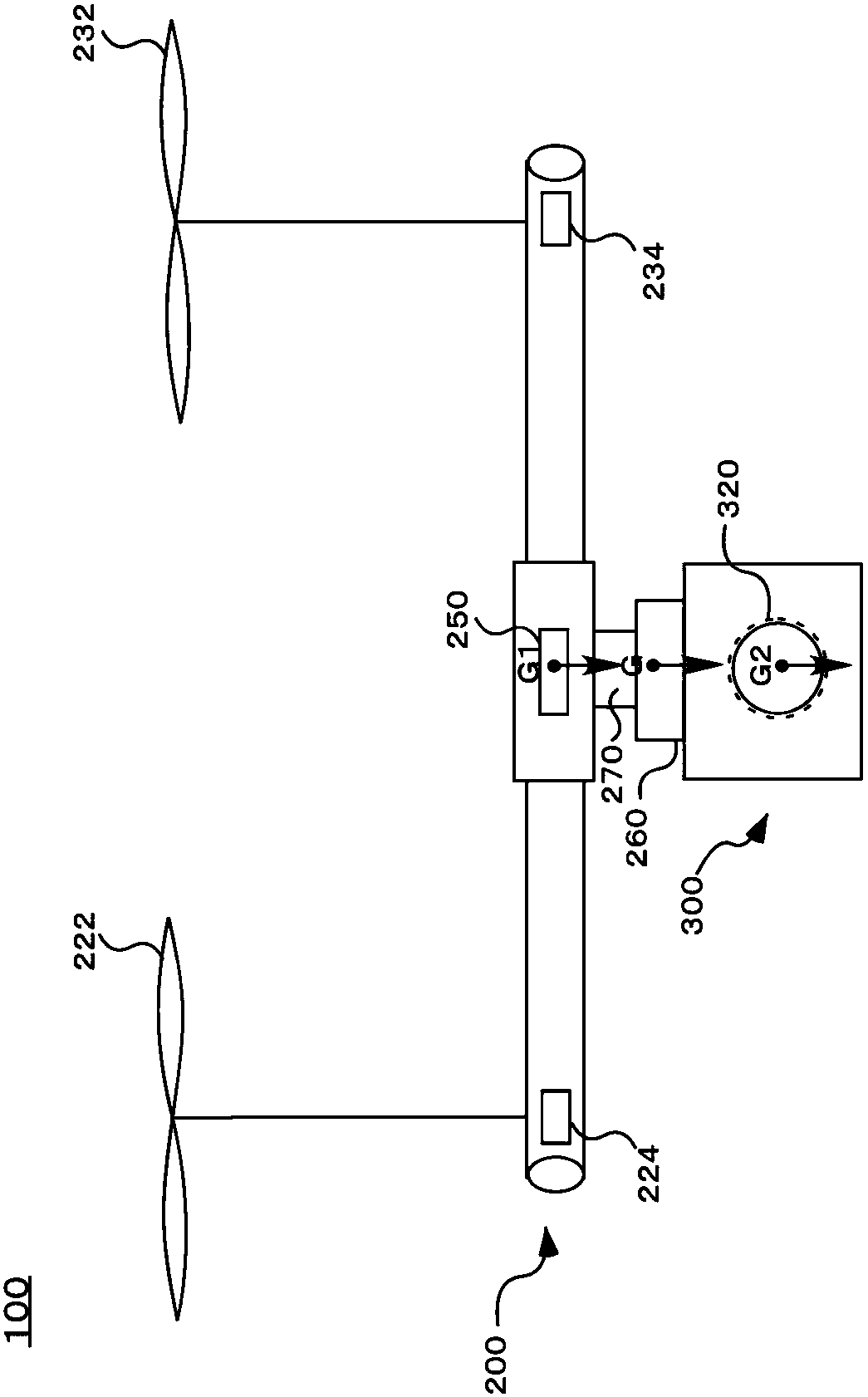

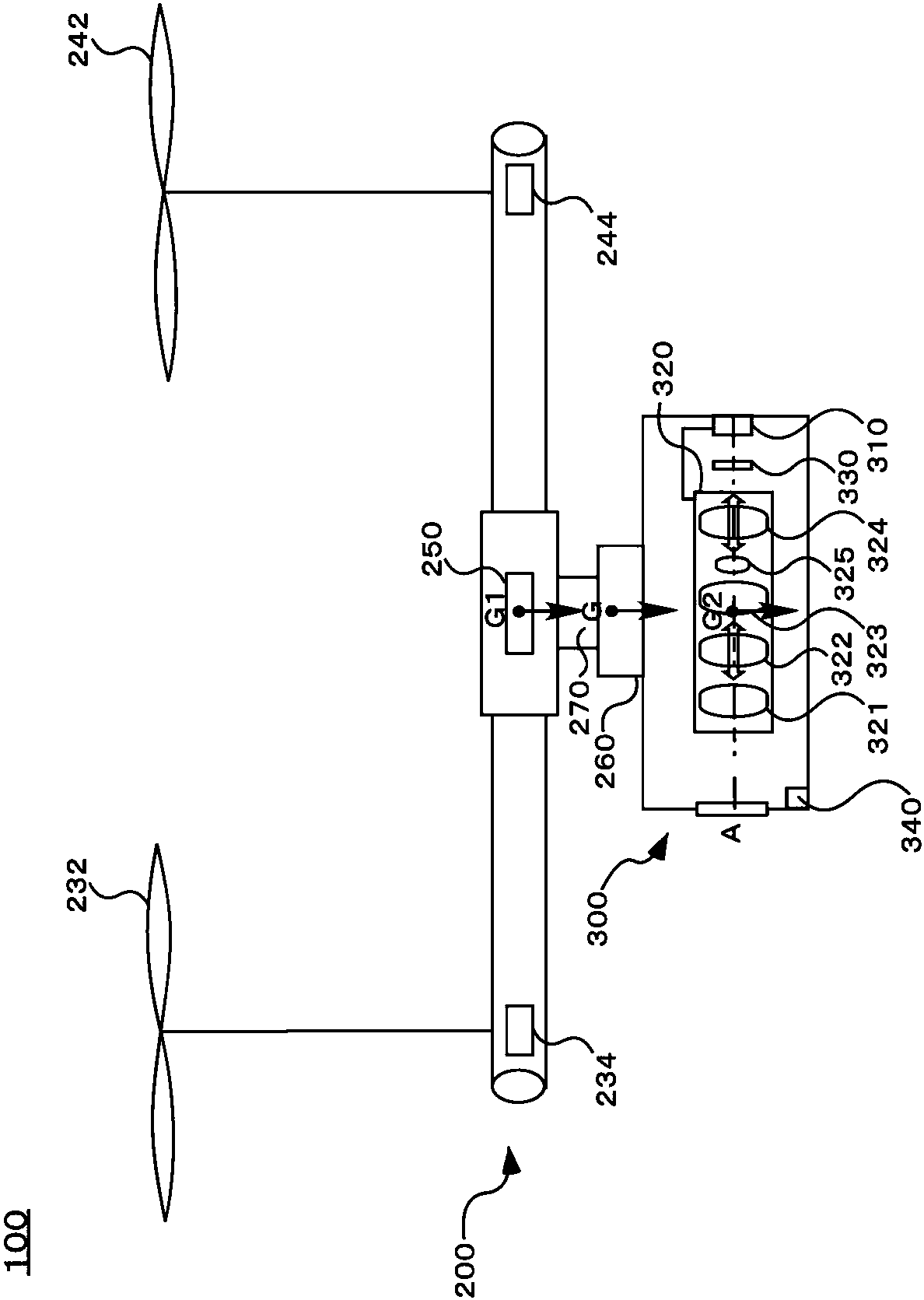

Blade vibration detection device and fault detection and prediction method for fan

ActiveCN109323853ASolving Compensation IssuesHigh sensitivityMachine part testingEngineeringPrediction system

The invention provides a blade vibration detection and fault prediction system for fan. The fan rotates in a circular motion centering on a connecting shaft at a certain rotating speed. The system comprises a fan blade vibration detecting device as a hardware part and a fan fault prediction method as a software part.

