Locking and turning device for suspension type air rail turnout interface

A flipping device and suspension technology, which is used in cable railways, transportation and packaging, motor vehicles, etc., to achieve the effect of improving reliability, good manufacturing process, and ensuring smooth passage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

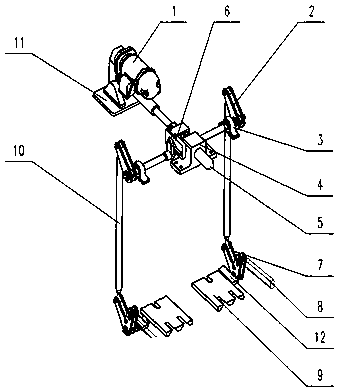

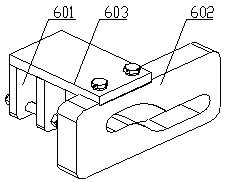

[0021] Embodiment 1: with reference to attached figure 1 , 8 ,9. A suspension-type locking and flipping device for an empty track fork interface. The power output end of the electric push rod 1 is hinged to one end of the locking pin 5 and drives the cam mechanism 6 to perform linear motion. The cam mechanism 6 drives the crank mechanism to operate and the locking pin has a timing difference. The crank mechanism 2, the connecting rod assembly 10 and the flipping crank assembly 7 form a hinge four-bar mechanism, and the crank mechanism 2 drives the horizontal lock pin 8 and the flipping finger plate 9 to rotate through the connecting rod assembly 10 and the flipping crank assembly 7 to realize locking The horizontal locking of pin 5 and the turning over of horizontal lock pin 8 and turning finger plate 9. A lower bearing seat 12 is provided between the turning crank assembly 7 and the turning plate 9 .

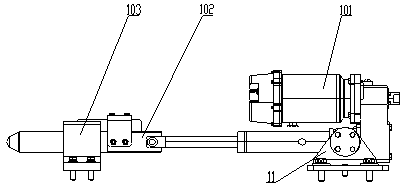

[0022] Refer to attached figure 2 . The electric push rod 1 pushes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com