Rotating compensator for corrosion resistant pipeline and preparation method and compensating system

A kind of rotary compensator and corrosion-resistant technology, which is applied in the direction of expansion compensation device, pipe element, pipe/pipe joint/pipe fitting, etc. for pipelines. The effect of large compensation distance, increased conveying pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

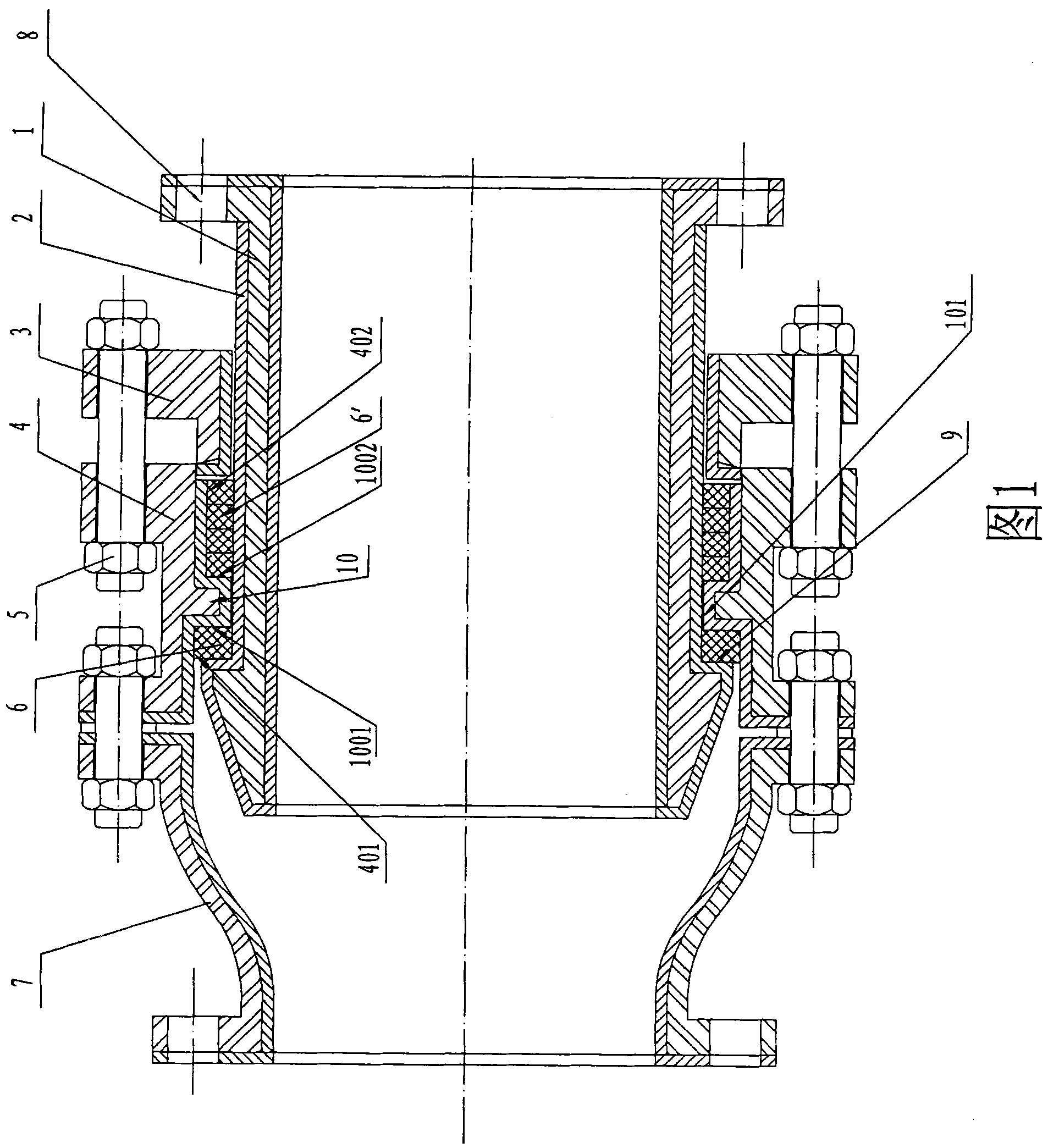

[0031] like figure 1 shown.

