Heat dissipation chassis and its printed board assembly

A technology for printed boards and components, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problems of complex heat pipe fixing structure and high cost, and achieve fast, efficient heat conduction and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

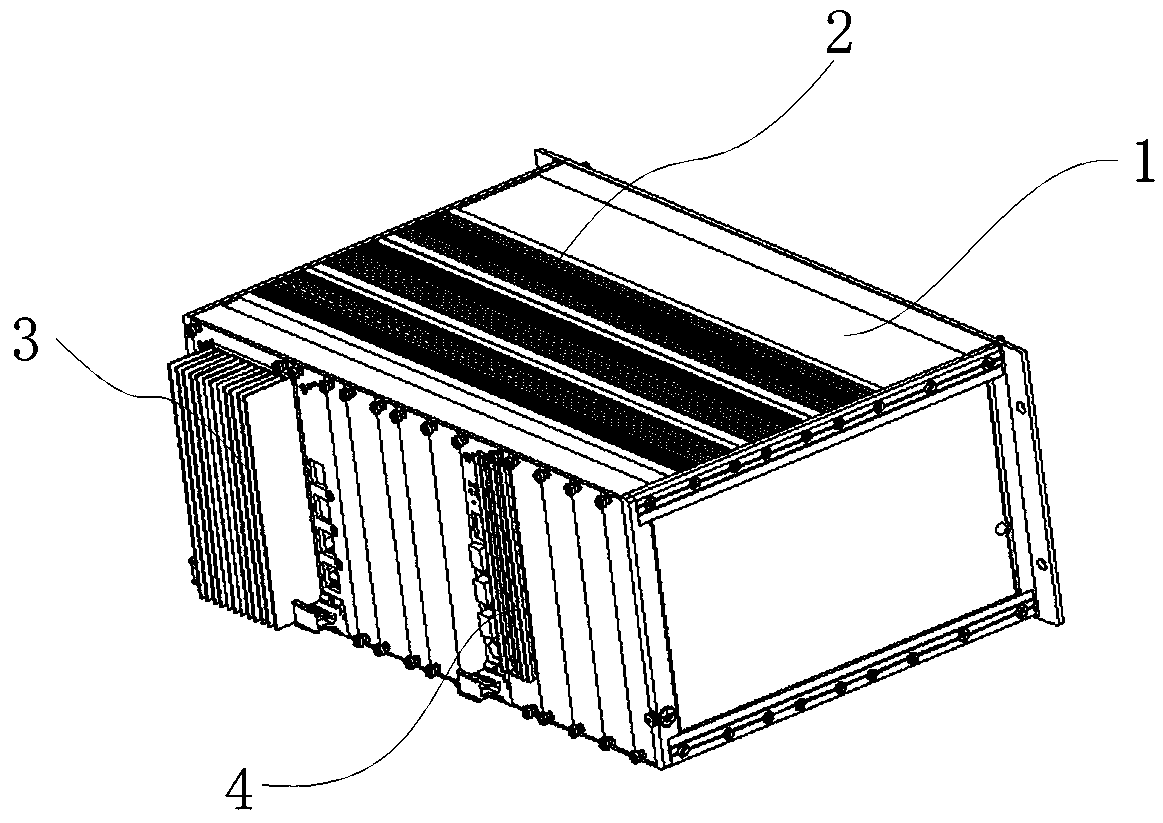

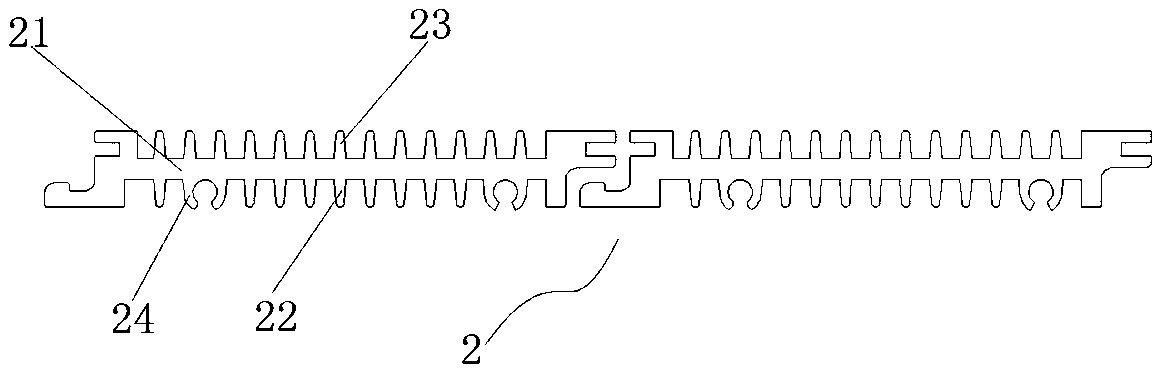

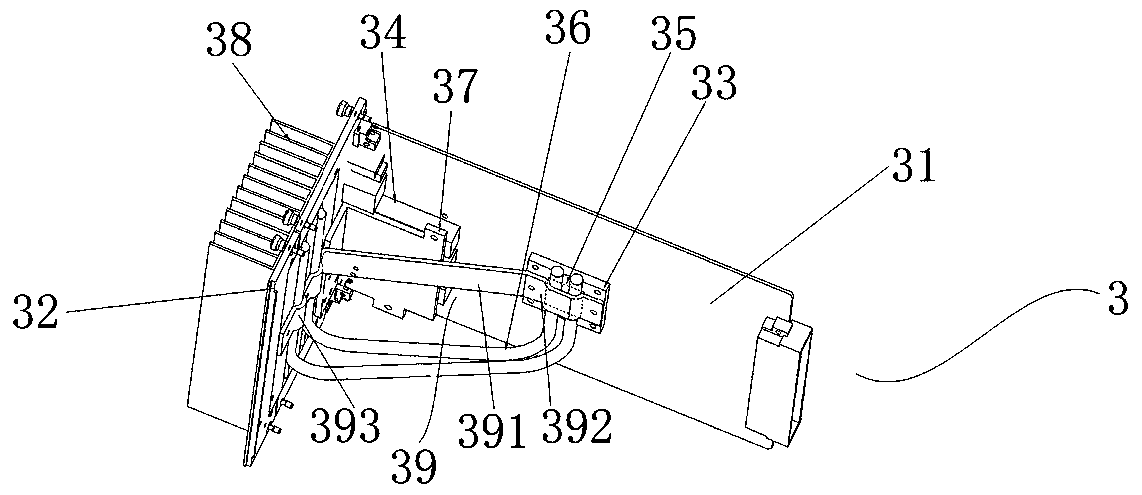

[0027] The specific embodiment of the cooling cabinet of the present invention, as Figure 1 to Figure 6 As shown, in order to conduct the heat in the cooling case to the outside of the cooling case in time, the present invention formulates three cooling methods. The first type is to install the cover plate radiator 2 on the cover plate, the second type is for the heat dissipation of the first plug-in 3 with relatively large heat generation, and the third type is for the heat dissipation of the second plug-in 4 with small heat generation.

[0028] The first type is to provide a through hole on the cover plate 1 of the cooling case, and set a cover plate radiator 2 in the through hole. The cover plate radiator 2 includes a body 21, the inner side of the body 21 is located in the cooling case, and the outer side is located outside the cooling case , the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com