Twin-tub machine for making ice-cream

An ice cream and making machine technology, which is applied in the fields of frozen desserts, food science, and applications, can solve the problems of low processing efficiency, no storage of ice cubes or cooling, increased cost input, etc., and achieves improved efficiency, convenient use, and structural space. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

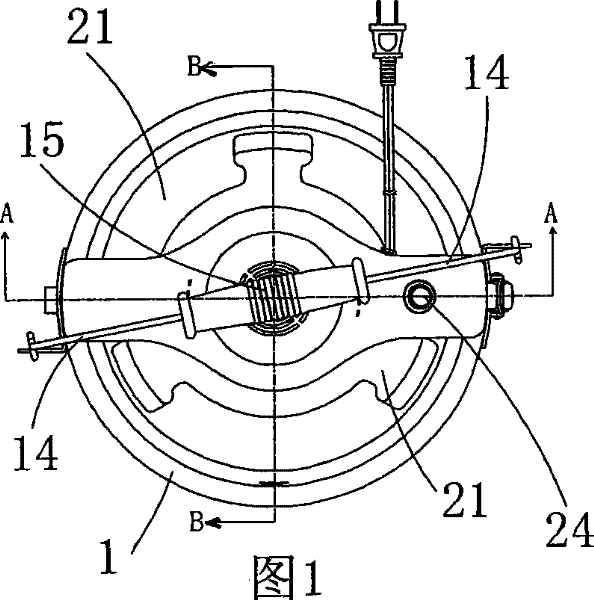

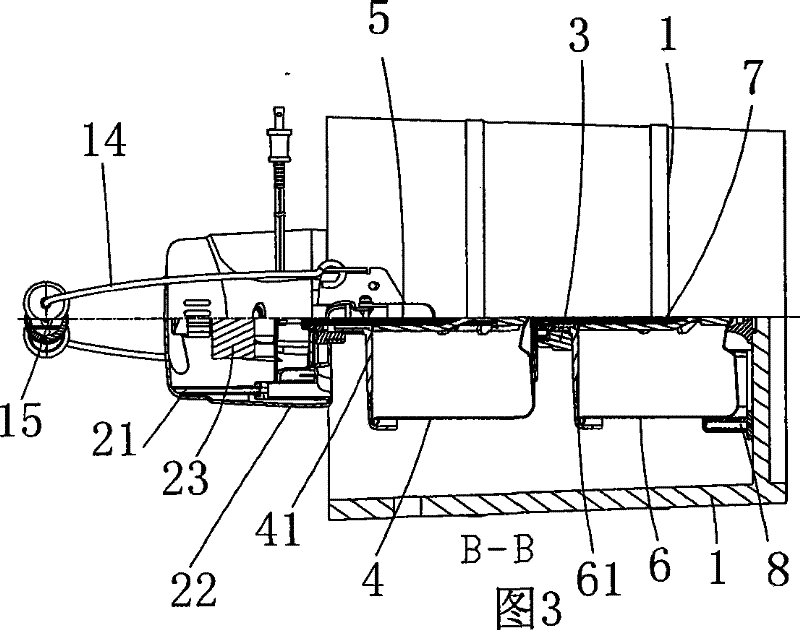

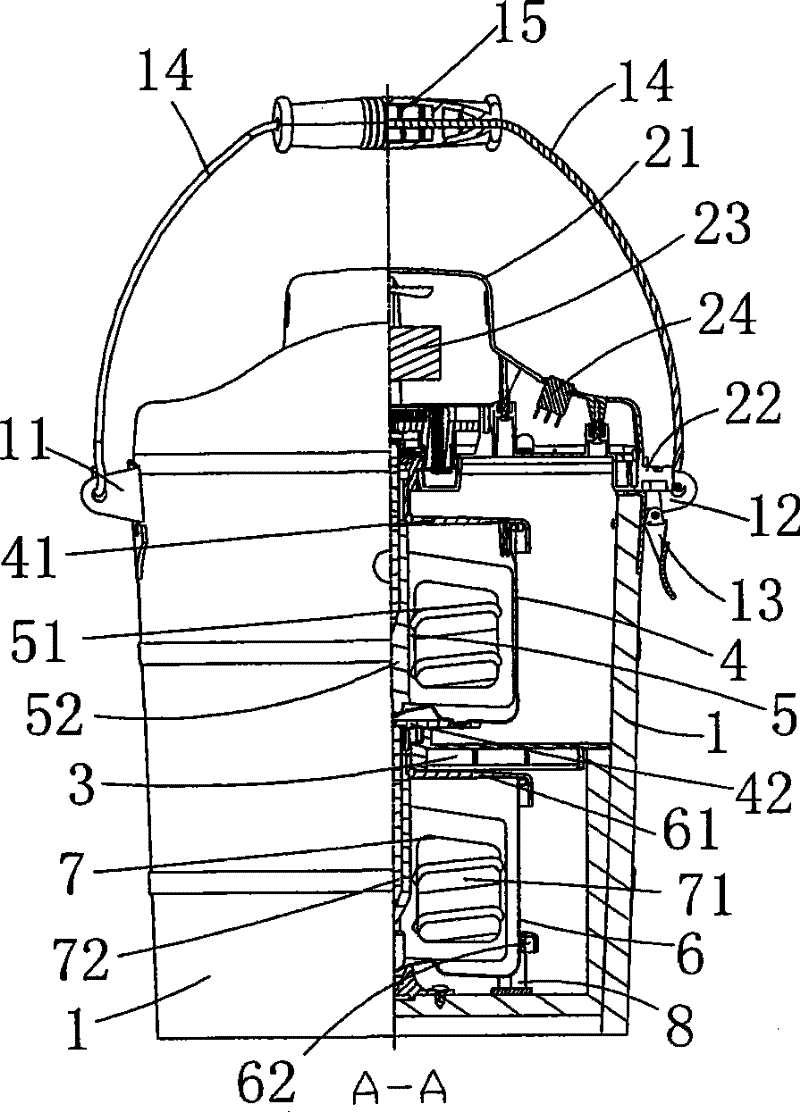

[0020] Such as Figure 1 to Figure 5 As shown, the icon numbers are as follows: barrel body 1, first lug 11, second lug 12, handle ring 13, handle 14, handle 15, motor upper cover 21, motor lower cover 22, motor assembly 23, switch 24, the fixed frame 3, the first ice bucket body 4, the first bucket cover 41, the bucket pad body 42, the first rotor blade 5, the first blade 51, the first drive shaft 52, the second ice bucket body 6, the second Bucket cover 61 , fixed ring 62 , second rotor blade 7 , second blade 71 , second drive shaft 72 , fixed ring foot 8 .

[0021] In the embodiment of the present invention, the double-barrel ice cream making machine includes a barrel body 1, and the upper edge of the barrel body 1 is equipped with a motor upper cover 21 and a motor lower cover 22. The chamber is equipped with a motor assembly 23, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com