Compound expansion joint used in petrochemical field

An expansion joint and duplex technology, which is applied in the field of expansion joints, can solve the problems of increasing the price of expansion joints and the cost of device construction, and achieve the effects of relatively low cost and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

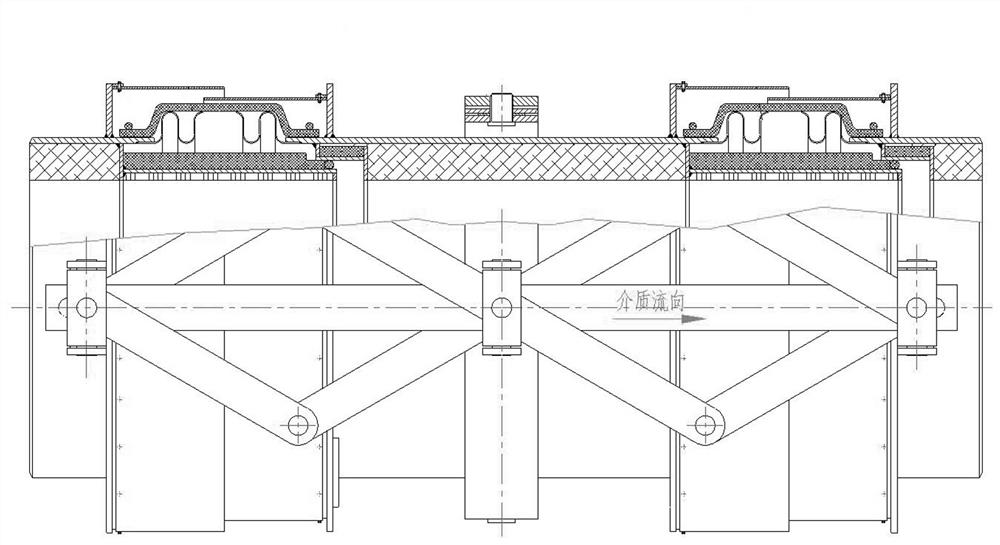

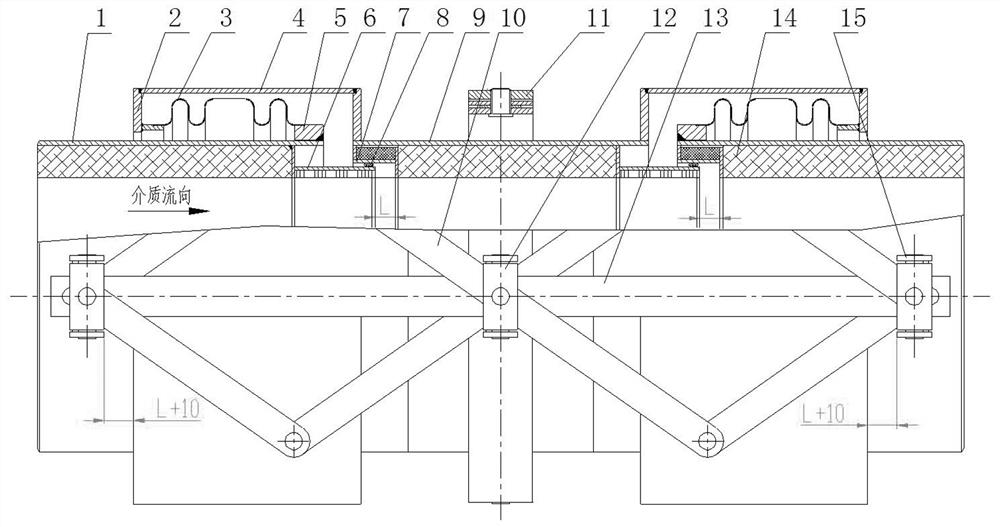

[0033] Such as figure 2 As shown, the bellows 3 of the expansion joint is an external pressure structure, one end of the bellows 3 is fixed on the end pipe through the bellows adapter 5, one end of the bellows 3 is connected to the end ring assembly 2, and the end ring assembly 2 is connected to the outer pipe 4 and the middle The pipe assembly 9 forms the external pressure cavity of the bellows 3. During operation, the pressure of the medium enters the external pressure cavity through the gap between the guide cylinder assembly 6 with wear-resistant lining and the retaining ring assembly 7 with heat-insulating ceramic fiber. cavity. A dust-proof sealing ring 8 is arranged between the guide tube assembly 6 with wear-resistant lining and the retaining ring assembly 7 with heat-insulating ceramic fiber, which is used to prevent smoke and dust from entering the external pressure cavity. Two sets of corrugated pipes 3 and two end pipes 1 are symmetrically arranged around the mid...

Embodiment 2

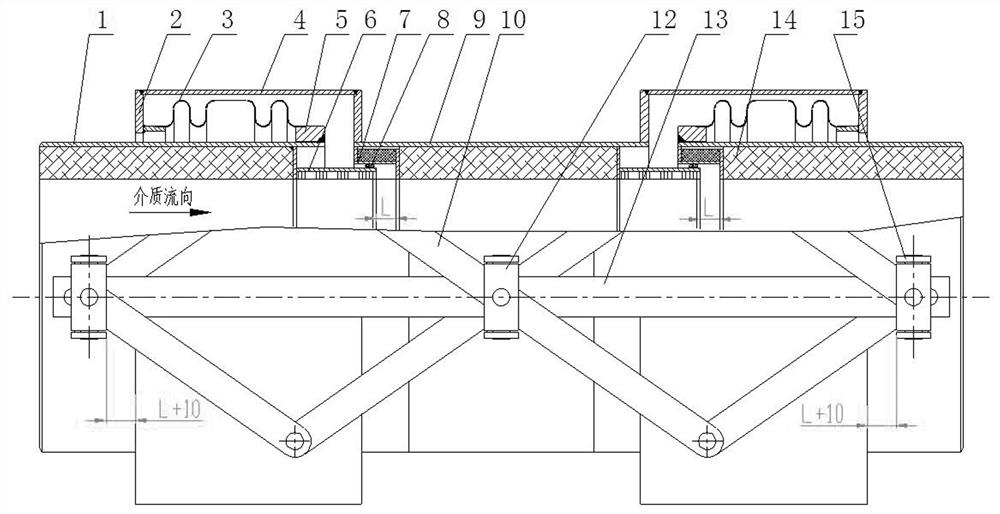

[0037] Such as image 3 As shown, the structure of this type of expansion joint is a planar proportional connecting rod structure. figure 2 The universal ring assembly 11 is missing, which is used to compensate the axial displacement and the lateral displacement of a plane.

Embodiment 3

[0039] Such as Figure 4 As shown, the bellows 3 of this type of expansion joint is an external pressure structure, one end of the bellows 3 is fixed on the end pipe through the bellows adapter 5, one end of the bellows 3 is connected to the end ring assembly 2, and the end ring assembly 2 is connected to the outer pipe 4 It forms the external pressure cavity of the bellows 3 with the intermediate pipe assembly 9. When working, the pressure of the medium enters the outer chamber through the gap between the guide cylinder assembly 6 with wear-resistant lining and the retaining ring assembly 7 with heat-insulating ceramic fiber. pressure cavity. A dust-proof sealing ring 8 is arranged between the guide tube assembly 6 with wear-resistant lining and the retaining ring assembly 7 with heat-insulating ceramic fiber, which is used to prevent smoke and dust from entering the external pressure cavity. The two groups of corrugated pipes 3 and the end pipes 1 are arranged symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com