Owner:CHINA TOBACCO ZHEJIANG IND

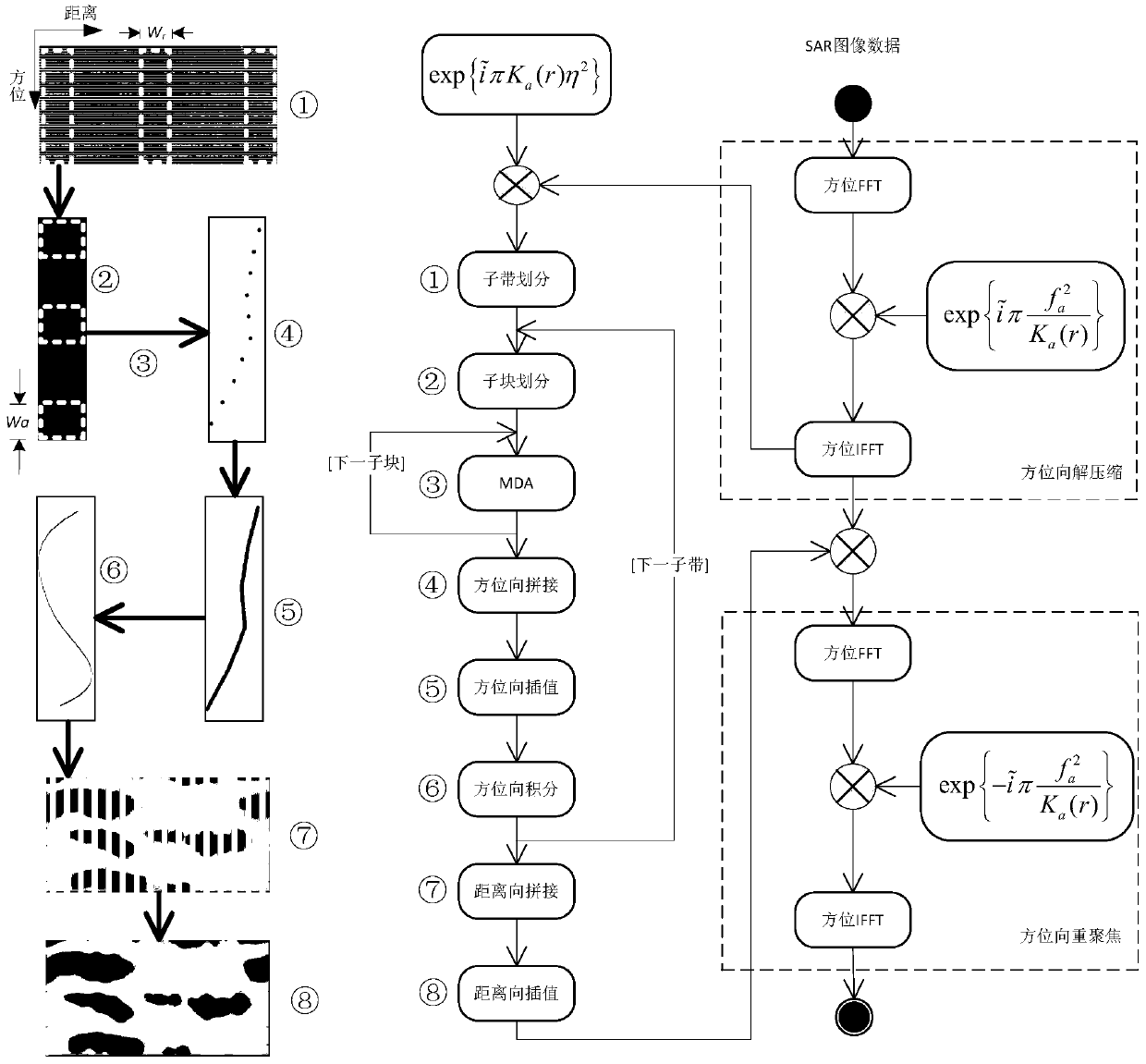

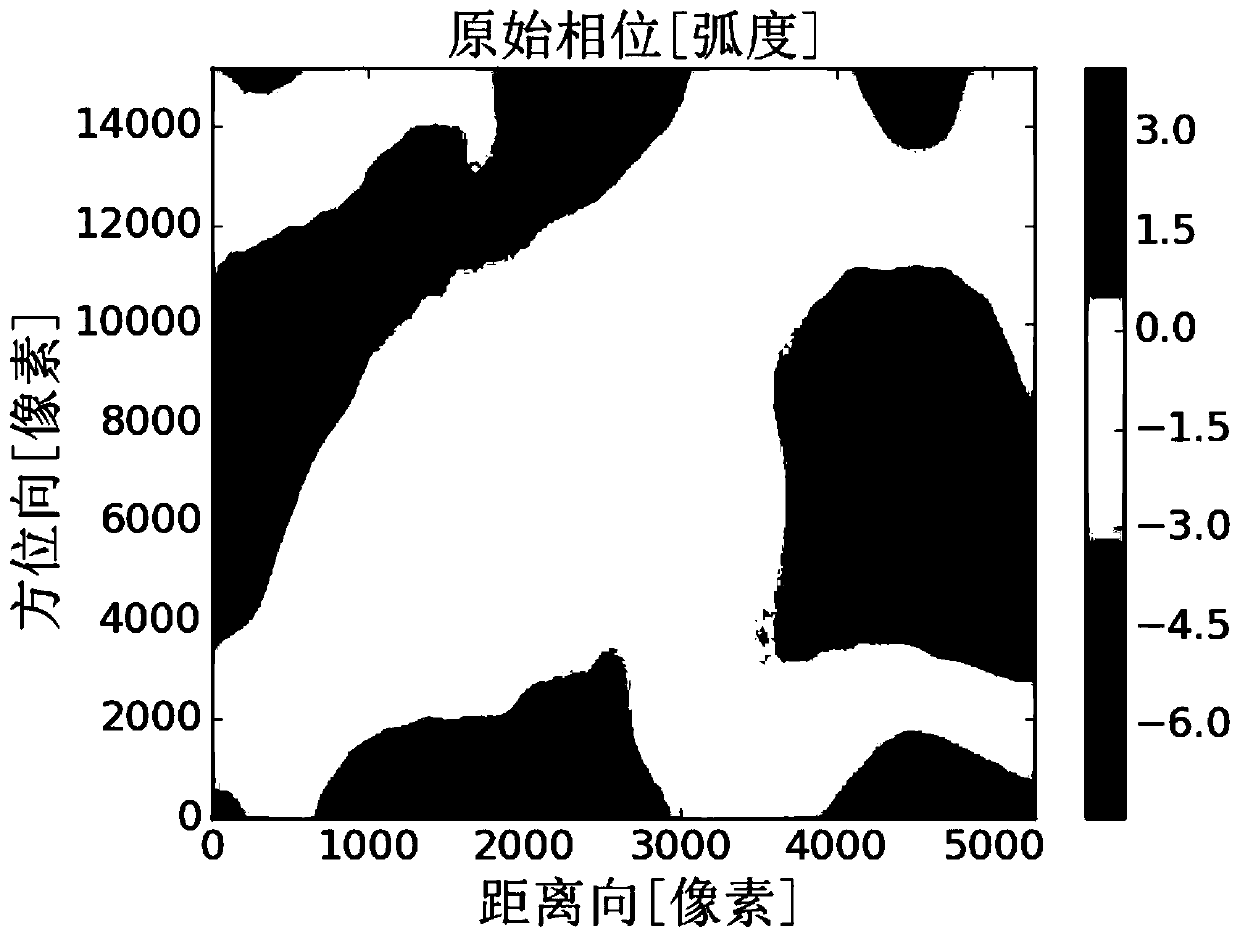

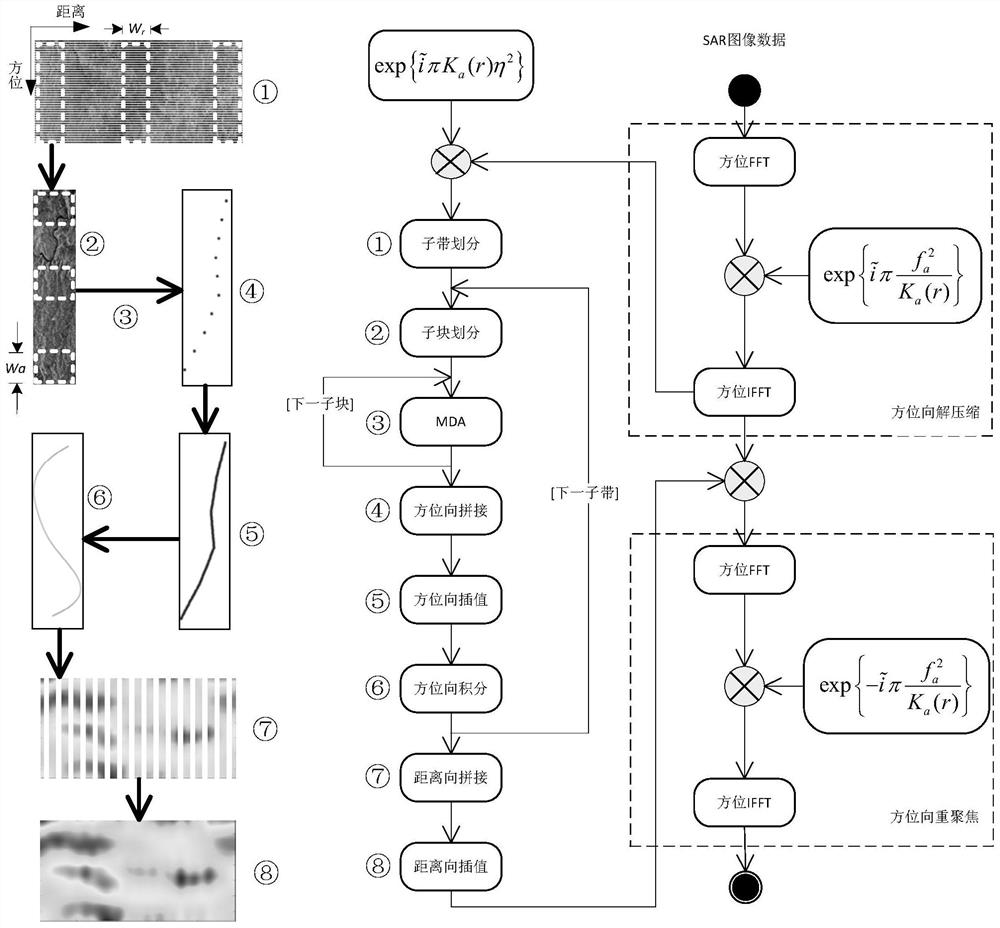

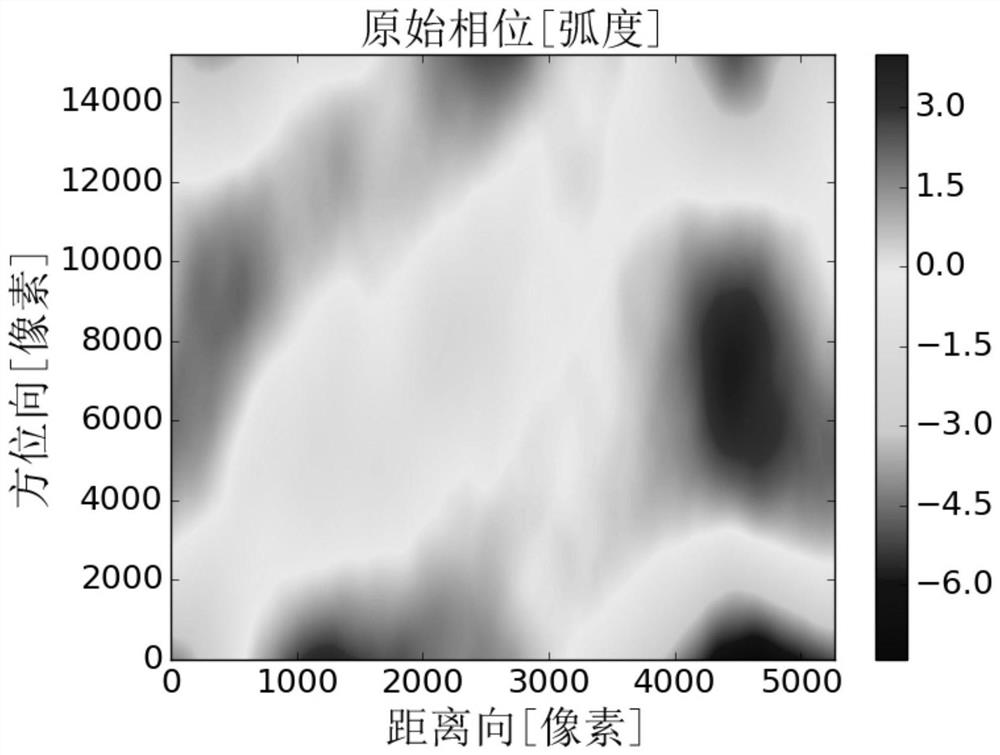

High-resolution spaceborne SAR imaging error estimation and compensation method

ActiveCN110261833ADelay error resolutionSolving Compensation IssuesRadio wave reradiation/reflectionTroposphereHigh definition

The invention provides a high-resolution spaceborne SAR imaging error estimation and compensation method aimed at a troposphere disturbing delay error. An obtained high-definition spaceborne SAR image is decompressed in the azimuth to obtain azimuth decompression data; deramping is carried out to obtain deramped azimuth decompression data; the data is divided into sub-band along the distance direction, and then divided to sub-blocks along the azimuth; an MDA algorithm is used to estimate an azimuth frequency modulated inclination error introduced for the troposphere disturbance delay error in each sub-block, and the troposphere disturbing delay error is estimated; the troposphere disturbing delay error is used to compensate the azimuth decompression data; and a result is re-focused in the azimuth to obtain an accurately focused high-definition spaceborne SAR image. The method of the invention can be widely applied to improve the quality of the high-definition SAR image and random error estimation and compensation.

Owner:NAT UNIV OF DEFENSE TECH

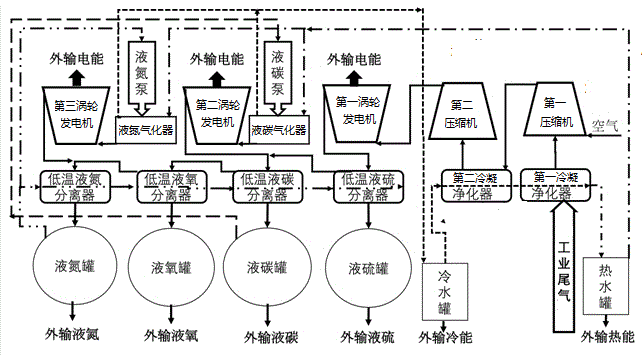

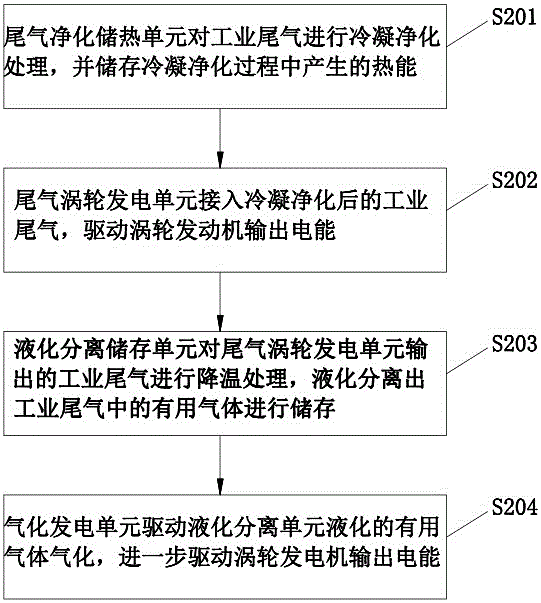

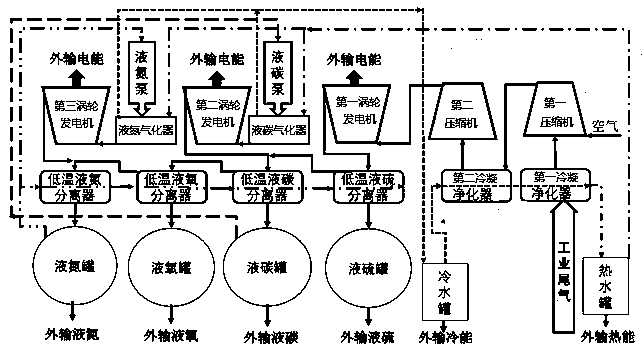

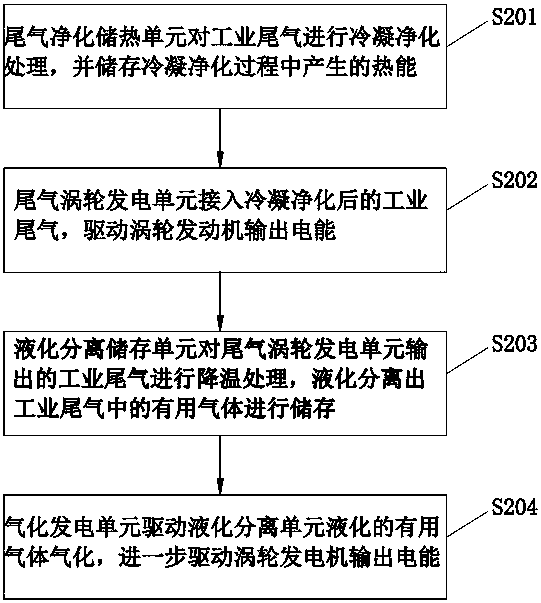

Industrial tail gas liquefaction energy storage power generation system and power generation method

The invention discloses an industrial tail gas liquefaction energy storage power generation system and a power generation method. The system is characterized in that industrial tail gas is subjected to condensation and purification through a tail gas purification heat storage unit; heat energy generated during the condensation and purification process is stored; electric energy is generated from condensed and purified tail gas through a tail gas turbine power generation unit; useful gases like sulfur, carbon, oxygen and nitrogen are liquefied and separated from tail gas output by the tail gas turbine power generation unit through a liquefaction separation storage unit; a pressurization gasification power generation unit drives liquefied useful gases of the liquefaction separation unit to be gasified, and electric energy is further generated; and thereby, industrial tail gas liquefaction, separation, storage and gasification power generation are achieved, the comprehensive utilization rate and emission reduction rate of industrial tail gas are increased, the energy compensation problem of peak regulating and valley filling is efficiently solved, investment of matching generating sets, power transmission and distribution facilities and gas supply networks for building energy storage power stations or peak regulating power stations is reduced, the remote power supply loss and running cost are reduced, and the safety, stability and economy of power supply and peak regulating are improved.

