Fixed structure of hard disk die set

A technology for fixing structures and modules, applied in the direction of record carrier structural parts, instruments, data recording, etc., can solve the problems of disassembly and installation that take a lot of time and manpower, slow production speed, and disintegration of screw teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

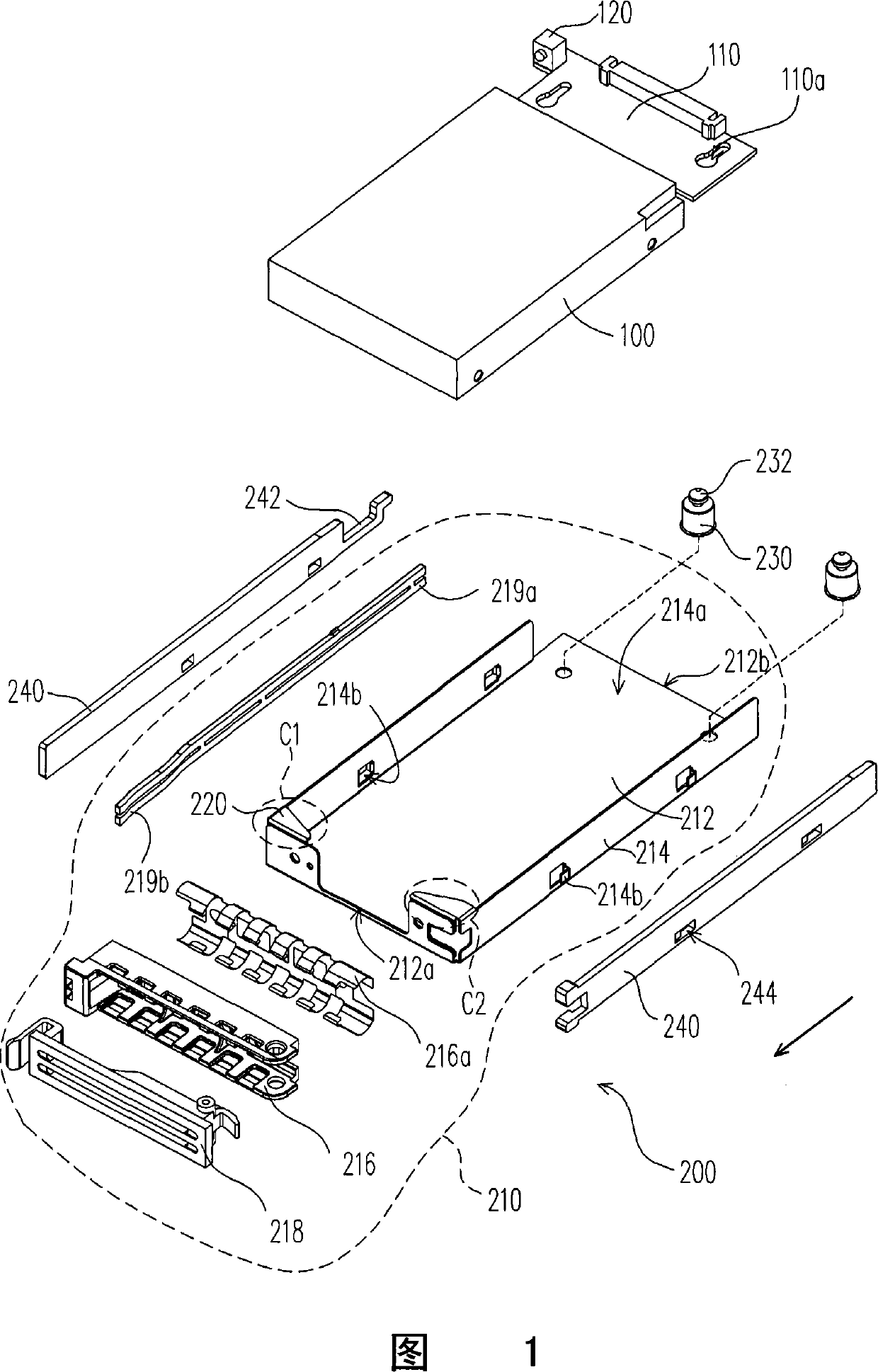

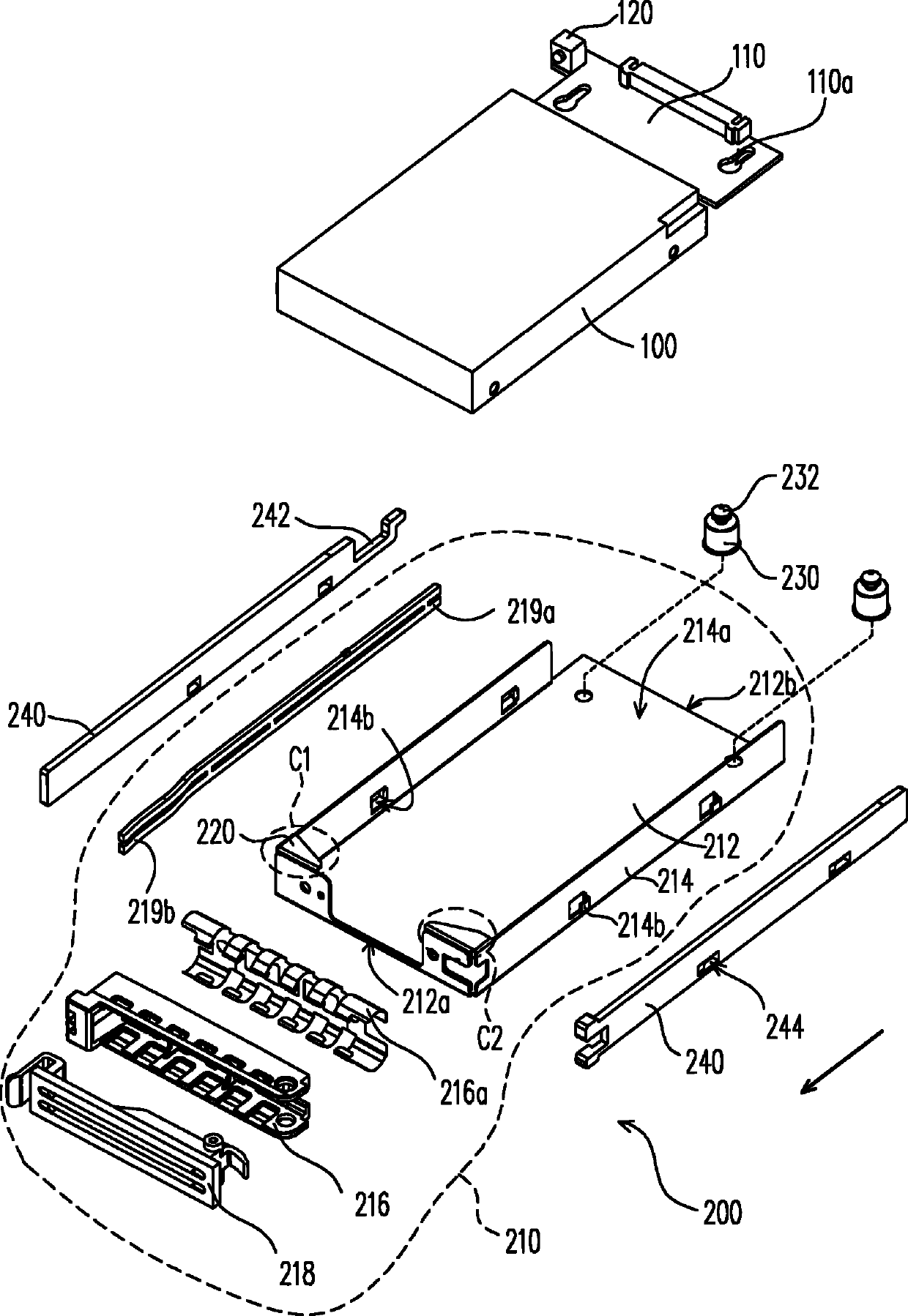

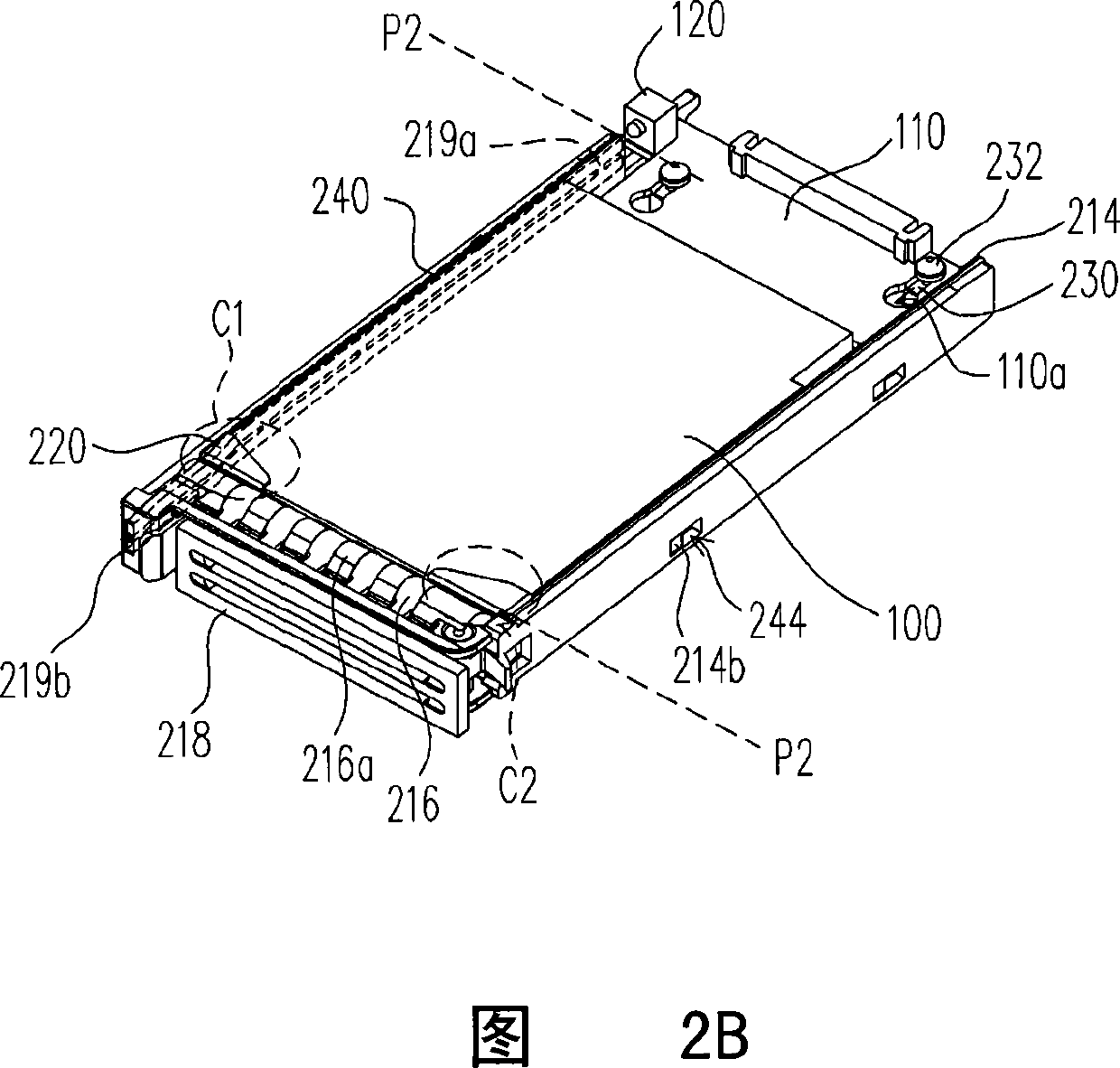

[0053] figure 1 It is an exploded schematic view of a fixed structure of a hard disk module according to an embodiment of the present invention. Please refer to figure 1 , the hard disk module 100 has a base plate 110 and at least one locking hole 110a opened in the base plate 110 ( figure 1 Only two are schematically shown in ), wherein the lock hole 110a is, for example, a gourd hole. The hard disk module fixing structure 200 includes a casing 210 , two corner fixing pieces 220 , at least one fixing post 230 and two rails 240 .

[0054] In detail, the casing 210 has a bottom plate 212 and a plurality of frames 214 ( figure 1 Only two are schematically shown in the figure), in this embodiment, the frame 214 is, for example, an L-shaped frame, and the bottom plate 212 and these frames 214 jointly define an accommodating space 214a. The bottom plate 212 has a first side 212a and a second side 212b opposite to the first side 212a, and the hard disk module 100 enters the acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com