Method for detecting Clenbuterol residual quantity in hair

A residue and hair technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of low detection sensitivity and specificity, limit clenbuterol residues, and complicated sample processing procedures, and achieve easy sampling and shortening of time. , Accurate and reliable qualitative and quantitative detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 pig hair sample pretreatment method

[0034] One case of negative blank pig hair and three cases of positive pig hair collected from pigs suspected to have been fed clenbuterol in a slaughterhouse, the hair samples were washed with water and methanol respectively, dried at room temperature, and then shredded to 2- 3mm fragments. Take 50mg of hair into a centrifuge tube, add 50μl of 25ng / ml internal standard working solution and 0.5ml of 2mol / L sodium hydroxide solution, vortex and mix for 1min, heat in a water bath at 90°C for 10min, take it out, and add excess Na 2 SO 4Solid, mix well, add 2.5ml ether, vortex for 5min, centrifuge at 15,000×g for 10min; absorb the upper organic phase, add 100μl of 2% (v / v) formic acid solution, vortex for 5min, centrifuge at 15,000×g for 10min; absorb the lower layer of water phase, transferred to a vial for injection.

Embodiment 2

[0035] Another pretreatment method of the pig hair sample of embodiment 2

[0036] In addition, 1 case of negative blank pig hair and 3 cases of positive pig hair in Example 1 were taken, washed with water and dichloromethane respectively, dried at room temperature, and then cut into fragments of 2-3 mm. Take 50mg of hair into a centrifuge tube, add 50μl of 25ng / ml internal standard working solution, and 1ml of 1mol / L potassium hydroxide solution, vortex and mix for 1min, heat in a water bath at 65°C for 15min, take it out, add excess NaCl solid, and mix well , add 2ml tert-butyl methyl ether, vortex for 5min, centrifuge at 15,000×g for 10min; absorb the upper organic phase, add 100μl 5% (v / v) acetic acid solution, vortex for 5min, centrifuge at 15,000×g for 10min; absorb the lower aqueous phase, transfer To the vial for injection.

Embodiment 3

[0037] Another pretreatment method of the pig hair sample of embodiment 3

[0038] Another negative blank and 3 positive pig hairs in Example 1 were taken, washed with water and 0.01mol / L dilute hydrochloric acid respectively, dried at room temperature, and then cut into fragments of 2-3 mm. Take 50mg of hair into a centrifuge tube, add 50μl of 25ng / ml internal standard working solution, 1ml of concentrated ammonia solution (25-28%, v / v), vortex and mix for 1min, heat in a water bath at 90°C for 15min, take it out, and add excess Na 2 SO 4 Solid, mix well, add 2ml of dichloromethane, vortex for 5min, centrifuge at 15,000×g for 10min; absorb the upper organic phase, add 200μl 0.5% (v / v) formic acid solution, vortex for 5min, centrifuge at 15,000×g for 10min; absorb the lower layer The aqueous phase was transferred to a vial for injection.