Owner:成都聚熵能源科技有限公司

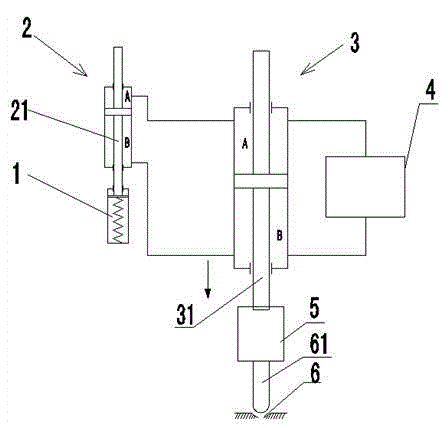

Overload electrohydraulic executing mechanism drive valve system with compensation function

ActiveCN104405711ASolve a spring-bound puzzleSolving Compensation IssuesOperating means/releasing devices for valvesServomotor componentsEngineeringMechanical engineering

The invention provides an overload electrohydraulic executing mechanism drive valve system with a compensation function, and aims to solve the problem that CN101709807 is constrained by a spring and thus cannot be applied to the overload electrohydraulic executing mechanism drive valve system. The key points are that the system comprises a drive oil cylinder, a compensation oil cylinder and a spring, wherein a piston rod of the drive oil cylinder is connected with a valve rod of an overload valve; a piston rod of the compensation oil cylinder is abutted against the spring; the compensation oil cylinder is connected with the drive oil cylinder in parallel. The system has the positive effects that energy is absorbed, stored and released by the spring and the compensation oil cylinder together, the spring is not a unique involved part, the problem of spring constraint is solved, further the application to the overload electrohydraulic executing mechanism drive valve system is realized, and reliable operation of the overload electrohydraulic executing mechanism drive valve system is guaranteed.

Owner:SHENYANG NORTHEAST ELECTRIC POWER CONTROL

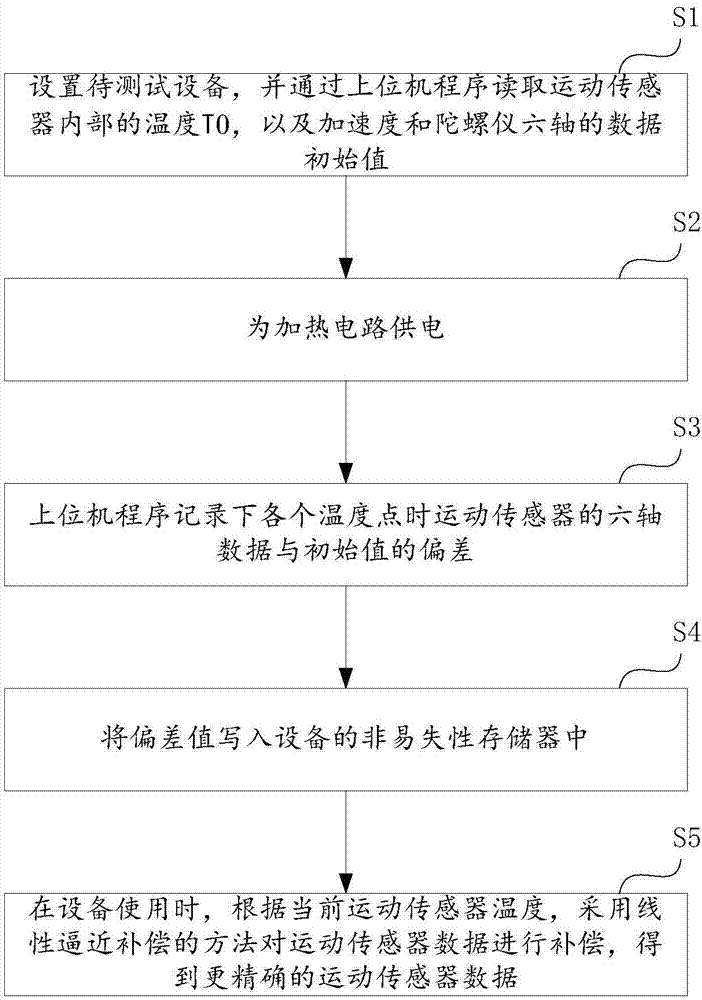

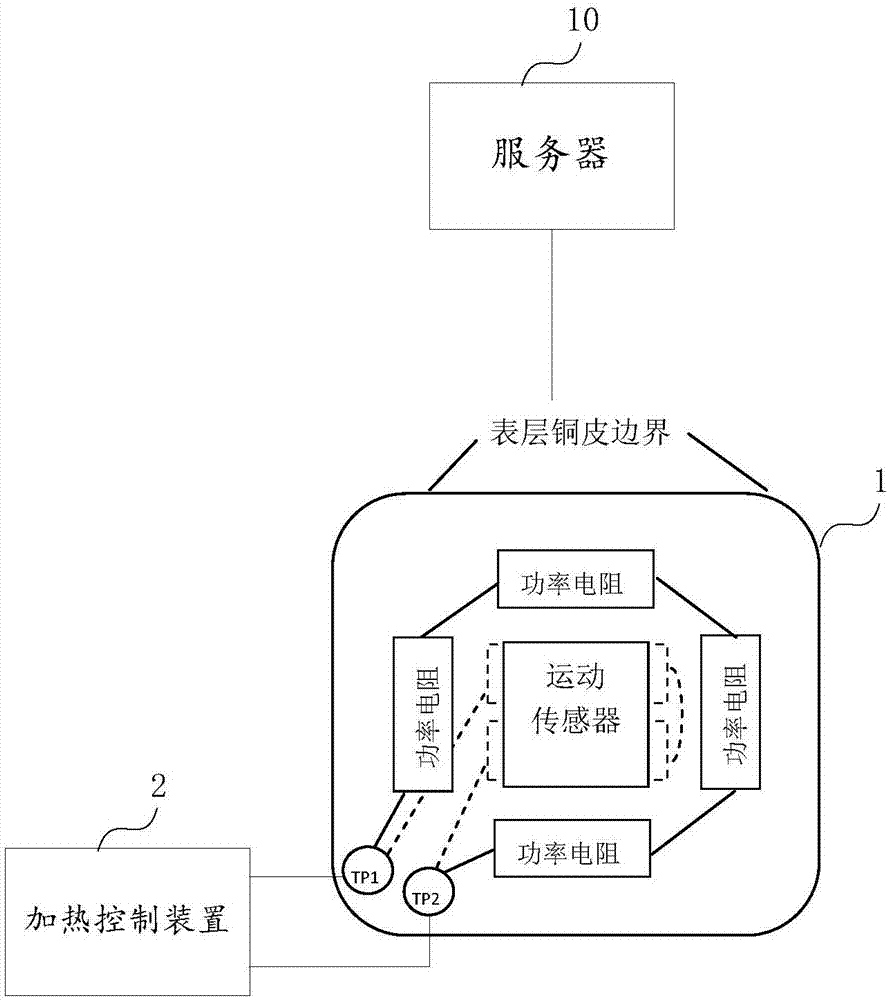

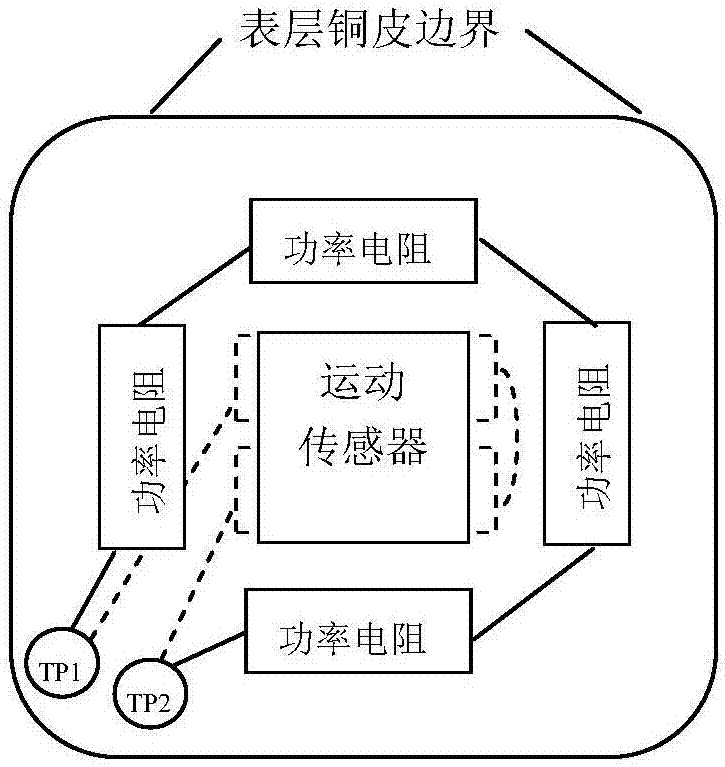

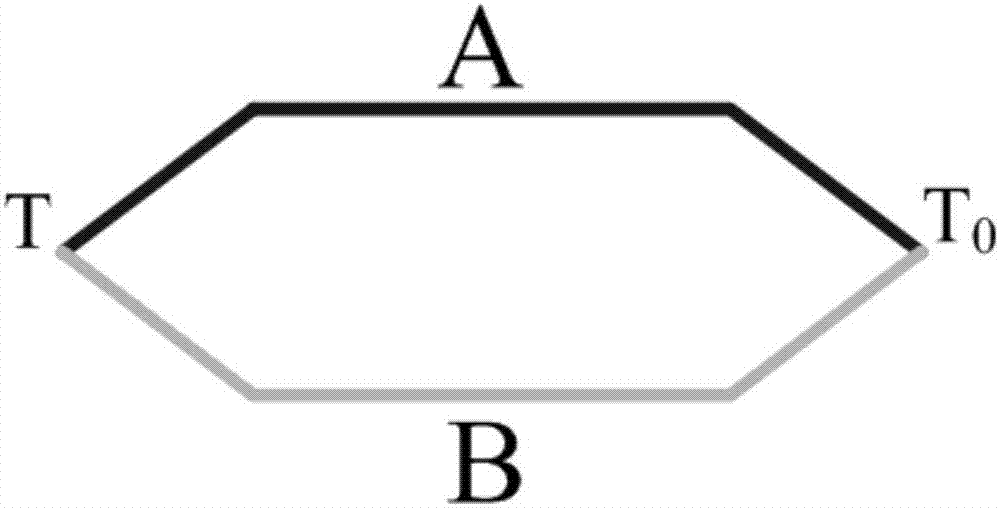

Motion sensor temperature drift correction method and system, and electronic device

ActiveCN107515013ASolve correctionSolving Compensation IssuesTesting/calibration of speed/acceleration/shock measurement devicesCorrection methodTest facility

The invention discloses a motion sensor temperature drift correction method and system, and an electronic device. The method comprises the steps: step S1, setting a device to be tested, and reading the temperature T0 inside a motion sensor, the acceleration speed and data initial values of six axes of a gyro by an upper computer program; step S2, supplying power to a heating circuit; step S3, recording bias of the six axis data of the motion sensor and the initial values at each temperature point by the upper computer program; step S4, writing the bias value in a memory of the device; and step S5, in the use of the device, according to the current motion sensor temperature, adopting a linear approximation compensation method to compensate the motion sensor data, and thus obtaining more accurate motion sensor data. The motion sensor temperature drift correction method and system provided by the invention can solve the problem of calibration and compensation of the temperature drift of the motion sensor, and have relatively high efficiency and relatively low cost.

