Floating control type coolant expansion apparatus

A technology of expansion device and refrigerant, which can be used in refrigerators, liquid level control, refrigeration components, etc., and can solve problems such as complex devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

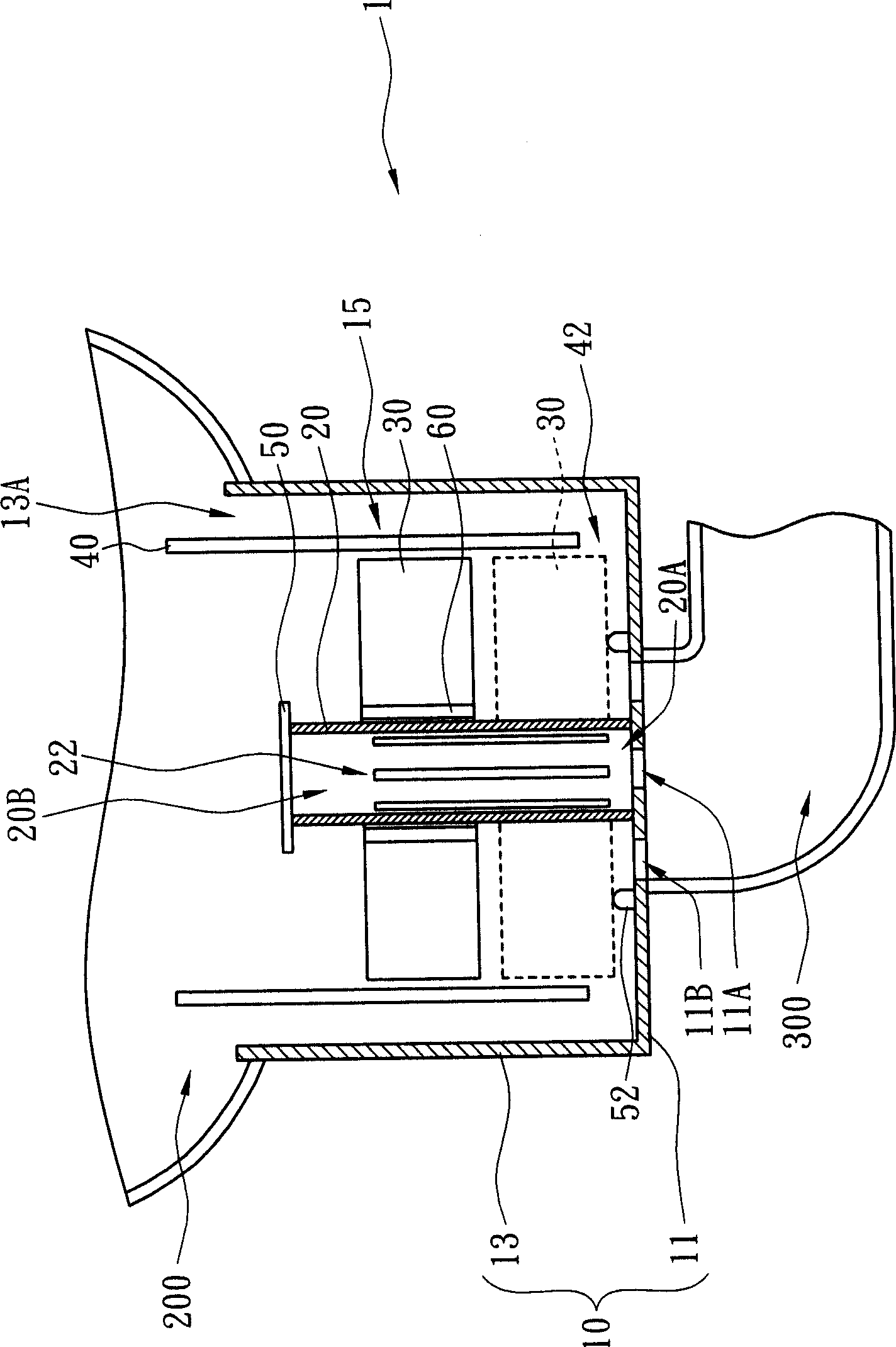

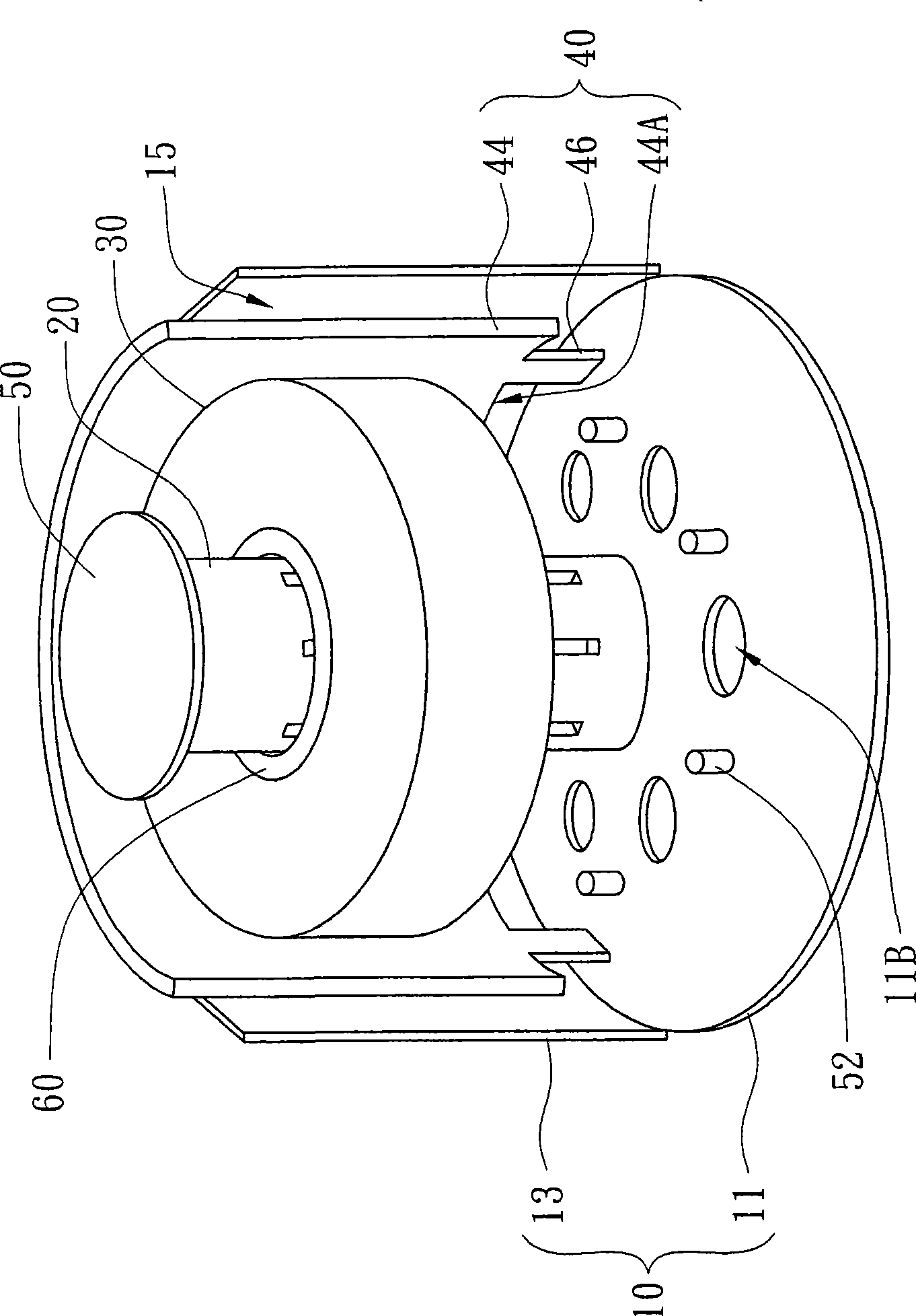

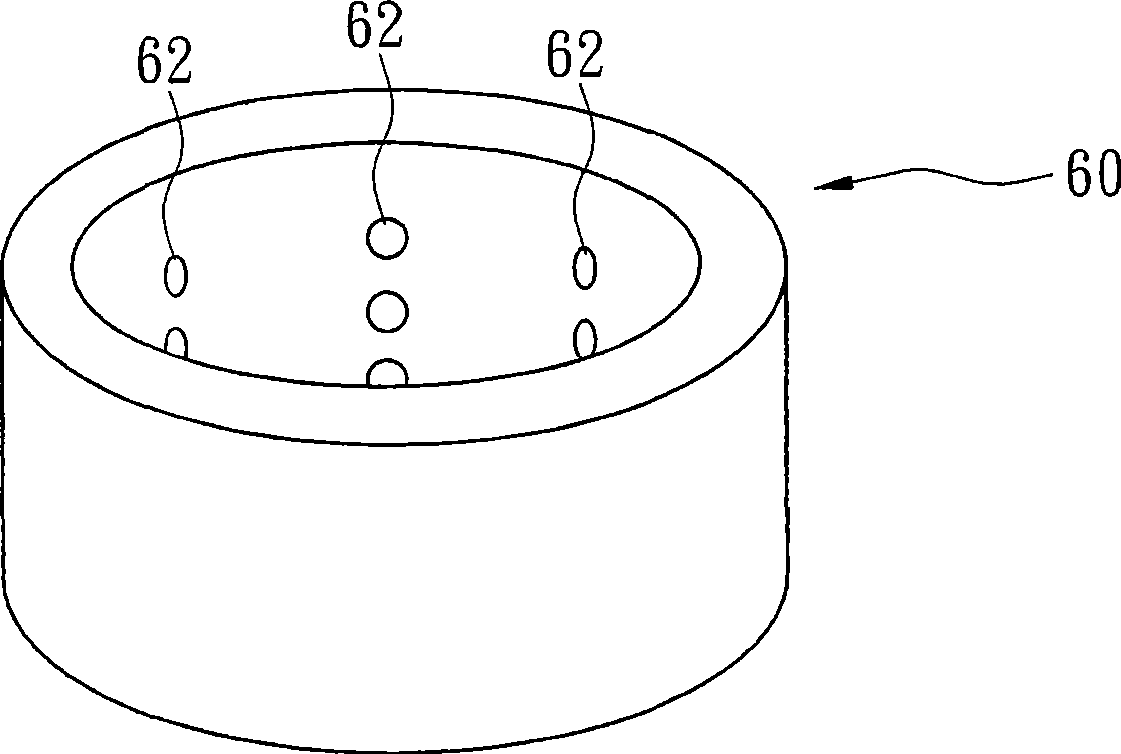

[0051] Please refer to figure 1 , figure 2 , figure 1 A schematic diagram showing a floating refrigerant expansion device according to a preferred embodiment of the present invention, figure 2 draw figure 1 A perspective view of a floating refrigerant expansion device. The float-controlled refrigerant expansion device 1 includes a buoy chamber body 10 , a vertical pipe 20 , a buoy assembly 30 and a partition assembly 40 . The buoy chamber body 10 includes a bottom plate 11 and a tubular shell 13 . The bottom plate 11 is connected to the tubular shell 13 and is provided with a first nozzle 13A opposite to the upper end of the tubular shell 13 . The bottom plate 11 has a first through hole 11A and a plurality of second through holes 11B. The upright tube 20 is fixed on the bottom plate 11 and has a second nozzle 20A and a third nozzle 20B. Wherein, the second nozzle 20A communicates with the first through hole 11A, and each second through hole 11B on the bottom plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com