[0032] A rotary compensator for corrosion-resistant pipelines, comprising a rotary connecting pipe 1, a sealing gland 3, a sealing seat 4 and a cone connecting pipe 7, one end of the rotary connecting pipe 1 is welded with a connecting flange 8 (this is for It is convenient for the sealing seat 4 to be conveniently set on the rotating connecting pipe 1. Only when the sealing seat 4 is set on the rotating connecting pipe 1 can the connecting flange 8 be connected to the rotating connecting pipe 1 by welding, and then through the connecting flange when in use. 8 is connected with the delivery pipeline), its other end is conical and is provided with a step surface 9, and the conical end stretches into the conical connecting pipe 7 that is also conical, and the two ends of the sealing seat 4 are respectively provided with a connecting method It is set on the rotating connecting pipe 1. When compensation is required, the sealing seat 4 and the rotatin...

Embodiment 2

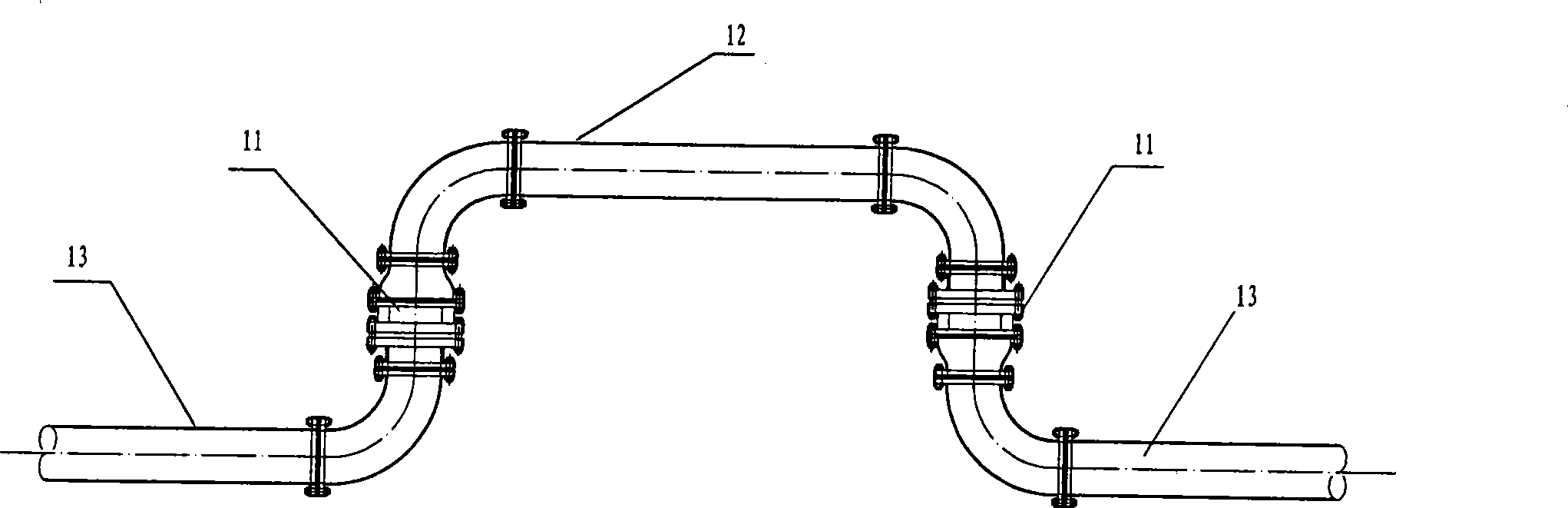

[0043] like figure 2 , 3 shown.

