Volume-type fluid mechanism

A fluid mechanism and volumetric technology, applied in liquid fuel engines, mechanical equipment, machines/engines, etc., can solve problems such as leakage, low efficiency, and short service life of fluid mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

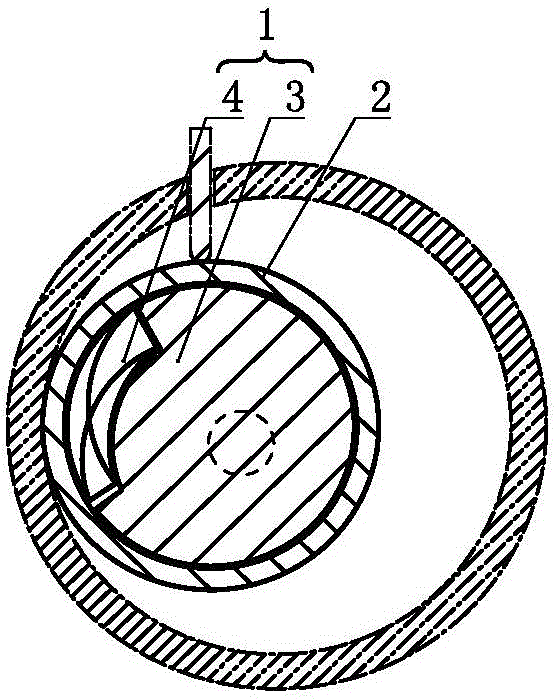

[0152] A volumetric fluid mechanism such as figure 1 As shown, the volumetric fluid mechanism includes an eccentric shaft 1 and a working medium moving part 2, the eccentric shaft 1 includes a drive shaft 3 and a deflection non-sleeve body 4, and the deflection non-sleeve body 4 is arranged on the drive shaft 3 The rotating shaft and / or the deflection non-sleeve body 4 is arranged on the eccentric part of the drive shaft 3 , and the working medium moving part 2 is sleeved on the drive shaft 3 and the deflection non-sleeve body 4 .

[0153] In a specific implementation, the working medium moving part 2, the drive shaft 3 and the deflection sleeve 4 can be combined with a cylinder to form a volumetric fluid mechanism.

Embodiment 2

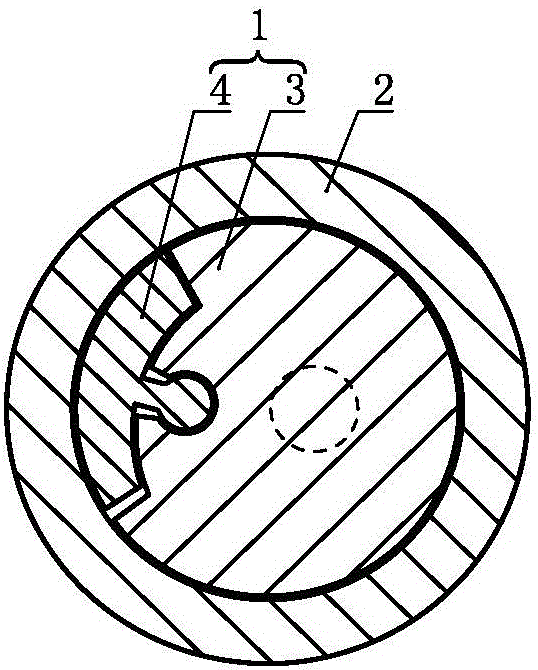

[0155] A volumetric fluid mechanism such as figure 2 As shown, on the basis of Embodiment 1, the deflection non-sleeve body 4 can be further selectively arranged on the rotating shaft of the drive shaft 3 through a hinge structure or on the eccentricity of the drive shaft 3 through a hinge structure. department.

[0156] As a changeable implementation mode, in Embodiment 1 and Example 2 and their changeable implementation forms, the deflection non-sleeve body 4 can be further set as an eccentric deflection non-sleeve body or as a non-eccentric deflection non-sleeve body. body.

Embodiment 3

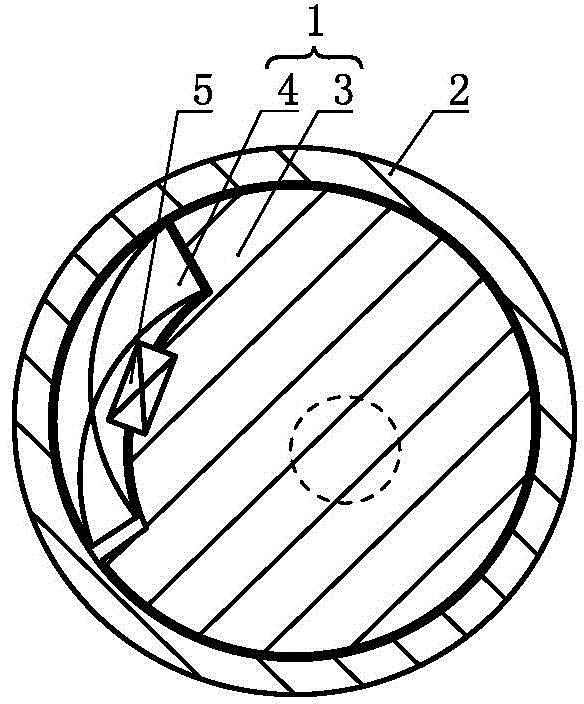

[0158] A volumetric fluid mechanism such as image 3 As shown, on the basis of Embodiment 1, further optionally between the deflection non-sleeve body 4 and the shaft of the drive shaft 3 and / or between the deflection non-sleeve body 4 and the drive shaft A rotation angle control device 5 is arranged between the eccentric parts of 3.

[0159] As a transformable embodiment, in Embodiment 1 and Embodiment 2 and their transformable embodiments, it is possible to further select between the deflection non-sleeve body 4 and the rotating shaft of the drive shaft 3 and / or a rotation angle control device 5 is provided between the deflection sleeve 4 and the eccentric part of the drive shaft 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com