Owner:SHANGHAI WINGTECH INFORMATION TECH CO LTD

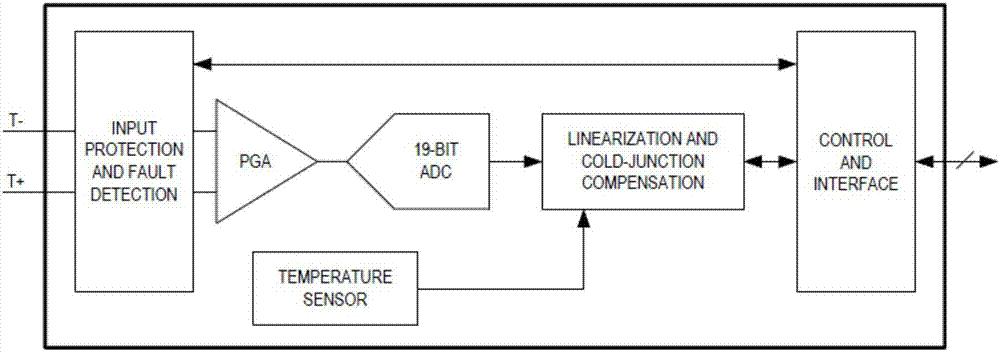

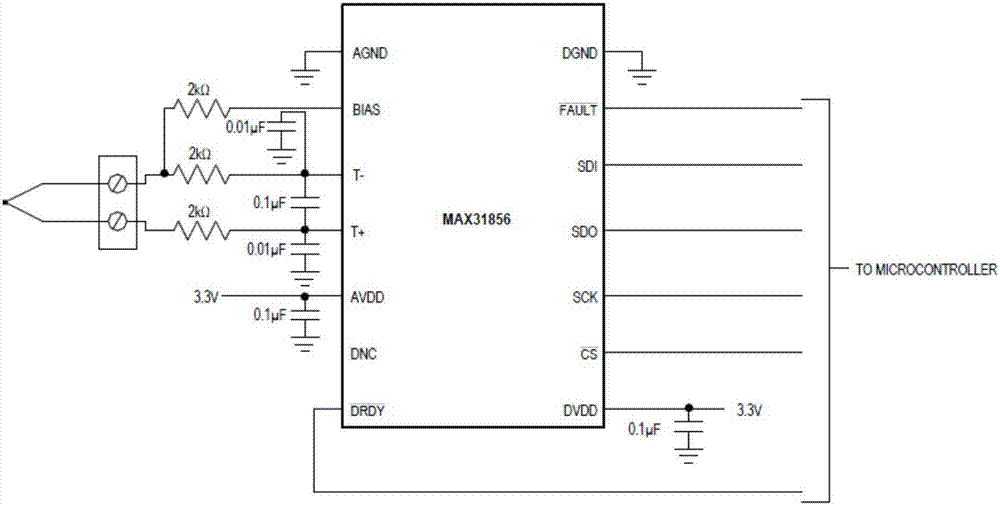

Thermocouple thermometer based on MAX31856 and test method

InactiveCN106885639ASolving Nonlinear Correction ProblemsConvenience to workThermometers using electric/magnetic elementsUsing electrical meansTemperature measurementThermometer

The invention relates to a thermocouple thermometer based on MAX31856 and a test method. The latest MAX31856 from Maxim is used as a thermocouple digital converter. The MAX31856 has a built-in 19-bit analog / digital converter (ADC). The MAX31856 is provided with an internal temperature sensor, and has a function of thermocouple cold-end automatic compensation. The MAX31856 is internally provided with a temperature query table supporting thermocouples of different index numbers, and thermocouple temperature data can be corrected nonlinearly through the temperature query table. The problem on how to realize thermocouple cold-end compensation and the problem on how to correct thermocouple temperature measurement nonlinearly are solved. The temperature resolution of the thermometer is 0.0078125 DEG C. The accuracy of thermocouple voltage measurement is up to + / -0.15%. The thermometer is portable, can be connected with a computer to display data in real time, greatly facilitates the work of engineering technicians, and has certain practical value.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

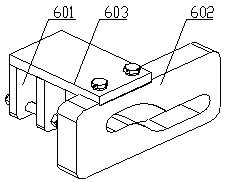

Locking and turning device for suspension type air rail turnout interface

PendingCN108569299ASolving Compensation IssuesSolve the timing difference problemRope railwaysLinear motionExpansion joint

The invention relates to a locking and turning device for a suspension type air rail turnout interface which can fundamentally solve the problem of locking and switching an interface for suspension type air rail turnouts and meets the need for a vehicle to change lines. A power output end of an electric push rod is hinged on one end of a locking pin and drives a cam mechanism to perform linear motion; the cam mechanism drives crank mechanisms to perform rotation having a sequential difference with the locking pin; a hinge four-bar mechanism comprises the crank mechanisms, connecting rod members and turning crank components; and the crank mechanisms drive horizontal locking pins and overturn plates to rotate through the connecting rod members and the turnover mechanism components, thereby realizing horizontal locking of the locking pins and overturn of the horizontal locking pins and the overturn plates. The locking and turning device has the advantages of solving the problem of compensation for a reserved expansion joint of suspension type translation turnouts and the problem of interface locking after switching is in place, so as to realize the continuity of a running surface of avehicle, and achieving the driving of the locking and turning movement through the same power source by adoption of the hinge four-bar mechanism, reducing power supply and improving the reliability of the device.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Volume-type fluid mechanism

InactiveCN104863848AExtend your lifeImprove sealingEngine of arcuate-engagement typeEngine of intermeshing engagement typeDrive shaftMoving parts

