Projection apparatus with cooling structure

A heat dissipation structure and projector technology, applied in the field of projectors, can solve the problems of shortening the service life of the projector and reducing the working efficiency of the projector, and achieve the effect of rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

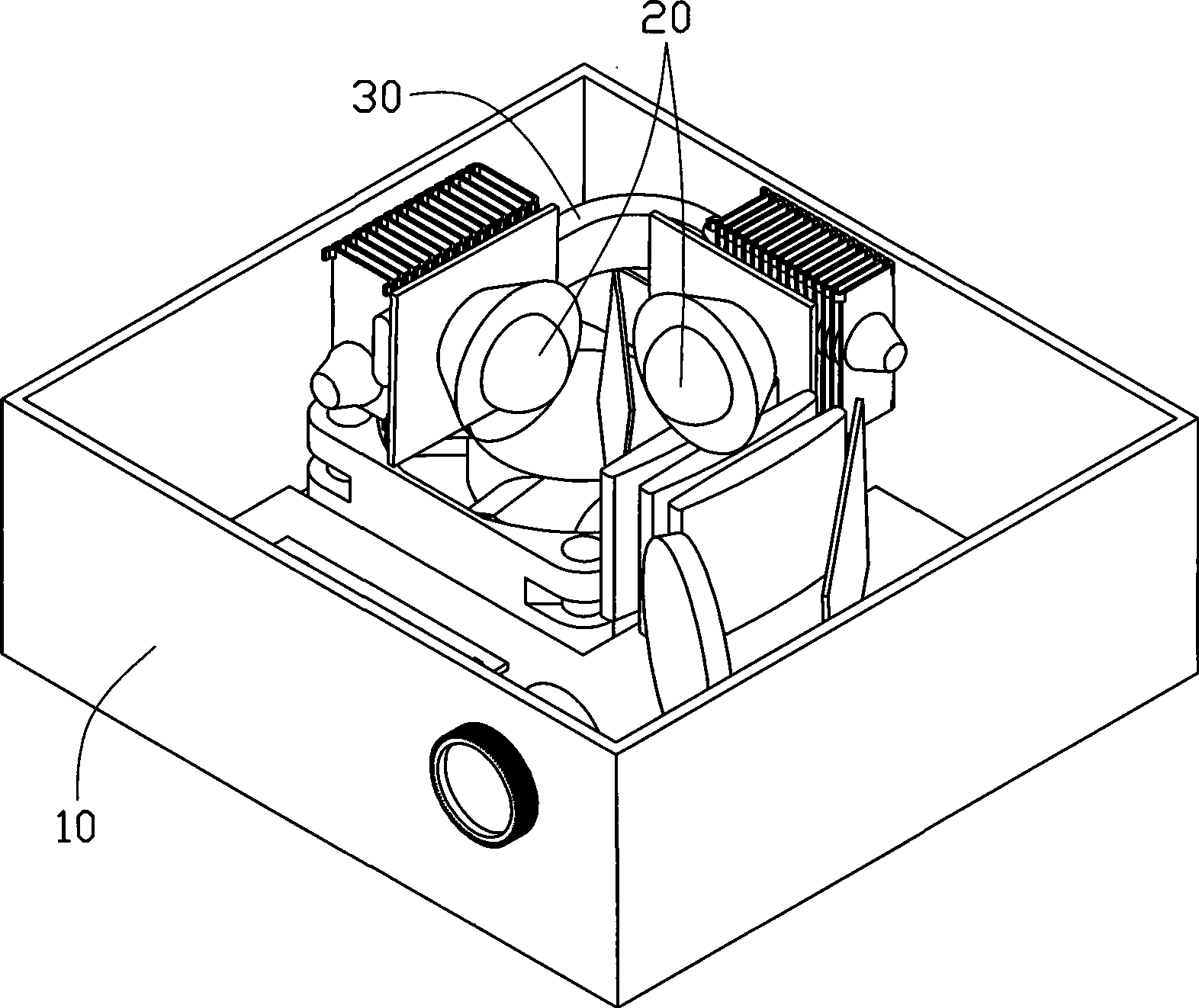

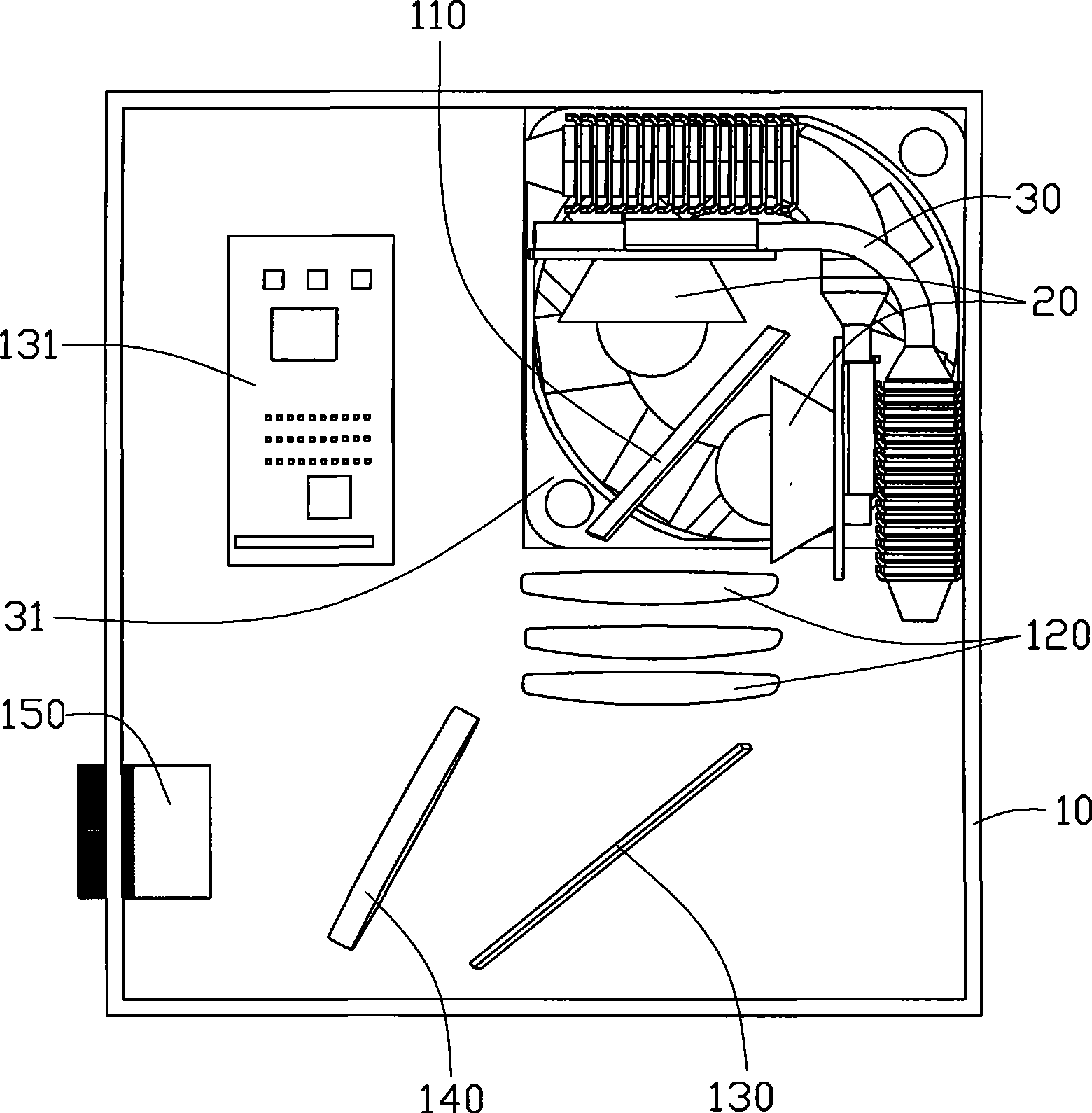

[0012] see figure 1 and figure 2 The projector with heat dissipation structure of the present invention includes a case 10 , two light sources 20 placed in the case 10 , and a heat dissipation structure 30 located in the case 10 and connected to the two light sources 20 .

