Calibration method for micro-image

A technology of microscopic images and calibration methods, applied in electronic circuit testing, measuring devices, instruments, etc., can solve problems such as optical microscope image drift, and achieve the effect of solving microscopic image drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

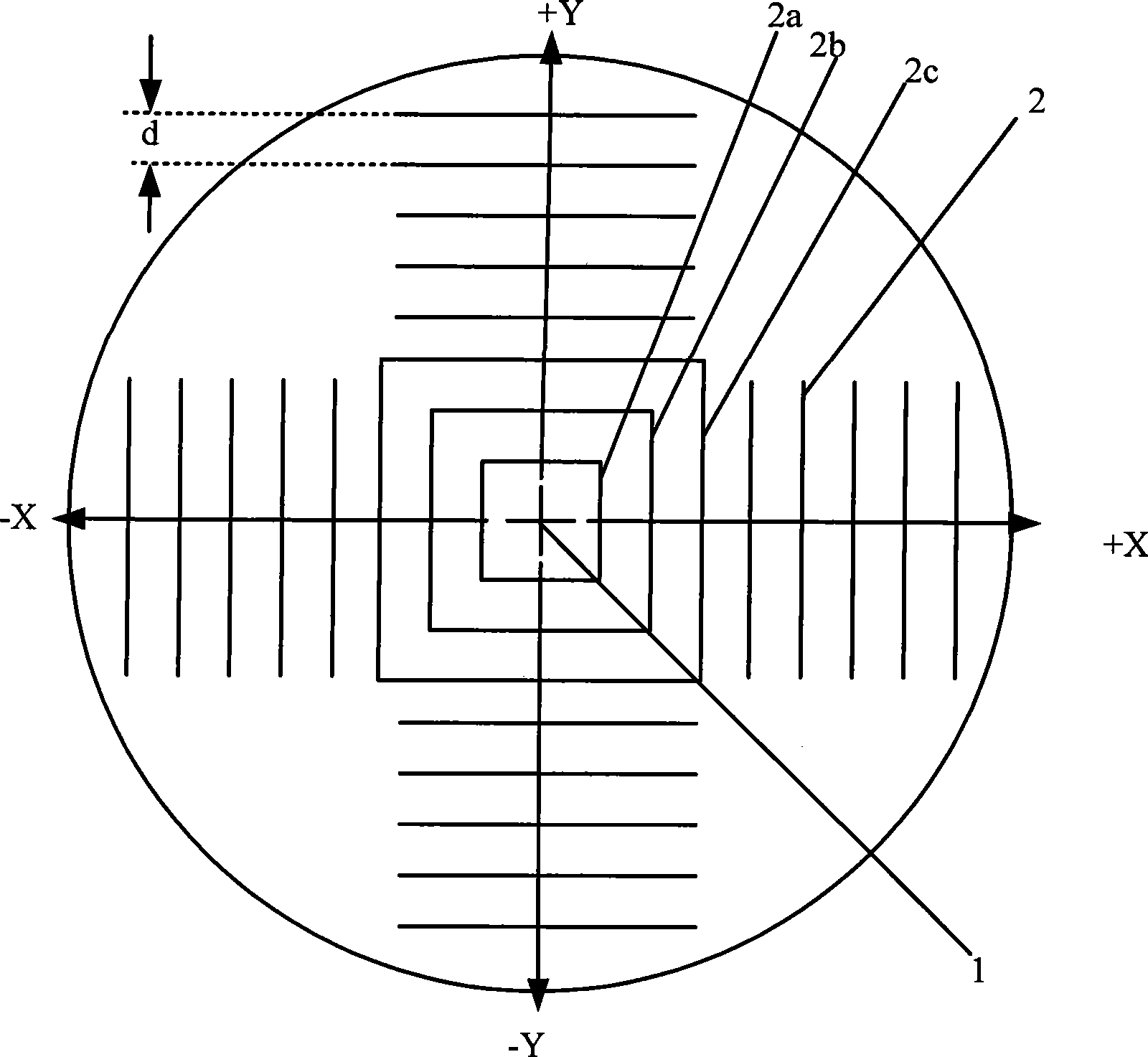

[0011] The microscopic image is the image of the test piece on the slide stage under the objective lens with a central mark of the optical microscope. The center of a conventional objective is marked with a cross. The calibration method includes step 1: providing a calibration sample with a scale mark and the same mark as the center mark of the objective lens at the center. see figure 1 Calibration sample image. Since the center of the optical microscope is currently marked as a cross, in order to facilitate subsequent alignment, the center of the calibration sample is also a cross 1, which corresponds to the cross in the center of the objective lens. Step 2: Put the calibration sample on the slide stage, and align the cross marked on the center of the objective lens of the optical microscope under a certain magnification with the center mark cross 1 on the calibration sample. At this time, the magnification of the optical microscope is usually selected as a lower magnifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com