Owner:ZEROQ SCI & TECH

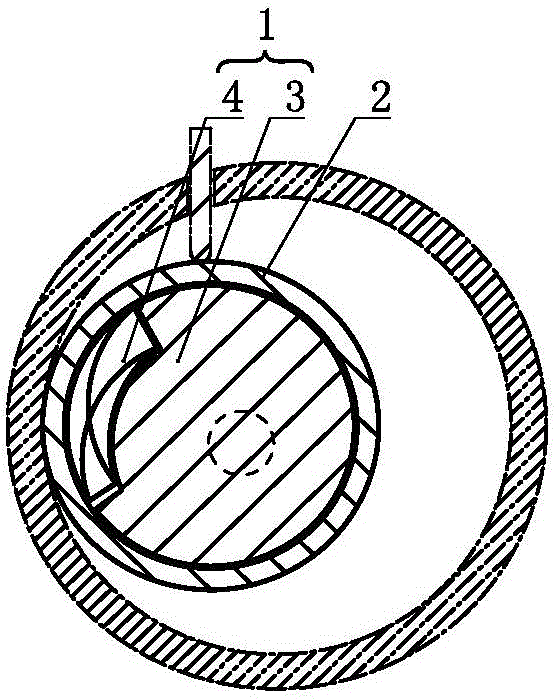

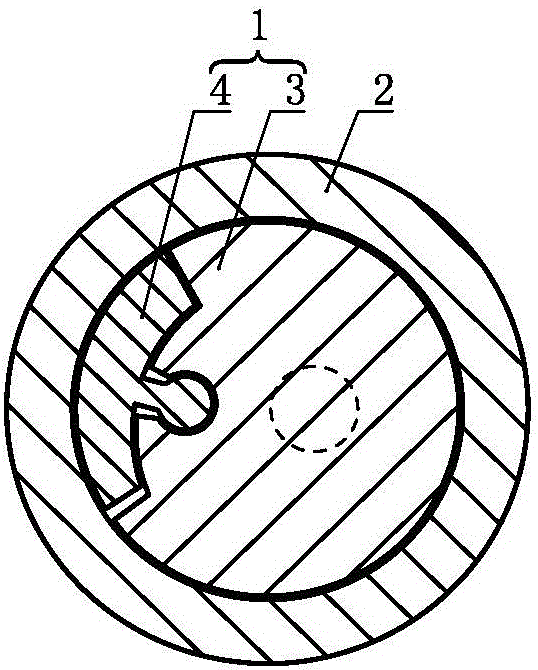

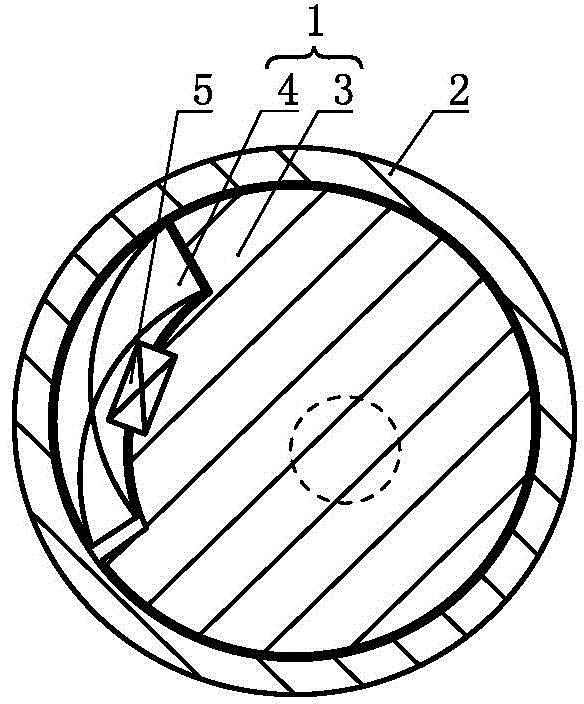

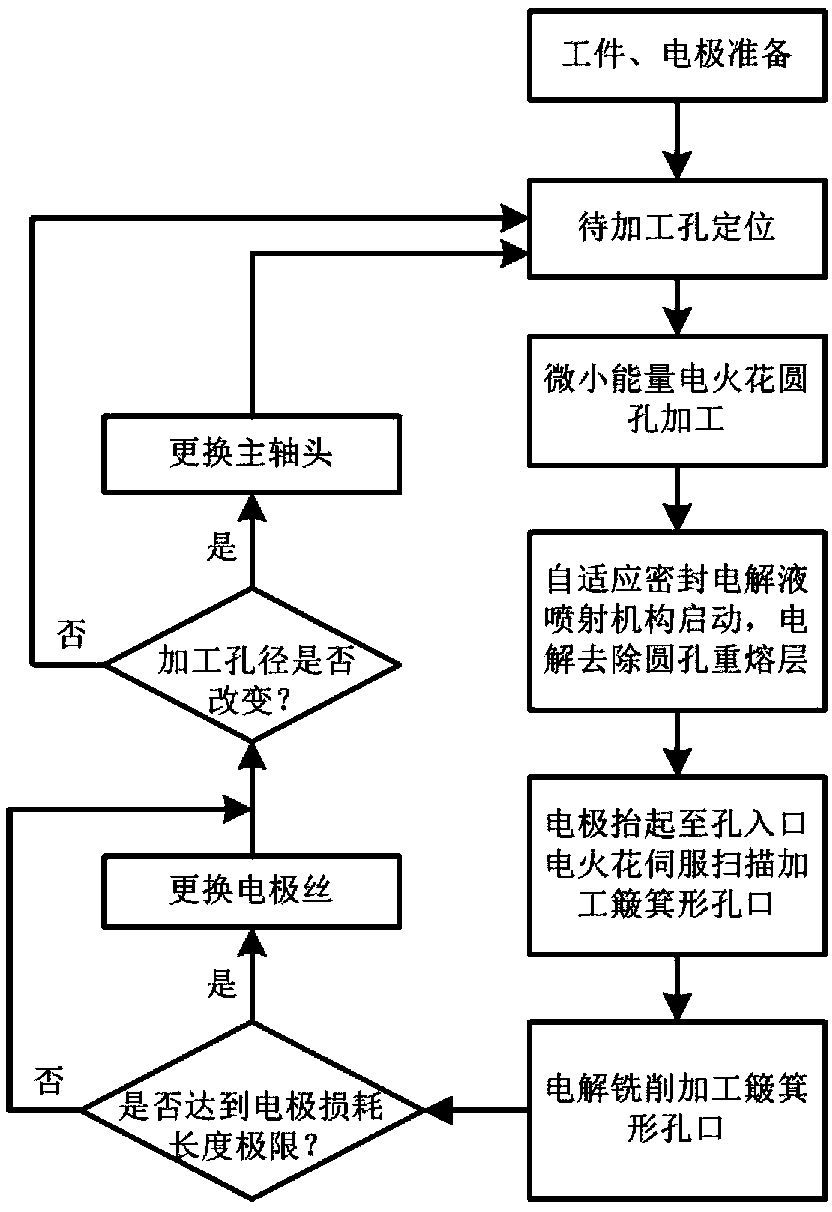

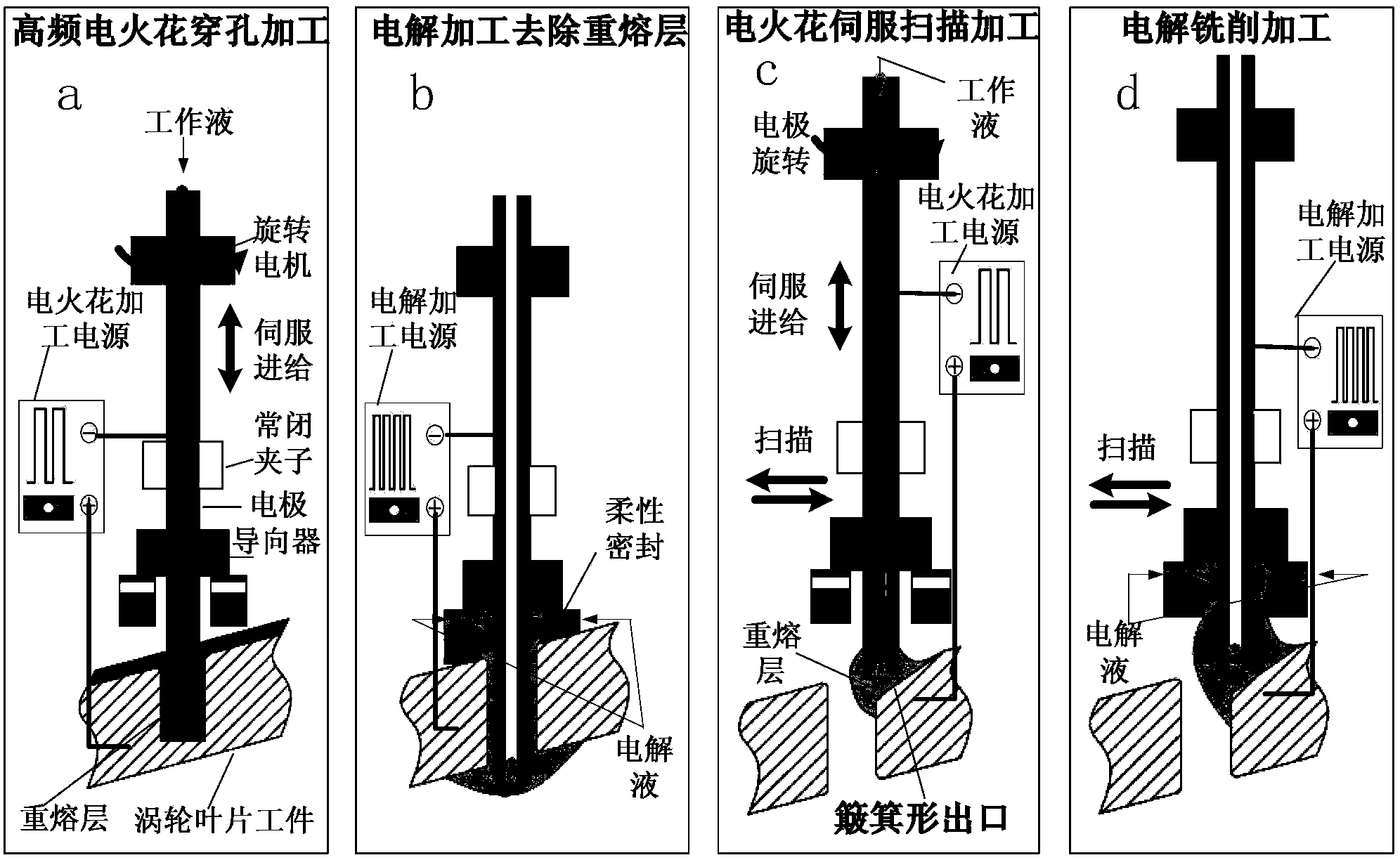

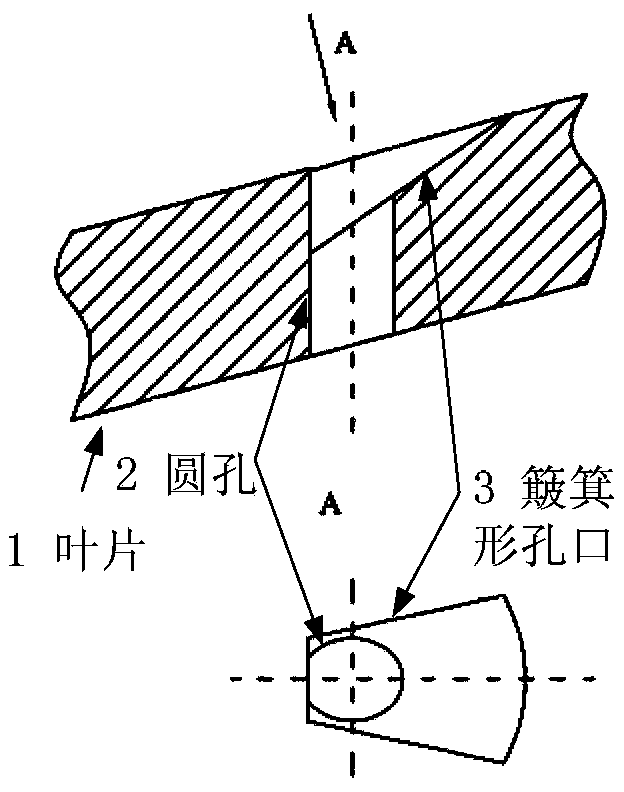

Machining method of gravity-free smelting layer air membrane hole of aviation engine turbine blade

InactiveCN102861956BReduce manufacturing difficultyShorten the manufacturing cycleAviationEngineering

The invention belongs to the technical field of small hole electric machining and particularly relates to a machining method of a gravity-free smelting layer air membrane hole of an aviation engine turbine blade. The machining method comprises four steps: firstly, machine a circular hole with a needed size a nickel-based high-temperature alloy blade on a gas turbine by utilizing washing liquid electric sparks in a hollow electrode according to a design requirement; then utilizing the same electrode to electrolyze the machined circular hole in an electrolyte environment of an outer washing solution to remove a re-smelted layer; then, raising the electrode and utilizing an electric spark servo scanning and milling and machining process to machine a dustpan-shaped hole opening of the air membrane hole; and finally, utilizing the end part of the electrode to carry out electrolytic milling machining on the dustpan-shaped hole opening to remove the re-smelted layer of the hole opening so as to improve the surface quality. According to the machining method disclosed by the invention, the problem of a residual re-smelted layer and small cracks of the air membrane hole machined by the electric sparks can be solved, a secondary clamping and positioning error is avoided and the machining efficiency is improved.

Owner:TSINGHUA UNIV

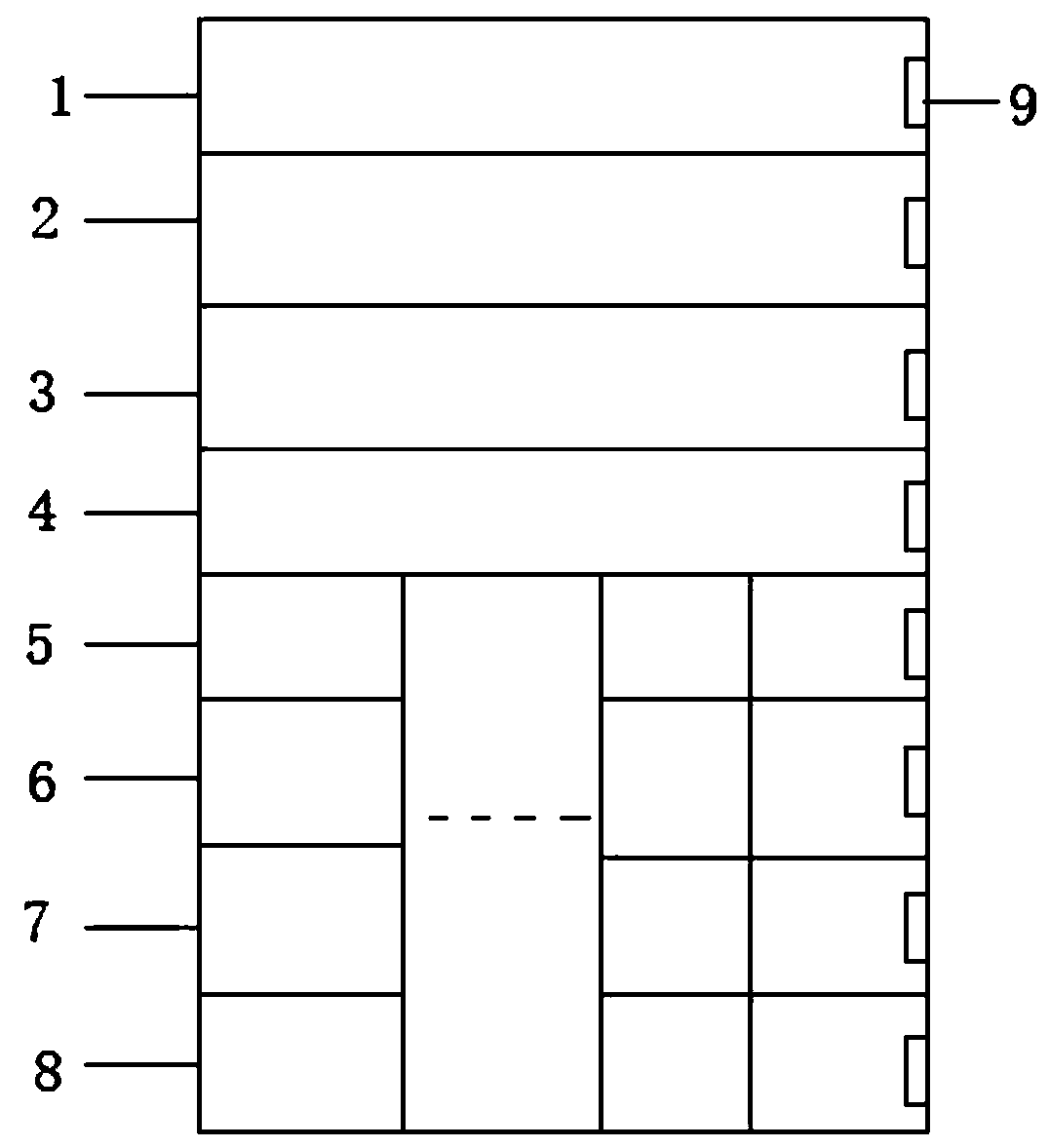

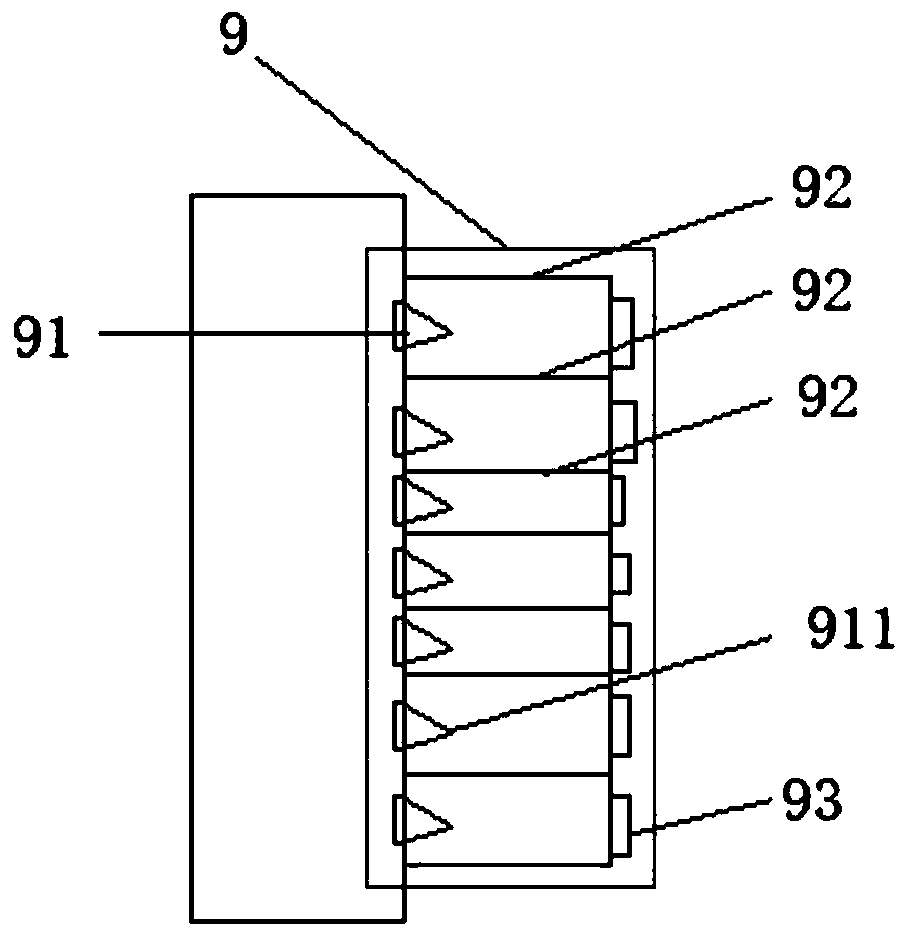

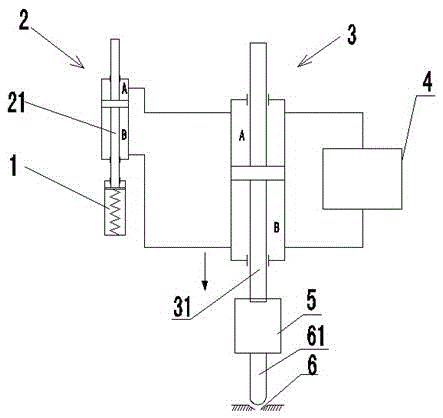

Dual-control dynamic compensation transformer

PendingCN111355245AMeet the special requirements of reactive power compensation controlMeet the requirements of special situations in different sitesTransformers/inductances coolingTransformers/inductances casingsPower compensationProgrammable logic controller

The invention provides a dual-control dynamic compensation transformer, which comprises a transformer shell and a transformer main body (1), and is characterized by further comprising an intelligent reactive compensation acquisition control unit (2), a PLC (Programmable Logic Controller) (3), a main protection switch (4), a plurality of dynamic compensation loops and ion radiators (9) uniformly arranged on the inner wall of the transformer shell. And the dynamic compensation loop comprises a fuse (5), a reactor group (6), a compensation capacitor (7) and a filter (8) which are connected in sequence. According to the application, the phase-controlled reactor and the PLC are added into the dynamic reactive power compensation circuit, so that the special requirements of different customers onreactive power compensation control can be better met, and the protection function and the switching function of the reactive power compensation controller are more fully applied.

