Thermal temperature rise compensating method for numerical-control machine tool

A CNC machine tool, heat and temperature technology, applied in metal processing mechanical parts, maintenance and safety accessories, measuring/indicating equipment, etc., can solve the problems of high price, error compensation, poor machining accuracy, etc., and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

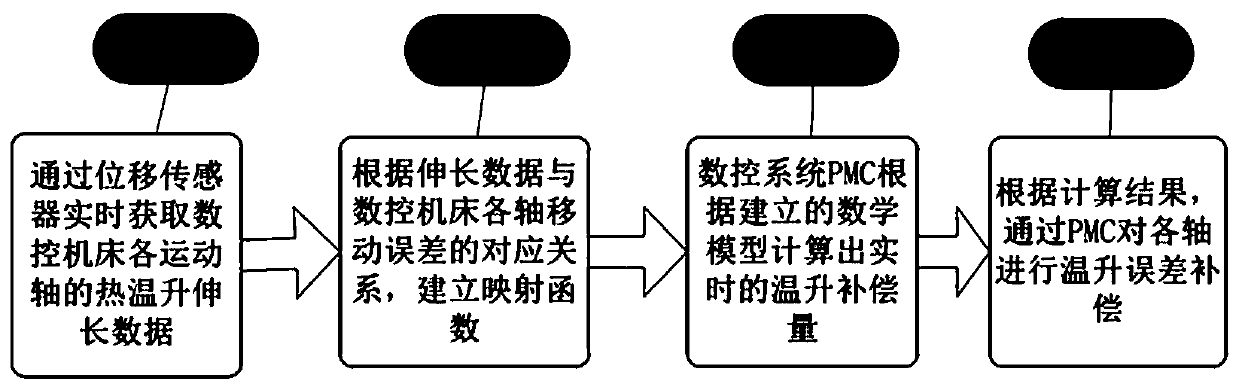

[0024] A: The elongation data of the ball screw under the thermal state of each motion axis is obtained in real time through the displacement sensor.

[0025] In step A, the thermal temperature rise of each moving axis will reach a saturation value, and in this case the measured value of the displacement sensor remains unchanged.

[0026] The method of step A can be used to pre-install displacement sensors on the CNC machine tool with the same structure to detect the elongation of the ball screw of each movement axis under the change of temperature rise.

[0027] B: According to the corresponding relationship between the elongation data of the ball screw and the movement error of each axis of the CNC machine tool under the thermal state of each movement axis, a mapping function between the two is established;

[0028] In step B, the actual displacement error variation of each axis of the CNC machine tool can be obtained by detecting the displacement variation of each motion ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com