A fan blade vibration detection device and fault detection and prediction method

A technology for vibration detection and failure prediction, applied in measurement devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inability to analyze and predict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

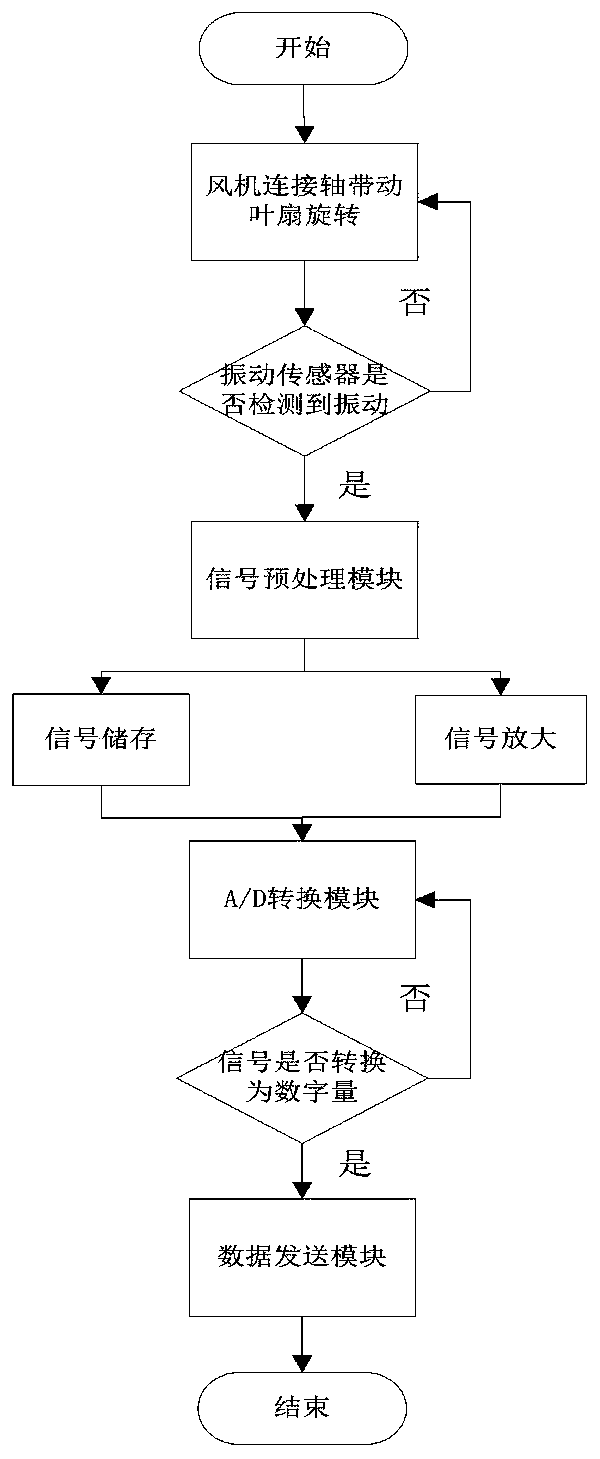

[0063] A fan blade vibration detection and fault prediction system comprises a fan blade vibration detection device and a fan fault prediction method.