Owner:NANTONG HAIWANG ELECTRIC

Aeromagnetic Compensation Method Based on Nonlinear Aeromagnetic Total Field Gradient Compensation Model

ActiveCN106959471BSolving Compensation IssuesHigh precisionElectric/magnetic detectionAcoustic wave reradiationStatistical physicsCharacteristic matrix

The invention provides an aeromagnetic compensation method based on a non-linear aeromagnetic total field gradient compensation model. Time series weighting modeling of output of a flux-gate magnetometer is carried out, and a direction cosine of a geomagnetic field and a direction cosine of an airplane, and an aeromagnetic compensation model characteristic matrix are estimated, and thereafter airplane platform magnetic interferences observed by an optical pump magnetometer is predicted to acquire the non-linear aeromagnetic total field gradient compensation model, and then the non-linear aeromagnetic total field gradient compensation model is solved to acquire an aeromagnetic compensation result. By establishing the non-linear aeromagnetic total field gradient compensation model, a compensation problem of an interference magnetic field caused by time delay between data channels is effectively solved, and the precision of the aeromagnetic compensation is greatly improved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Latitude Unknown Self-alignment Method of Strapdown Inertial Navigation System under Dynamic Interference Conditions

ActiveCN106123921BGuaranteed accuracyGuaranteed validityNavigation by speed/acceleration measurementsInertial coordinate systemInertial navigation system

Owner:BEIJING UNIV OF TECH

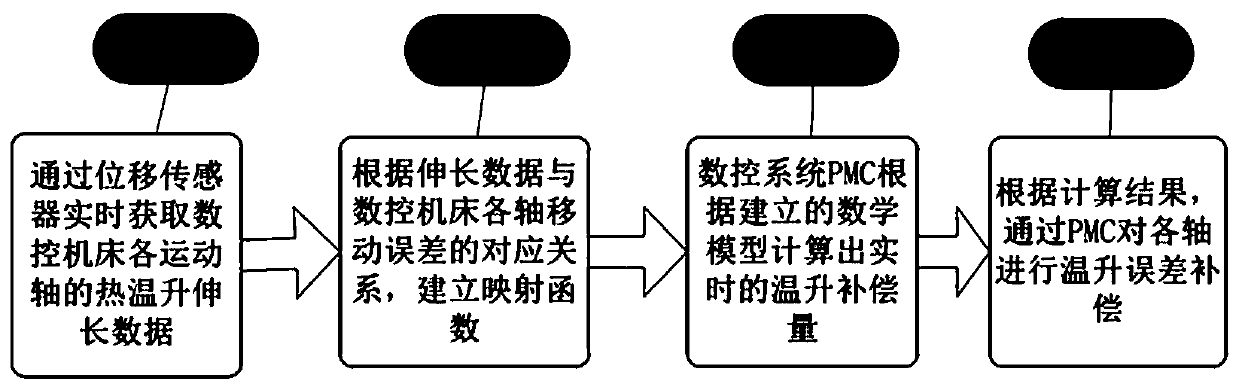

Thermal temperature rise compensating method for numerical-control machine tool

InactiveCN111230570ACorrect positioning accuracySolve measurementMeasurement/indication equipmentsMaintainance and safety accessoriesControl systemMachine tool control

The invention discloses a thermal temperature rise compensating method for a numerical-control machine tool. In work of the numerical-control machine tool, a displacement sensor obtains elongation ofa rolling ball lead screw under each motion axis thermal temperature rise state of the numerical-control machine tool, and a corresponding mapping function is established according to a relationship between the elongation and a motion axis displacement error value; and a PMC system of a numerical-control system automatically calculates the error compensation value of each motion axis, and the numerical-control machine tool control system compensates motion axis displacement errors caused by thermal temperature rise. According to the thermal temperature rise compensating method disclosed by theinvention, the elongation of each motion axis lead screw thermal temperature rise is directly obtained by the displacement sensor, so that elongation data errors of rolling ball lead screw temperature rise are small, and precision is high; elongation data of the rolling ball lead screw temperature rise and the motion axis displacement error data are transmitted into the PMC of the numerical-control system to automatically calculate the error compensation value, and therefore, thermal temperature rise compensation precision is effectively improved, and product cost increase amount is smaller than 2%-3%. The method realizes solving the problems that processing precision of numerical-control equipment is reduced, a qualification rate of processed products is low, and the like as motion axispositioning errors are caused by motion axis transmission shaft deformation due to temperature changes with low cost.

Owner:广州义同机械实业有限公司

An industrial tail gas liquefaction energy storage power generation system and power generation method

Owner:成都聚熵能源科技有限公司

High-resolution Spaceborne SAR Imaging Error Estimation and Compensation Method

ActiveCN110261833BDelay error resolutionSolving Compensation IssuesRadio wave reradiation/reflectionPattern recognitionTroposphere

The invention provides a high-resolution spaceborne SAR imaging error estimation and compensation method aimed at a troposphere disturbing delay error. An obtained high-definition spaceborne SAR image is decompressed in the azimuth to obtain azimuth decompression data; deramping is carried out to obtain deramped azimuth decompression data; the data is divided into sub-band along the distance direction, and then divided to sub-blocks along the azimuth; an MDA algorithm is used to estimate an azimuth frequency modulated inclination error introduced for the troposphere disturbance delay error in each sub-block, and the troposphere disturbing delay error is estimated; the troposphere disturbing delay error is used to compensate the azimuth decompression data; and a result is re-focused in the azimuth to obtain an accurately focused high-definition spaceborne SAR image. The method of the invention can be widely applied to improve the quality of the high-definition SAR image and random error estimation and compensation.

Owner:NAT UNIV OF DEFENSE TECH

Current detection circuit and current loop control circuit including the current detection circuit

ActiveCN104300792BHigh precisionReduce power consumptionEfficient power electronics conversionCurrent/voltage measurementCurrent loop controlCMOS

The invention relates to the field of CMOS integrated circuit design, in particular to a current detection circuit and a current loop control circuit including the current detection circuit. By setting a parallel MOS tube current detection circuit and a series resistance current detection circuit, the accuracy of current detection can be improved. At the same time, the power consumption of the circuit is reduced, and the use of the adaptive slope compensation circuit can further avoid the problem of overcompensation, and the detection signal and compensation signal in this circuit can be directly added, which is convenient for the design of the current mode DC-DC circuit .

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

A fan blade vibration detection device and fault detection and prediction method

ActiveCN109323853BSolving Compensation IssuesHigh sensitivityMachine part testingPredictive methodsFan blade

The invention provides a blade vibration detection and fault prediction system for fan. The fan rotates in a circular motion centering on a connecting shaft at a certain rotating speed. The system comprises a fan blade vibration detecting device as a hardware part and a fan fault prediction method as a software part.

Owner:CHINA TOBACCO ZHEJIANG IND

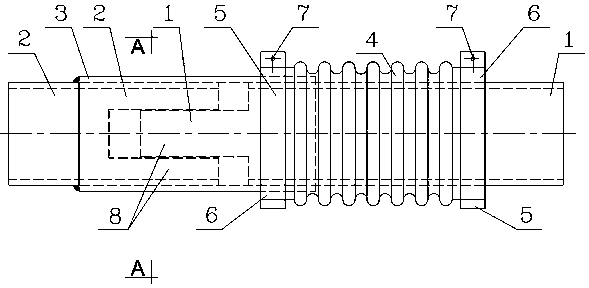

Compound expansion joint used in petrochemical field

PendingCN111664307AEnsure safetySolving Corrosion Failure ProblemsPipeline expansion-compensationPipe heating/coolingThermal insulationPetrochemical

The invention provides a compound expansion joint used in the petrochemical field. The compound expansion joint used in the petrochemical field is provided with an intermediate pipe assembly. Heat insulation linings are arranged on the inner wall of the intermediate pipe assembly, and two ends of the intermediate pipe assembly are separately connected to a set of external pressing corrugated pipeassemblies arranged back to back. The external pressing corrugated pipe assemblies comprise end pipes, corrugated pipes, corrugated pipe connection pipes, end ring assemblies, outer pipes, retaining ring assemblies with thermal insulation ceramic fibers, flow-guiding barrel assemblies with wear-resistant linings and dust-proof sealing rings, the corrugated pipes sleeves the end pipes, the heat insulation linings are arranged on the inner walls of the end pipes, one ends of the corrugated pipes are fixedly connected with the ends, close to the direction of an expansion center, of the end pipesthrough the corrugated pipe connection pipes, the other ends of the corrugated pipes are connected with one ends of the outer pipes through end ring assemblies sleeving the end pipes and having gaps with the end pipes, and the other ends of the outer pipes are connected to the intermediate pipe assembly. The compound expansion joint can completely solve the problem of corrosion failure of a cold wall pipeline high temperature expansion joint of a large refining and chemical plant, and the cost of expansion joint is reduced.