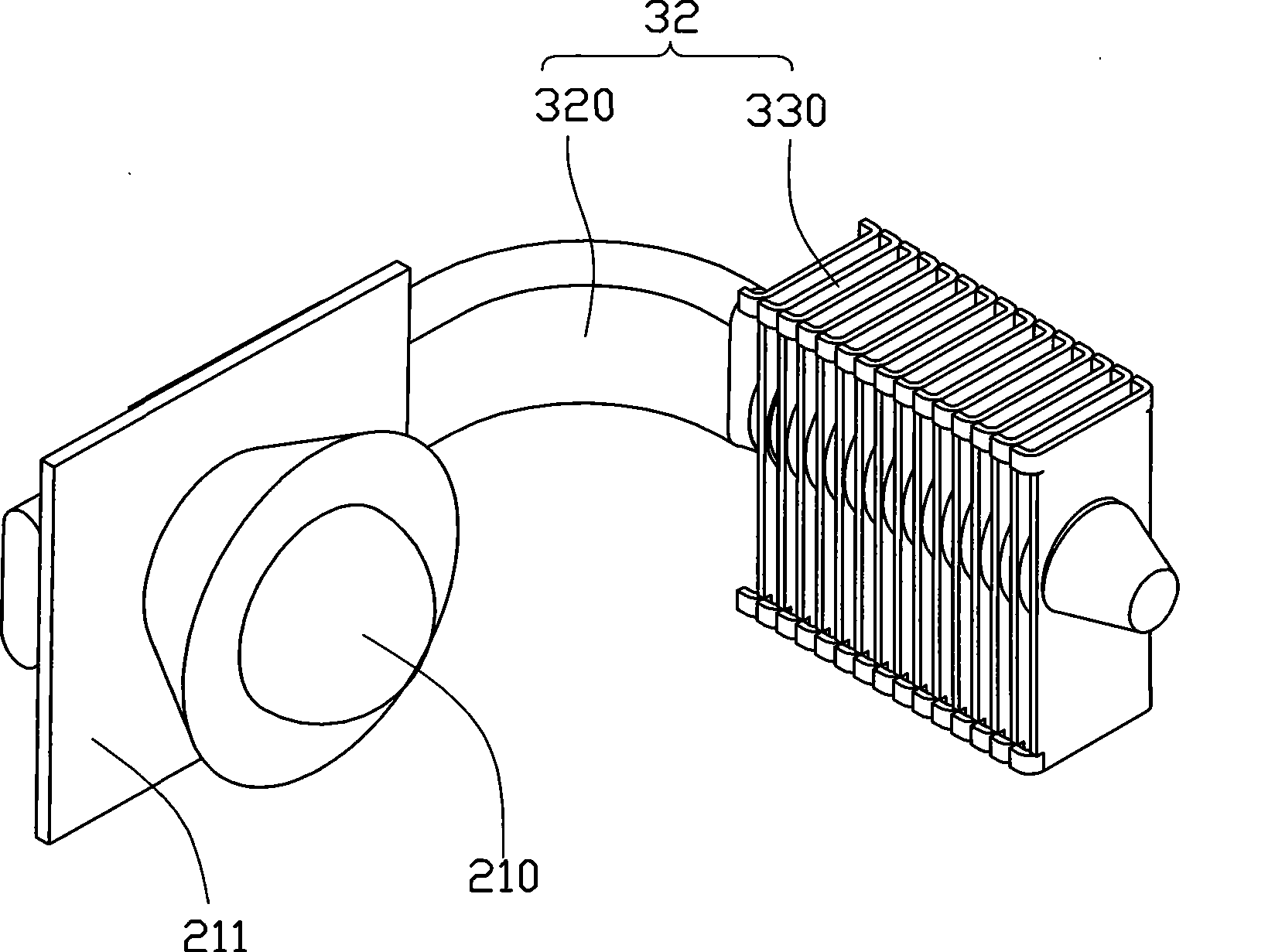

[0013] Please also see image 3 , the above-mentioned case 10 is a square casing, and the above-mentioned two light sources 20 are located at one side of the case 10 . In this embodiment, each light source 20 is a light emitting diode bulb, which includes a circuit board 211 and a light emitting diode 210 installed on the circuit board 211 . The circuit boards 211 of the two light sources 20 are perpendicular to each other in the housing 10 , and the light emitting directions of the two light emitting diodes 210 are vertical.

[0014] A first condenser mirror 110 is disposed between the two light sources 20 , and the light emitted by the two light sources 20 passes through the condenser mirror 110 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com