[0044] A linear length compensation system equipped with a corrosion-resistant pipeline compensator, which includes two corrosion-resistant pipeline rotary compensators 11 and a connecting pipe 12, the center line of the corrosion-resistant pipeline rotary compensator 11 is connected to the The center line of the conveying pipeline 13 is perpendicular, and the two ends of the connecting pipe 12 pass through respective elbows (which can be connecting elbows or integral structure elbows, figure 2 What is shown is a connecting pipe (12) with a connecting elbow connected to the inlet or outlet of the corresponding corrosion-resistant pipeline rotary compensator 11. The delivery pipeline 13 is connected to the inlet or outlet of the corresponding corrosion-resistant pipeline with the rotary compensator 11 through a connecting elbow, such as figure 2 as shown, figure 2 The conveying pipelines 13 described in are parallel but not on the same ...

Embodiment 3

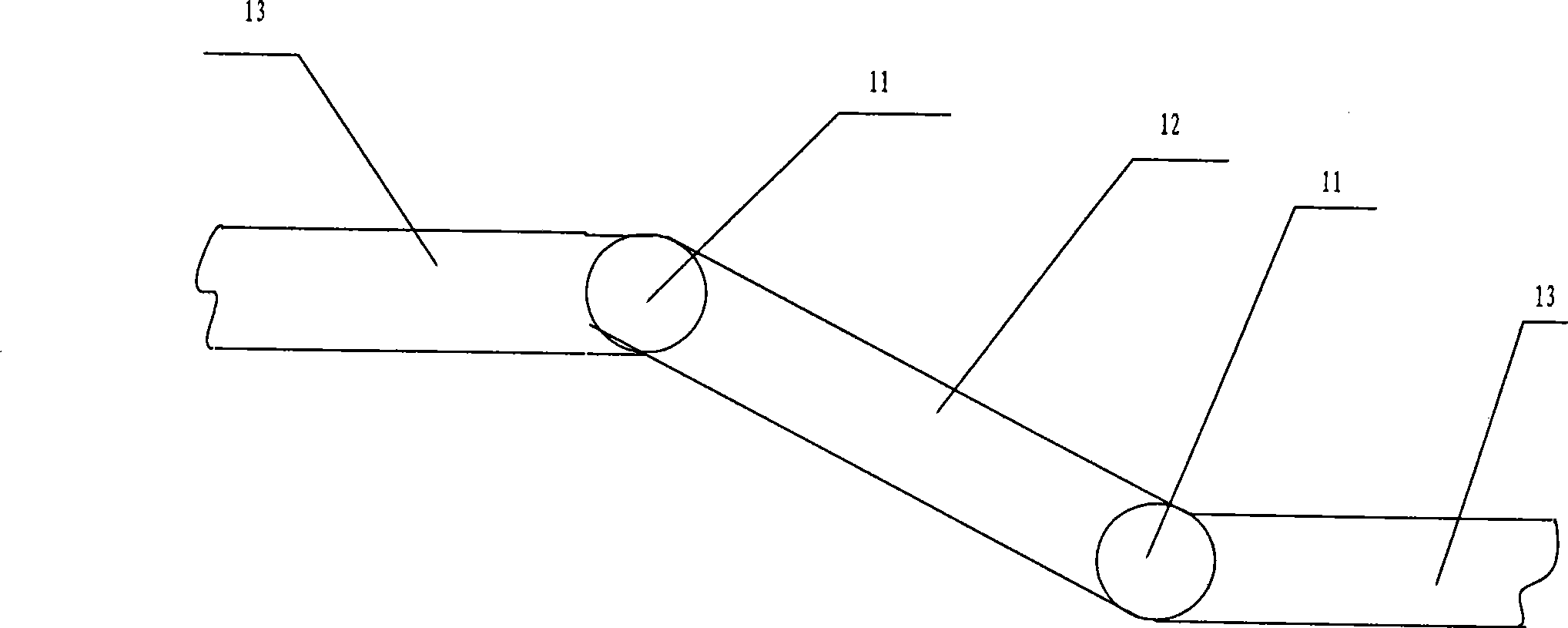

[0047] like Figure 4 shown.

[0048] The difference between the present embodiment and the second embodiment is that the medium delivery pipes 13 are located on the same straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com