Owner:中船双瑞(洛阳)特种装备股份有限公司

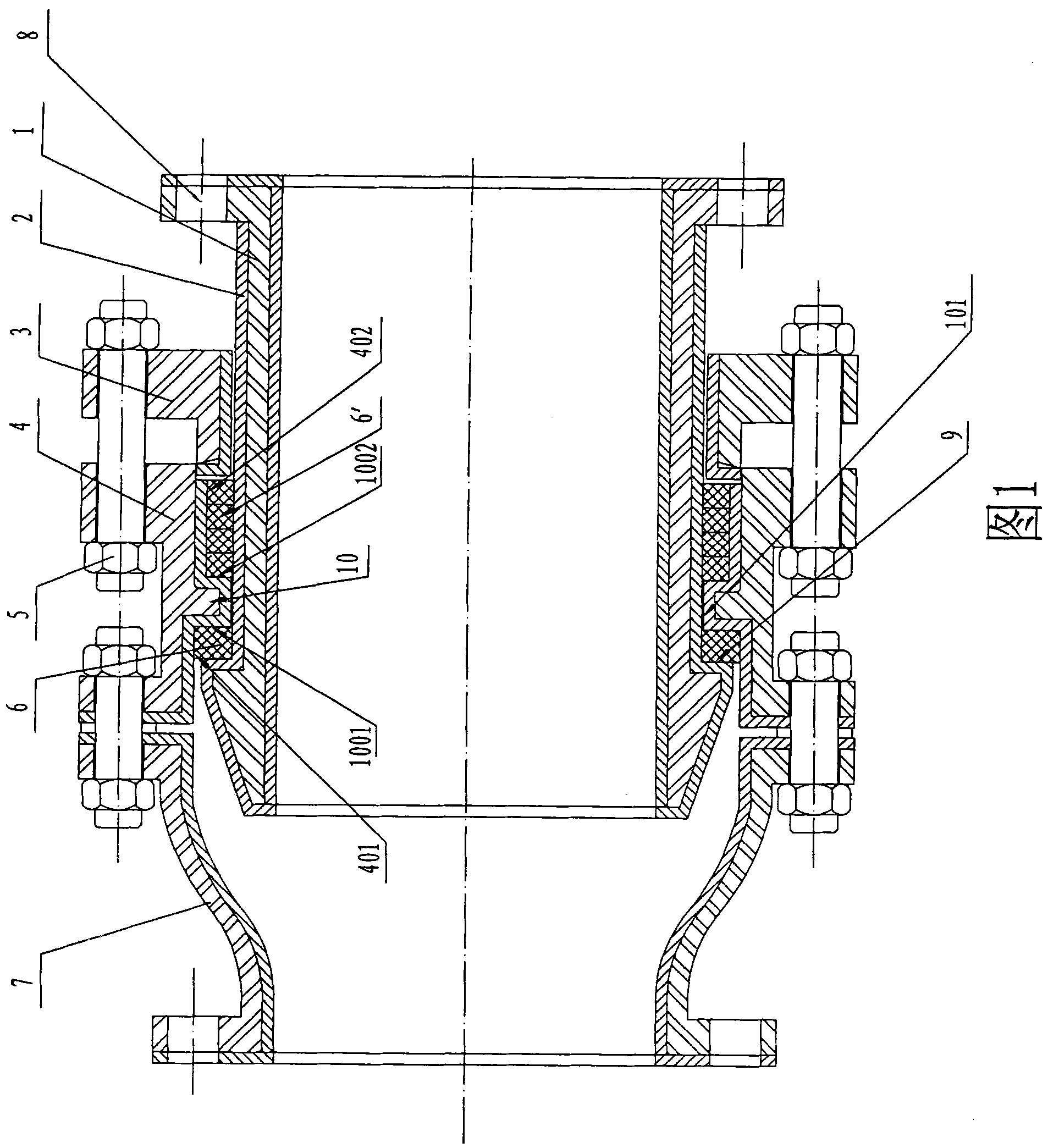

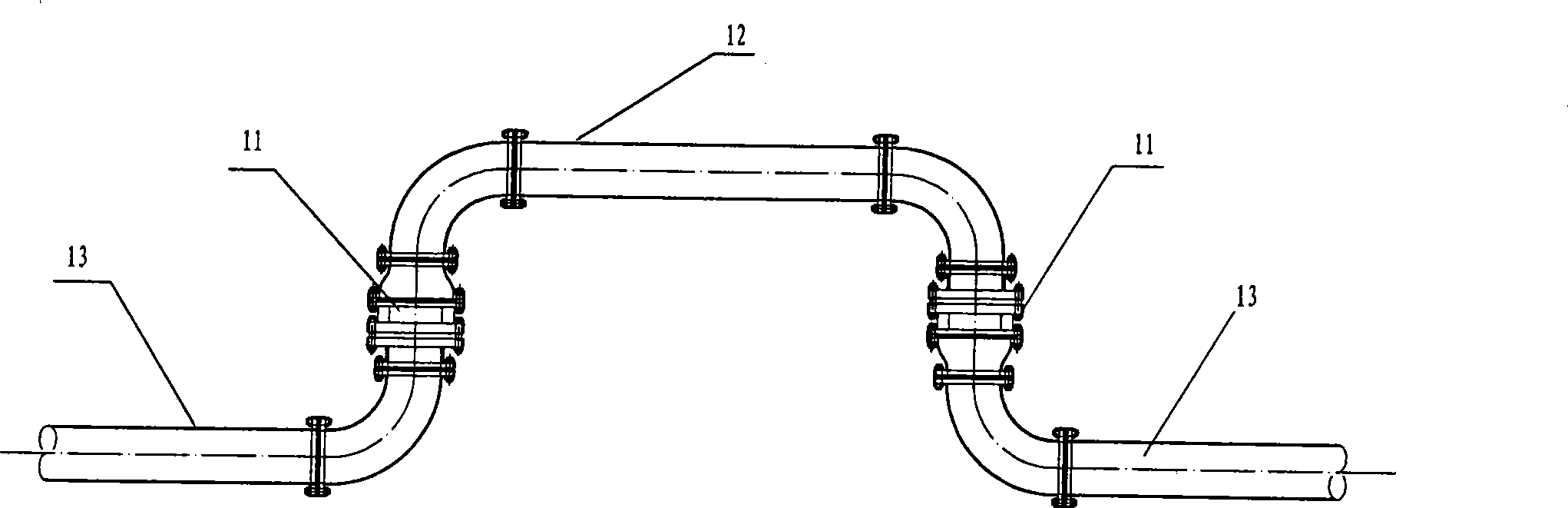

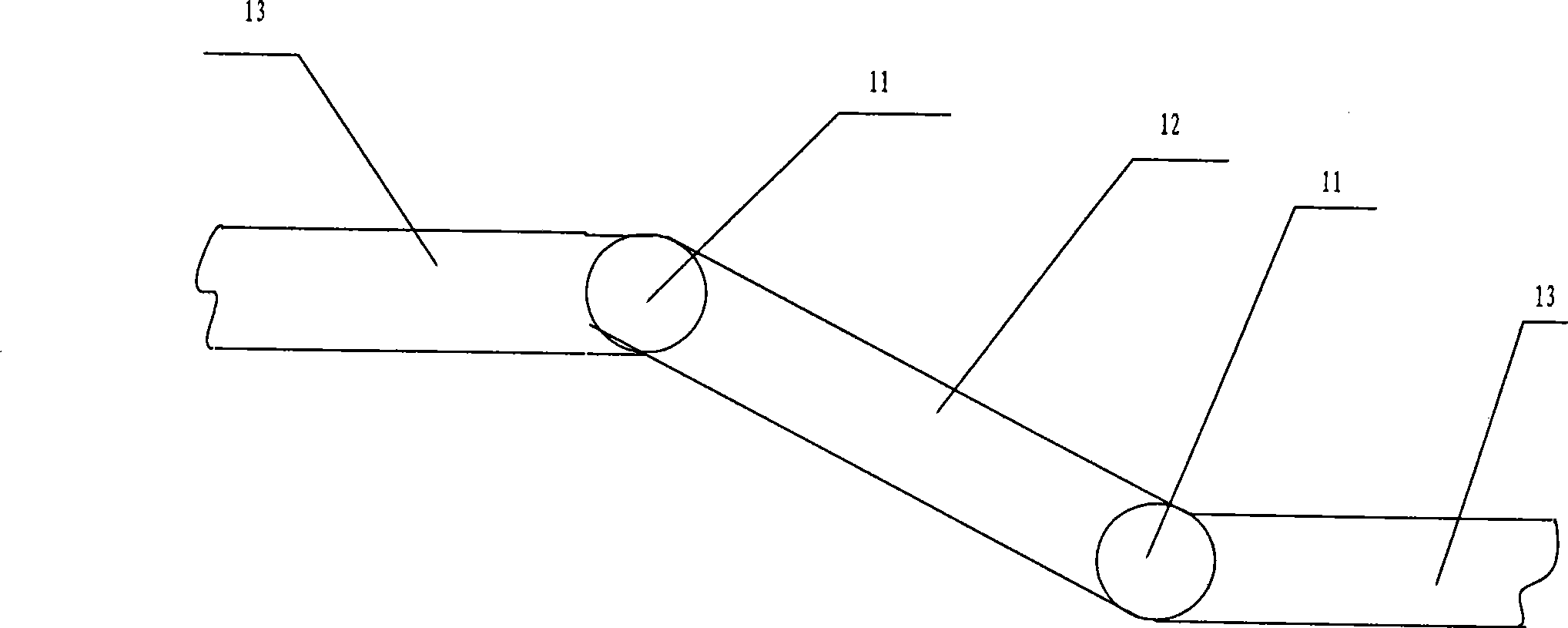

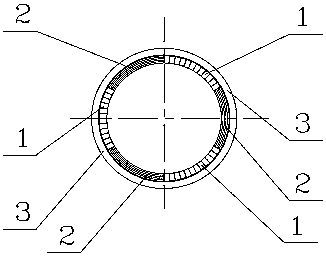

Rotating compensator for corrosion resistant pipeline and preparation method and compensating system

ActiveCN101338845BSolving Compensation IssuesExtended maintenance cyclePipeline expansion-compensationAdjustable jointsEngineeringHigh pressure

The invention discloses a rotary compensator used for anti-corrosion piping and a system thereof. The rotary compensator comprises a rotary connecting pipe (1), a sealing gland (3), a sealing seat (4) and a conical connecting pipe (7). The invention is characterized in that one end of the rotary connecting pipe (1) is welded with a coupling flange (8), the other end thereof is equipped with a terrace (9) and is inserted into a taper connecting pipe (7). The sealing seat (4) is covered on the rotary connecting pipe (1), the internal surface of the sealing seat (4) is equipped with an internal convex ring (10), one side of one end surface (1001) of the internal convex ring (10) is equipped with a high pressure resistant sealing gasket (6), and the side of the other end surface (1002) of theinternal convex ring (10) is equipped with a low pressure sealing gasket (6'), the flange end of the sealing gland (3) is inserted into the sealing space of the ring surface and touches against the sealing gasket (6'), and the sealing gland (3) and the sealing seat (4), the sealing seat (4) and the taper connecting pipe (7) are all connected via the flange connection structure. The compensation system comprises at least two compensators. The rotary compensator has the advantages of long service life, good pressure resistance and large compensation rate.

Owner:宋章根

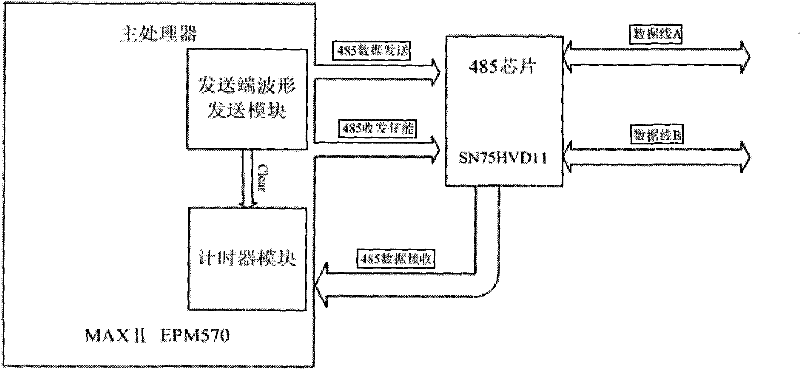

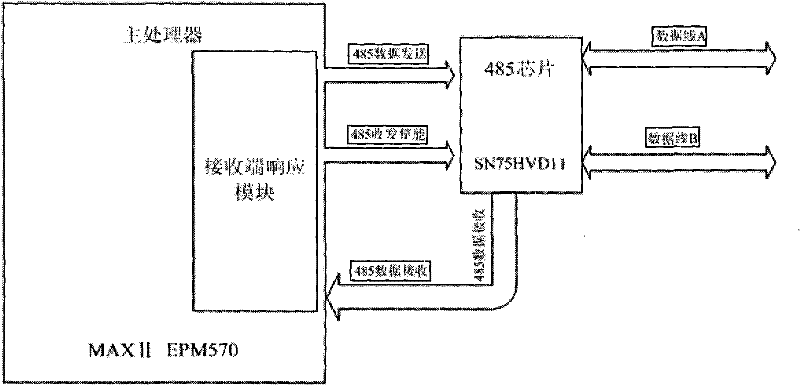

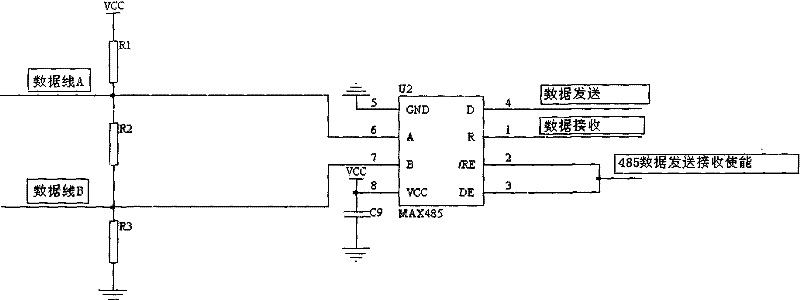

System and method for measuring length of twisted pair based on RS485 bus signal transmission delay

InactiveCN101949681BSolving Compensation IssuesAchieve the effect of digital solutionUsing electrical meansUsing reradiationComputer moduleEngineering

The invention relates to a system and a system for measuring the length of a twisted pair, which is the system and the method for measuring the length of the twisted pair based on RS485 bus signal transmission delay, comprising a transmission end and a receiving end. The transmission end comprises a transmission end main processor and a 485 chip, the transmission end main processor is communicated with the 485 chip, and the 485 chip is connected with the twisted pair; the transmission end main processor comprises a waveform transmission module and a timer module; the receiving end comprises areceiving end main processor and a 485 chip, the receiving end main processor is communicated with the 485 chip, and the 485 chip is connected with the twisted pair; and the receiving end main processor comprises a receiving end responding module. The invention adopts RS-485 signals as the measuring signal, the RS-485 adopts a way of balance transmission and differential receiving to realize the communication, the receiving end receives the transmission end data to respond the data, and the timer counts the whole process time, thereby calculating the length of the twisted pair.