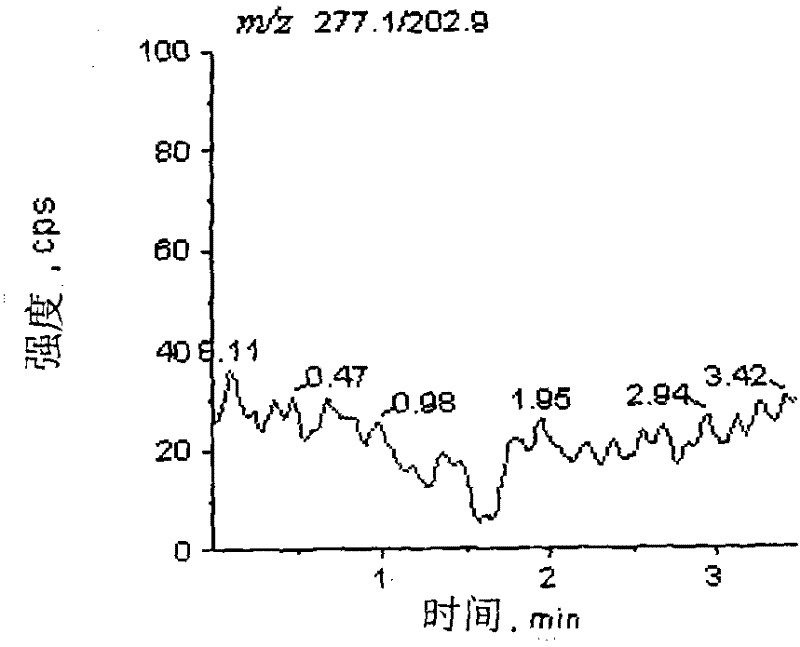

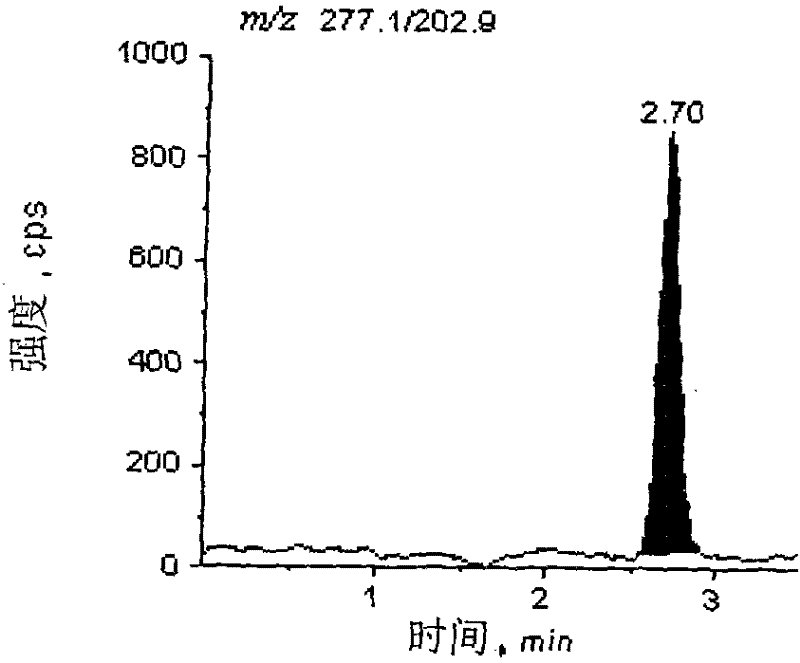

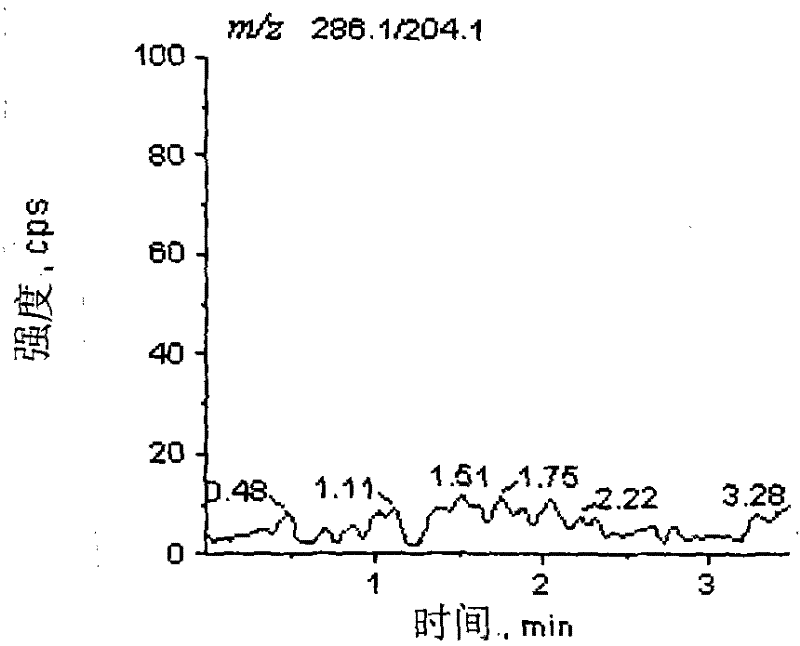

[0039] For the samples processed by the three pig hair sample processing methods in Examples 1, 2, and 3, the clenbuterol residue in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com