Laser flare measuring device and measuring method thereof

A technology of laser spot and measuring device, which is applied in the direction of measuring device, optical device, and completely visual method, which can solve the problems of laser beam drift, affecting the authenticity and correctness of spot measurement, and achieve the effect of accurate beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

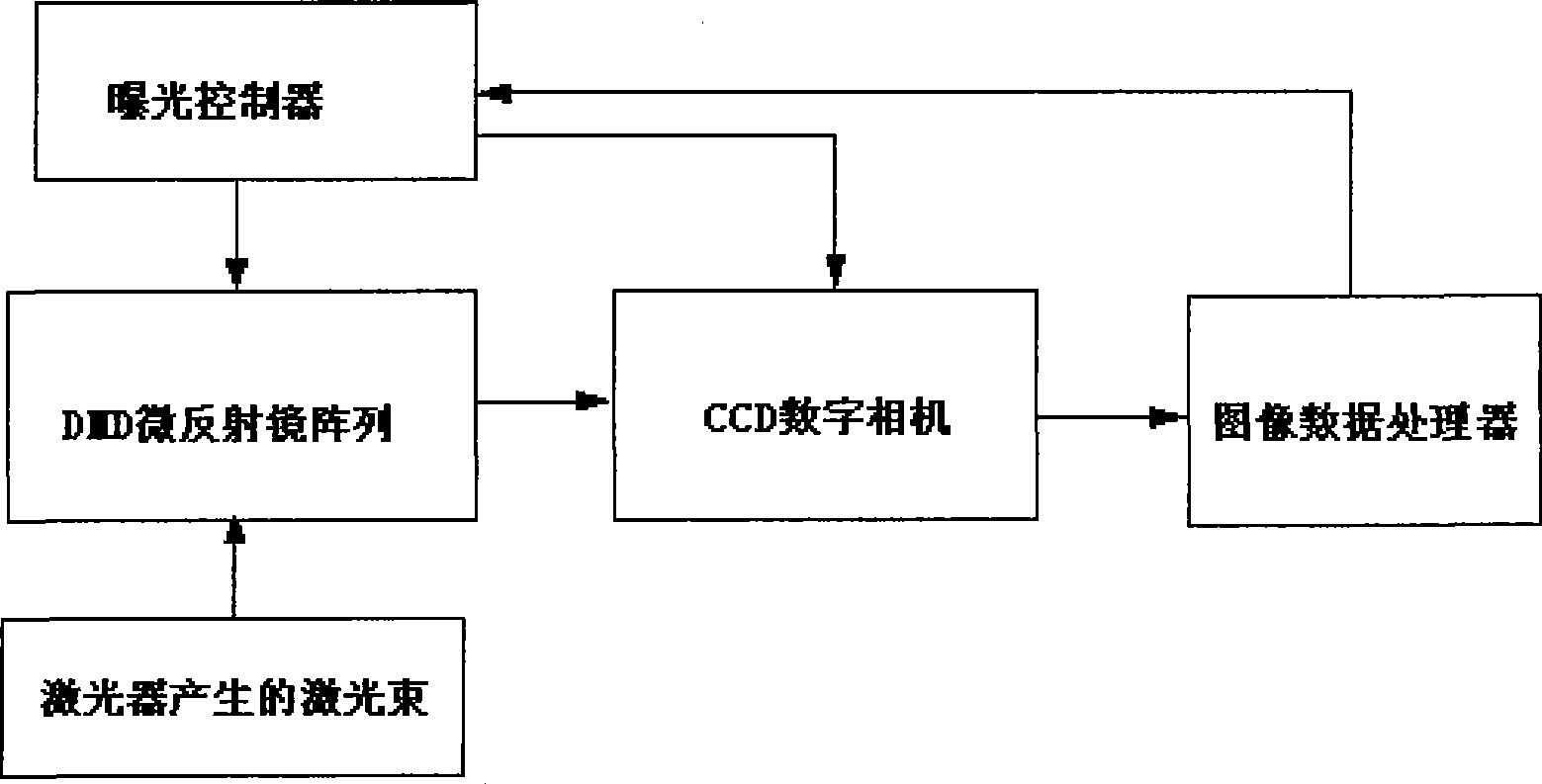

[0021] See attached figure 1 , which is a working principle diagram of the laser spot measuring device of this embodiment. The laser spot measurement device is composed of DMD micro-mirror array, CCD digital camera, exposure controller and image data processor. figure 1 Among them, one output terminal of the exposure controller sends out a signal to control the opening and closing of the shutter of the CCD digital camera, and the other output terminal outputs a signal to control the opening state of the working pixel of the DMD micromirror array; the laser beam generated by the laser is projected to the DMD micromirror array. In the center of the mirror array device, the DMD micro-mirror array device reflects the laser beam to the photosensitive surface of the CCD digital camera, and the video signal output end of the digital camera is connected to the image data processor. After being processed by the image data processor, its One output signal is fed back to the control exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com