Owner:DATCENT TECH

Method for compensating and enhancing dynamic shielded image in real time

InactiveCN101551901BQuality improvementReliable estimateImage enhancementImage analysisTime domainMotion vector

The invention provides a method for compensating and enhancing a dynamic shielded image in real time, solves the real-time compensation and enhancement problems of the dynamic shielded image and improves the quality of the dynamic shielded image. The technical proposal comprises the steps of estimating the motion vector between two adjacent images by a moderate method based on a video image outputby a camera, combining motion compensation with a time domain Kalman filter technique of a pixel gray value, performing time domain filtering treatment for all pixels so as to compensate the image information of a dynamic shielded area, and finally performing self-adaptive grey widening and edge enhancement treatments for the compensated image.

Owner:NAT UNIV OF DEFENSE TECH

Multifunctional compensator

InactiveCN108799679AEasy to moveNo damagePipeline expansion-compensationEngineeringThermal expansion

The invention relates to a multifunctional compensator which is specifically applied to a pipeline system of conveying solids / liquids and gas, and in particular relates to a compensating device for solving thermal expansion of a pipeline. The multifunctional compensator comprises a pipeline which is composed of three pipe conduits which can move freely axially, wherein a bushing is arranged out ofthe pipeline to control the moving tracks of the two movable pipelines, and sealing structures are arranged among the pipe conduits. The compensator solves the compensating problem of the pipeline under the circumstance of not changing the main shape of the pipeline, and the stress of the pipeline is not changed greatly, too. The operating flowing state of solids or fluids in the pipeline is notaffected, and the multifunctional compensator has a good sealing property. The multifunctional compensator is primarily applied to conveying solids, gas and liquids of industries such as food, building materials, coal, war industry, post and telecommunications and iron and steel. By adopting the special compensator provided by the invention, failures of a pipeline system can be reduced, normal useof the system can be guaranteed, and the investment and the operating cost of equipment are saved. In a word, the multifunctional compensator provided by the invention is relatively simple in structure, convenient to mount, low in cost, easy to operate and maintain and good in using effect.

Owner:惠忠州

Heavy-duty electro-hydraulic actuator-driven valve system with compensation

ActiveCN104405711BSolve a spring-bound puzzleSolving Compensation IssuesOperating means/releasing devices for valvesServomotor componentsValve actuatorElectro hydraulic

The invention provides an overload electrohydraulic executing mechanism drive valve system with a compensation function, and aims to solve the problem that CN101709807 is constrained by a spring and thus cannot be applied to the overload electrohydraulic executing mechanism drive valve system. The key points are that the system comprises a drive oil cylinder, a compensation oil cylinder and a spring, wherein a piston rod of the drive oil cylinder is connected with a valve rod of an overload valve; a piston rod of the compensation oil cylinder is abutted against the spring; the compensation oil cylinder is connected with the drive oil cylinder in parallel. The system has the positive effects that energy is absorbed, stored and released by the spring and the compensation oil cylinder together, the spring is not a unique involved part, the problem of spring constraint is solved, further the application to the overload electrohydraulic executing mechanism drive valve system is realized, and reliable operation of the overload electrohydraulic executing mechanism drive valve system is guaranteed.

Owner:SHENYANG NORTHEAST ELECTRIC POWER CONTROL

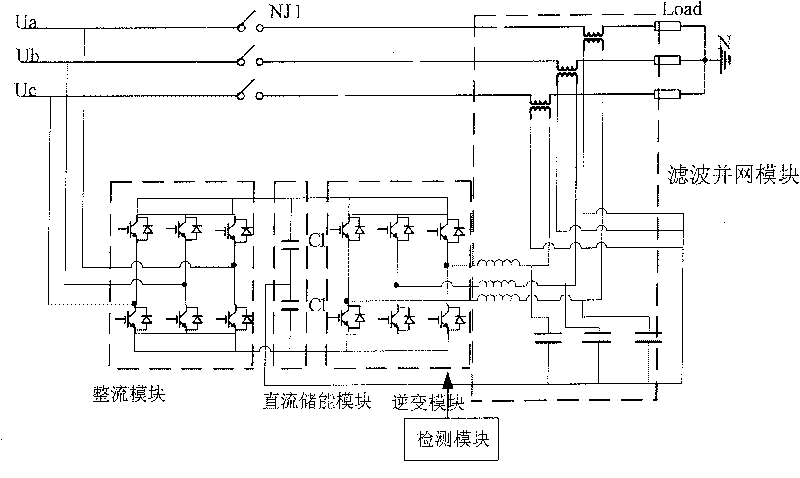

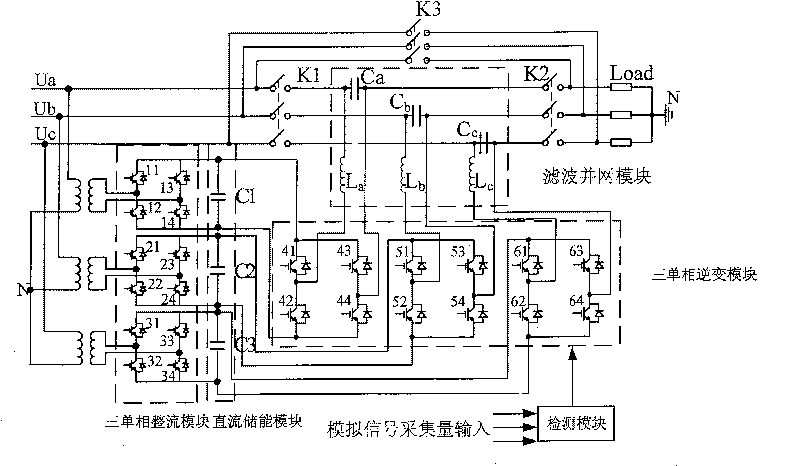

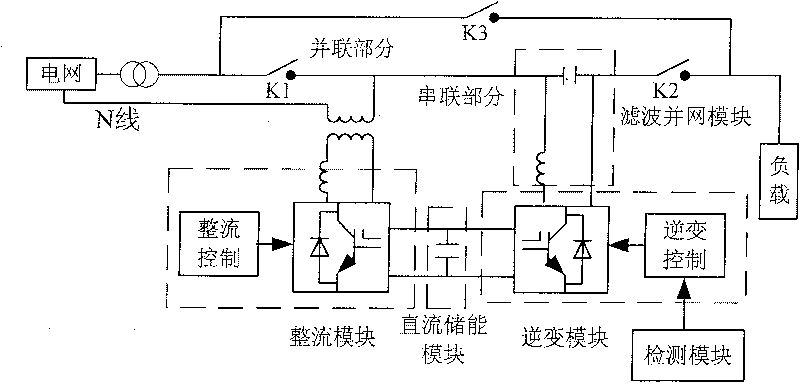

Dynamic voltage compensator adopting 3 phase structure

ActiveCN101291057BSolving Compensation IssuesDoes not affect normal workConversion with intermediate conversion to dcAc-dc conversionCapacitanceFull bridge

The invention relates to a dynamic voltage compensator adopting a three-single phase structure, wherein three-phase alternating voltage of electric grid is inputted to a rectification module; the rectification module adopts a PWM control three single phase full bridge circuit with rectification controlling unit output; the direct current voltage of the rectification module is inputted to a directcurrent energy storage module formed by direct current capacitances; the direct current of the direct current energy storage module is inputted to an inversion module; the inversion module adopts thePWM control three single phase full bridge circuit with inversion controlling unit output; the inversion module is inputted to a filtering synchronization module; the filtering synchronization moduleformed by an LC circuit is directly connected with the electric grid in series by capacitances; a detection module is inputted with voltage-current analog quantity signals of a system, and the outputof the detection module, which is used as a reference wave component, is sent to the inverter controlling unit. The dynamic voltage compensator has the advantages that the compensator thoroughly resolves the problem of unbalanced compensation of three phase voltage, and three phases can also independently work and other two phases can continue to work normally even if one phase is out of work.

Owner:SHANGHAI POWER TRANSMISSION & DISTRIBUTION CO LTD

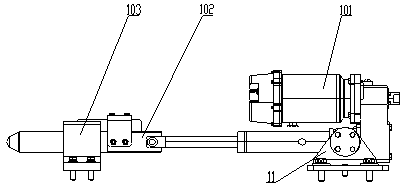

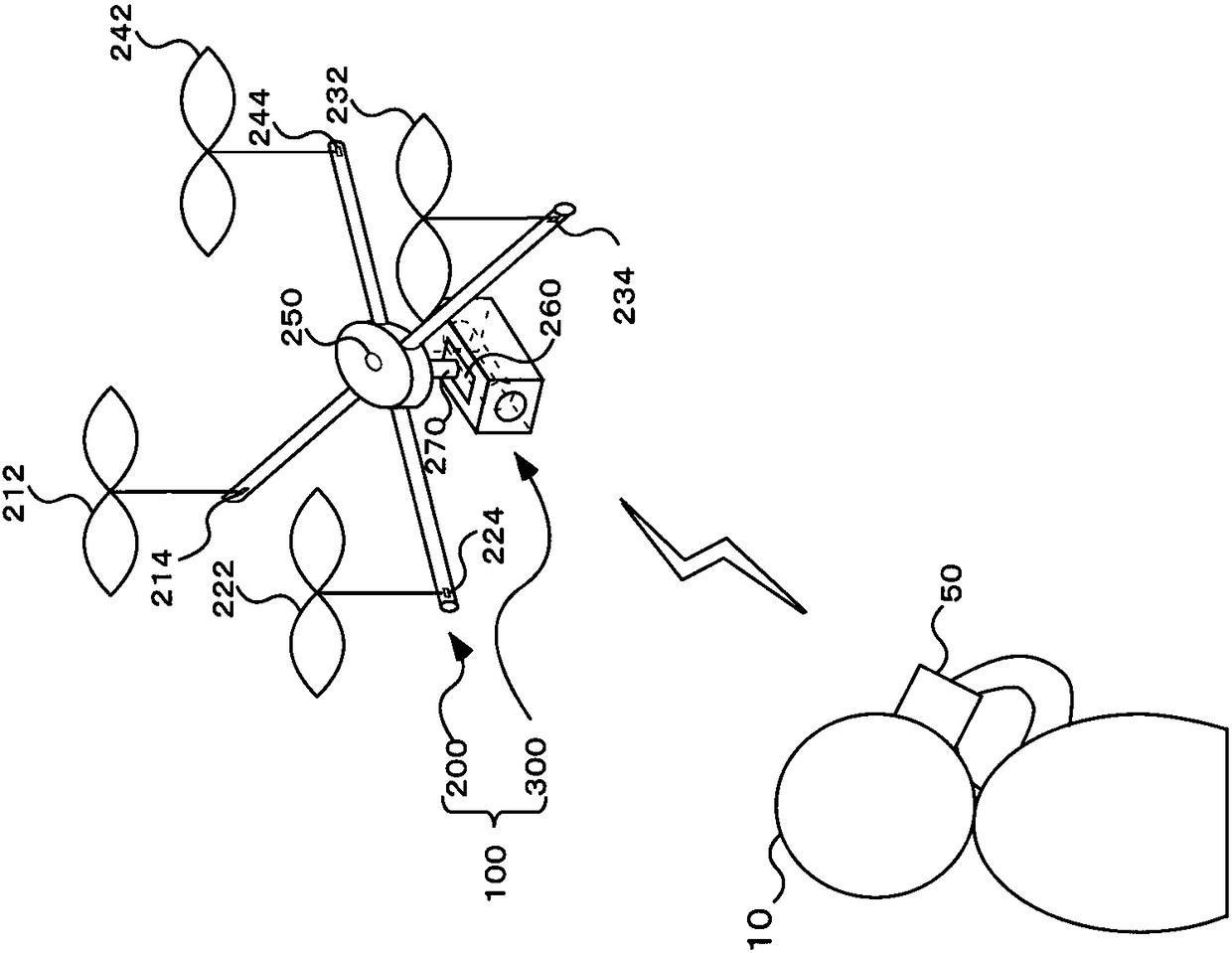

Optical axis variation compensation device and compensation method for lens module of unmanned aircraft

ActiveCN105759535BSolving Compensation IssuesImprove stabilityPrintersProjectorsOptical axisClassical mechanics

The invention discloses an optical axis variation compensating device for a lens module of an unmanned aircraft and a compensating method thereof. As for the driving part of the angle of the fuselage, the driving part controls the rotation angle of the imaging device. In the optical axis variation compensation device and compensation method of the lens module of the unmanned aircraft, when the lens in the camera device moves and the center of gravity shifts, the drive unit provided on the camera device controls the rotation angle of the camera device for Compensation, the compensation data is adjusted according to the matching angle of the moving distance of the lens, which solves the compensation problem of the unmanned aircraft when the optical axis changes, improves the stability of the shooting picture, and obtains high-quality pictures. The present invention is applicable to the field of unmanned aerial vehicles.

Owner:JCD GUANG ZHOU OPTICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com