Imaging unit and image forming apparatus using same

A technology for imaging components and components, which is applied to the equipment of electrical recording technology applying charge patterns, electrical recording technology and instruments applying charge patterns, etc., can solve the problem of low production efficiency, improve productivity, and facilitate high-precision management. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

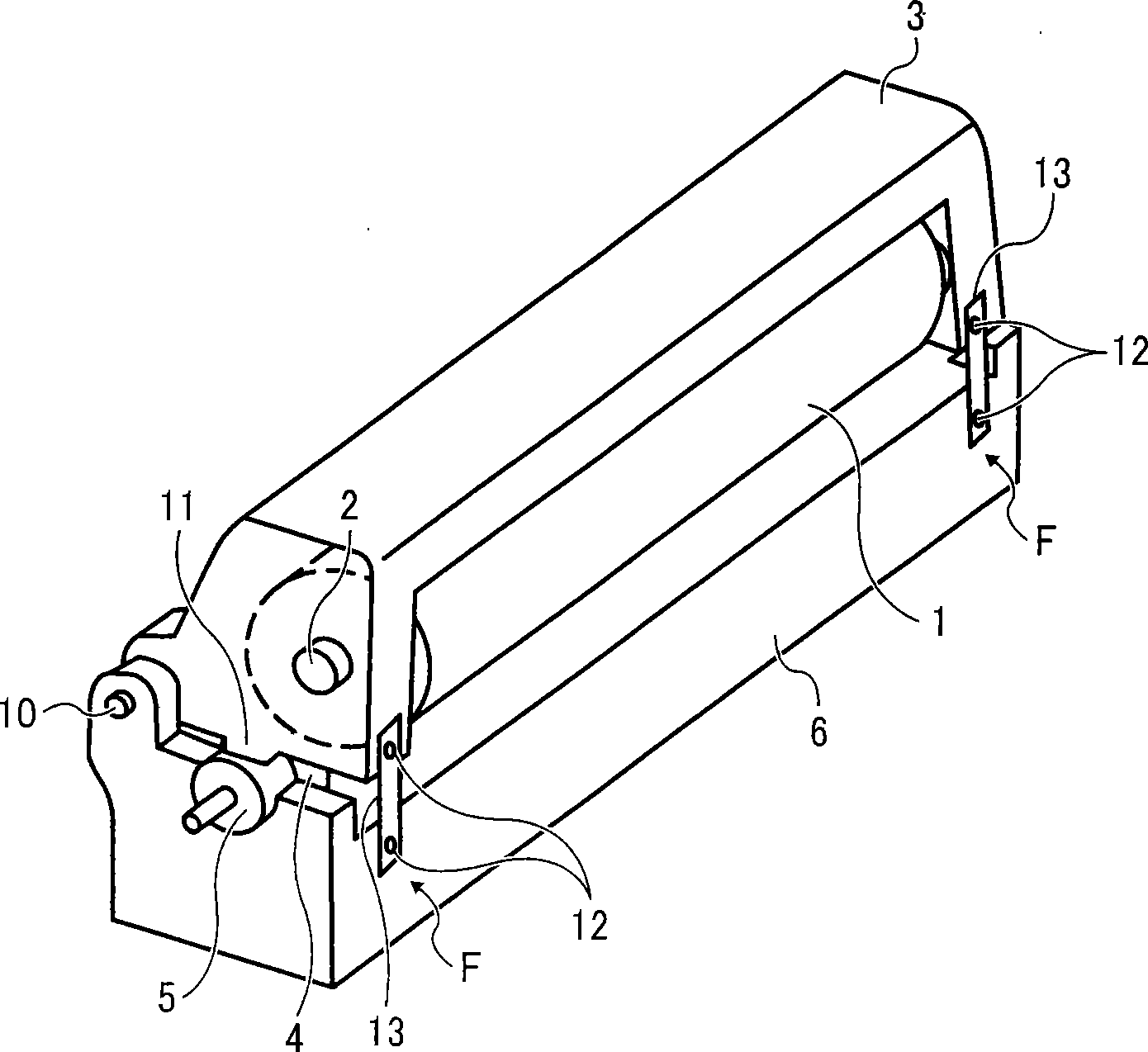

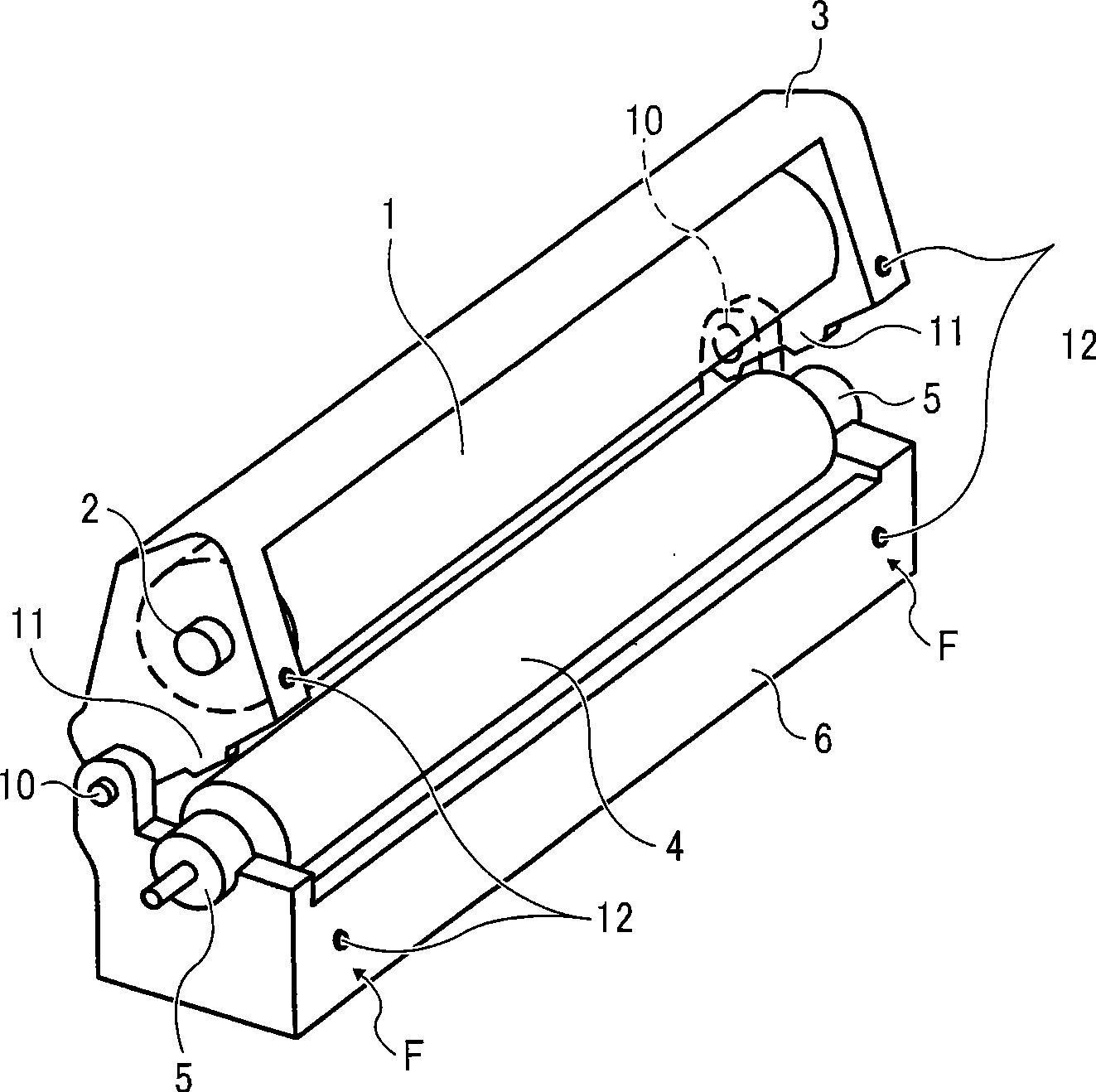