[0064] 1.1 A fan blade vibration detection device

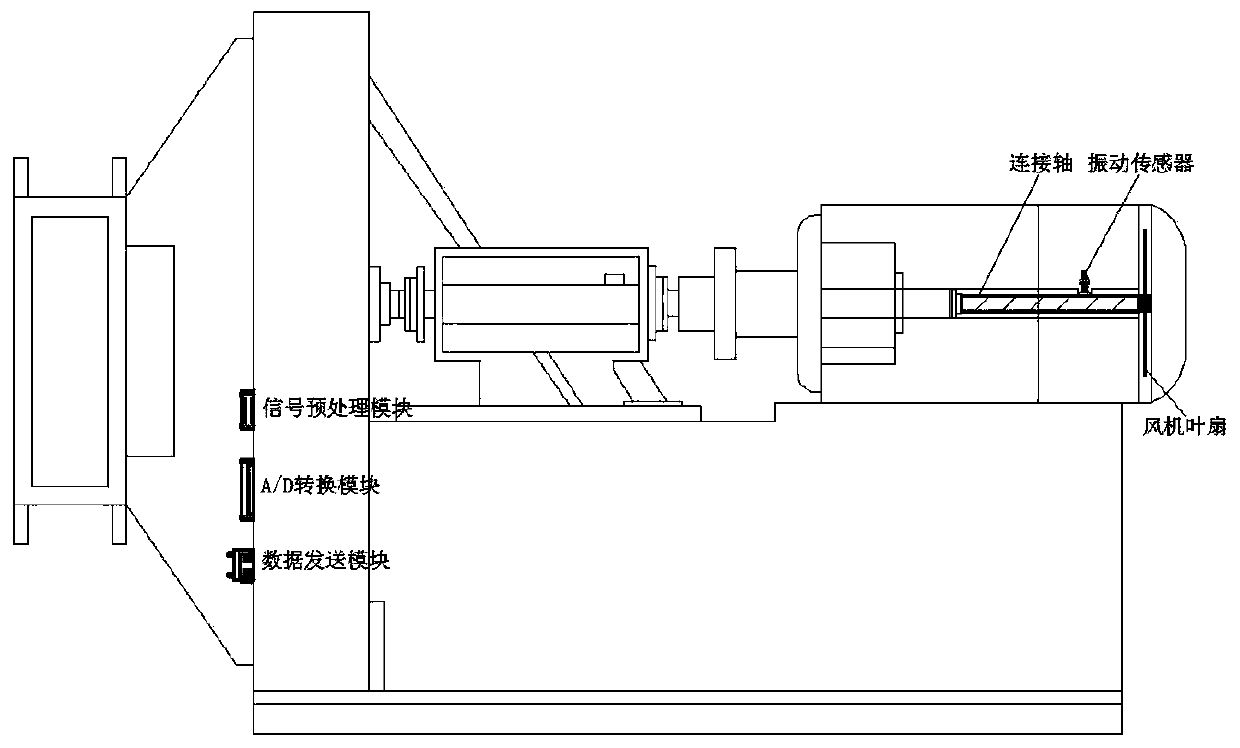

[0065] Its structure is as figure 1 As shown, a fan blade vibration detection device includes a vibration sensor, a signal preprocessing module, an A / D conversion module and a data transmission module.

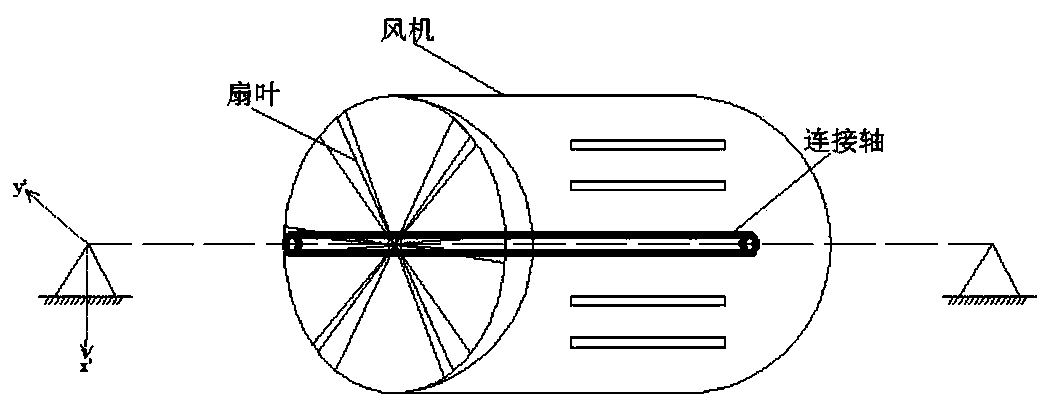

[0066] The vibration sensor is installed on the connecting shaft, and takes the vibration mechanical quantity of the connecting shaft as an input quantity, which is received by its receiving part and converted into electrical pulse output. The vibration generated by the fan during operation mainly comes from the connecting shaft. The connecting shafts with different outer diameters (sz2) and inner diameters (sz1) have different vibration amplitudes during operation for a period of time (t) (that is, dynamic displacement τ) , this vibration amplitude will affect the two crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com