Multi-sensor by utilizing platinum and palladium doped SO2 film and method for making same

A multi-sensor, sensor technology, applied in the direction of instruments, scientific instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

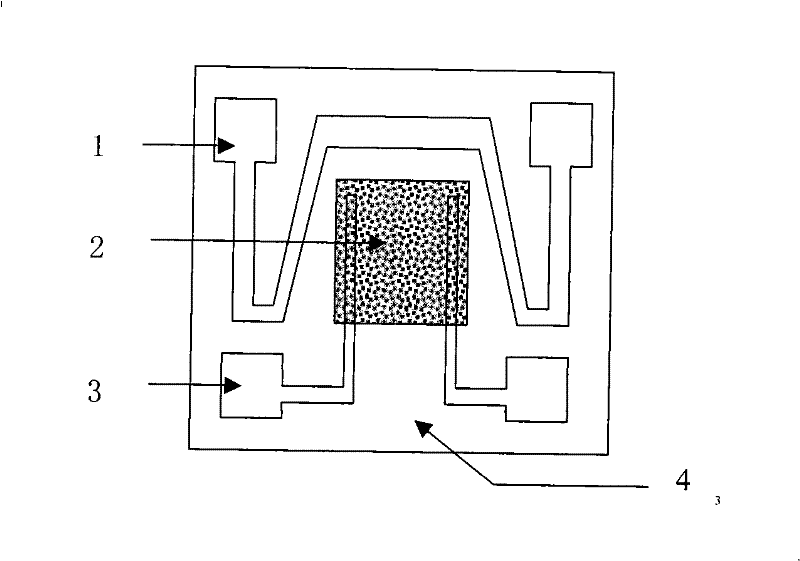

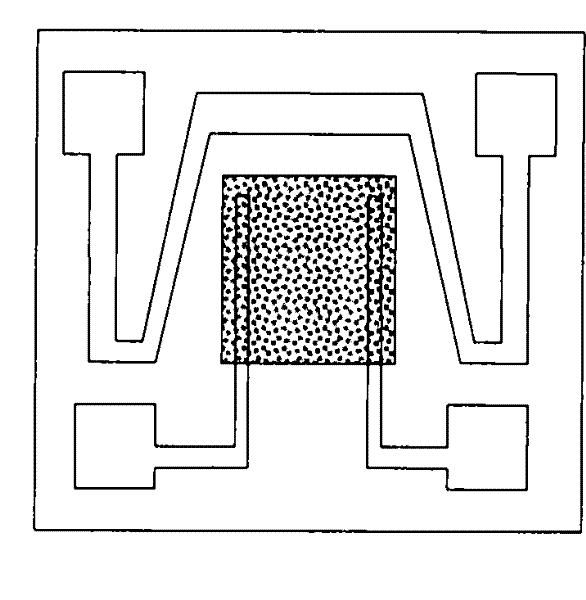

[0023] 1. Based on thermal conductivity, electrical conductivity and process requirements, Al 2 o 3 As substrate; first polish Al 2 o 3 substrate, and then deposited photoresist, after photoetching, forming such as figure 1 Deposition baths for heating electrodes and metal measuring electrodes are shown, with a thickness of 200 nm, and then the photoresist on the substrate is stripped.

[0024] 2. Soak the substrate prepared in the previous step with acetone for 5 hours, rinse it with deionized water until it is colorless; then put it into deionized water for ultrasonic cleaning twice, each time for 10 minutes; put it into absolute ethanol for ultrasonic cleaning twice, Put it into acetone and ultrasonically clean it twice, each time for 10 minutes; finally put it in an oven for drying.

[0025] 3. Dope platinum or palladium on the pure metal Sn target of the radio frequency sputtering coating equipment, and symmetrically squeeze two (50mm×1mm×0.1mm) platinum or palladium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com