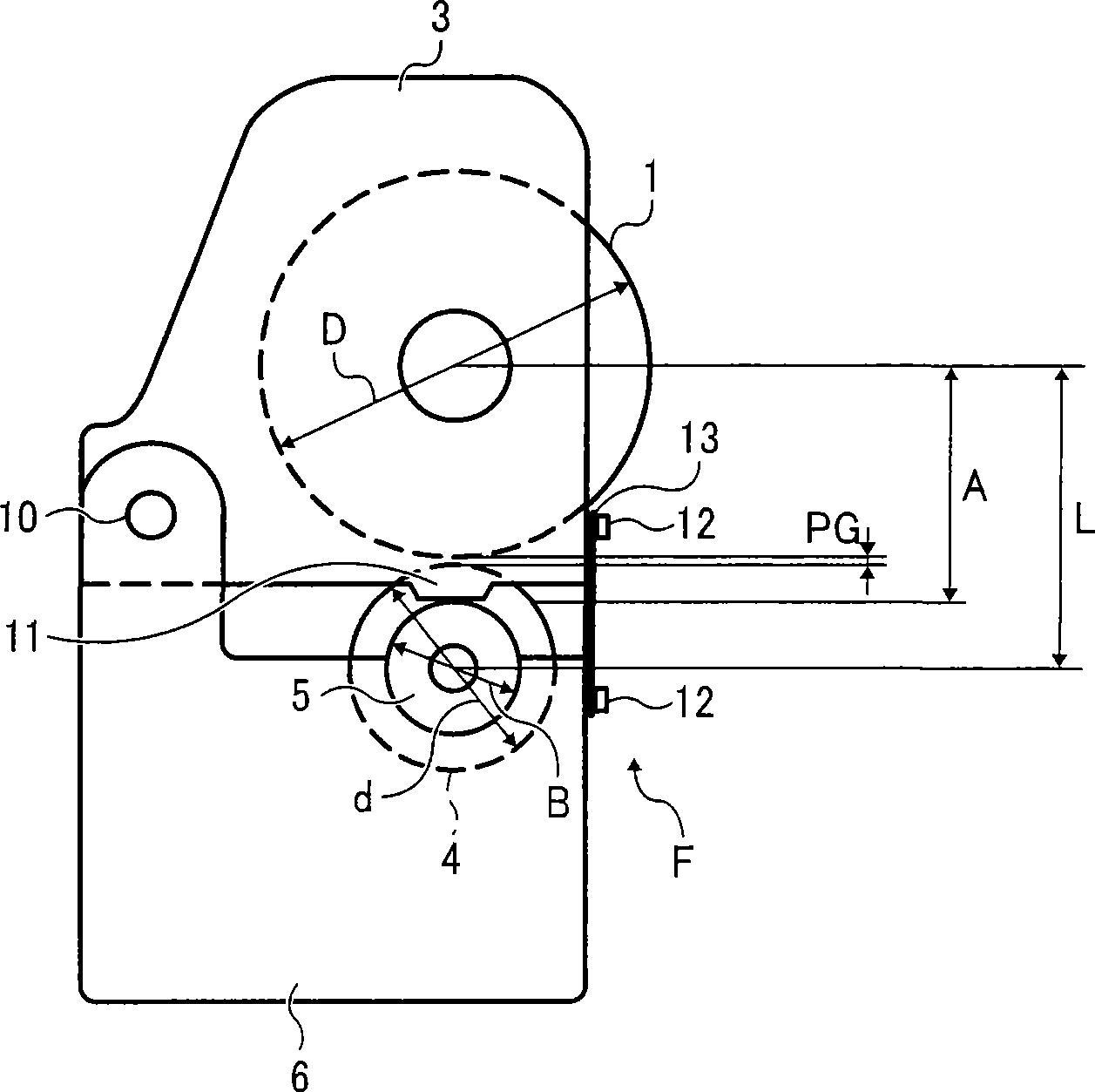

[0025] Embodiments of the present invention are described below with reference to the drawings.

[0026] figure 1 Shown is a side view of a schematic configuration of the imaging unit according to this embodiment. exist figure 1 In the imaging unit, a photoreceptor drum 1 as an image carrier is held rotatably in a photoreceptor unit (hereinafter referred to as PCU) frame 3 via bearings 2 at both end flanges (not shown). In addition, after the developing roller 4 is supported by the support member 5 embedded in the flange shaft at both ends, it is parallel to the axis of the photoreceptor drum 1 on the upper part of the developer cartridge 6 of the developer unit holding the developer through the support member 5 was shelved. The PCU housing 3 and the developer cartridge 6 are connected so as to be rotatable by a common rotation shaft 10 arranged parallel to the photoreceptor drum shaft 1. By rotating around the common rotation shaft 10, the photoreceptor drum 1 and the deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com