A method, lifting device and arrangement for replacing a fabric in a web forming machine and a corresponding web forming machine

A technology for forming machines and fabrics, used in textiles and papermaking, paper machines, wet end of paper machines, etc., can solve problems such as damage to fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

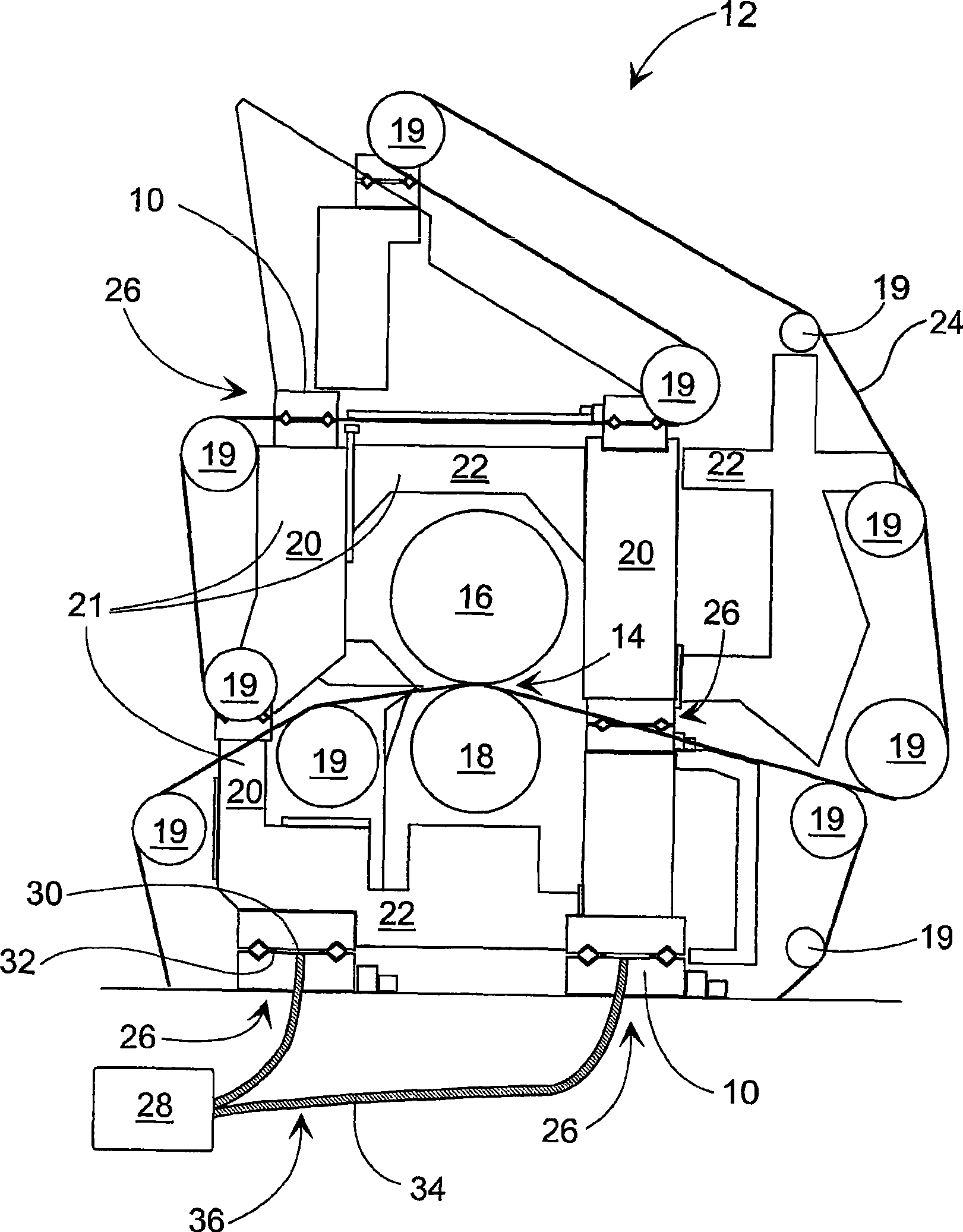

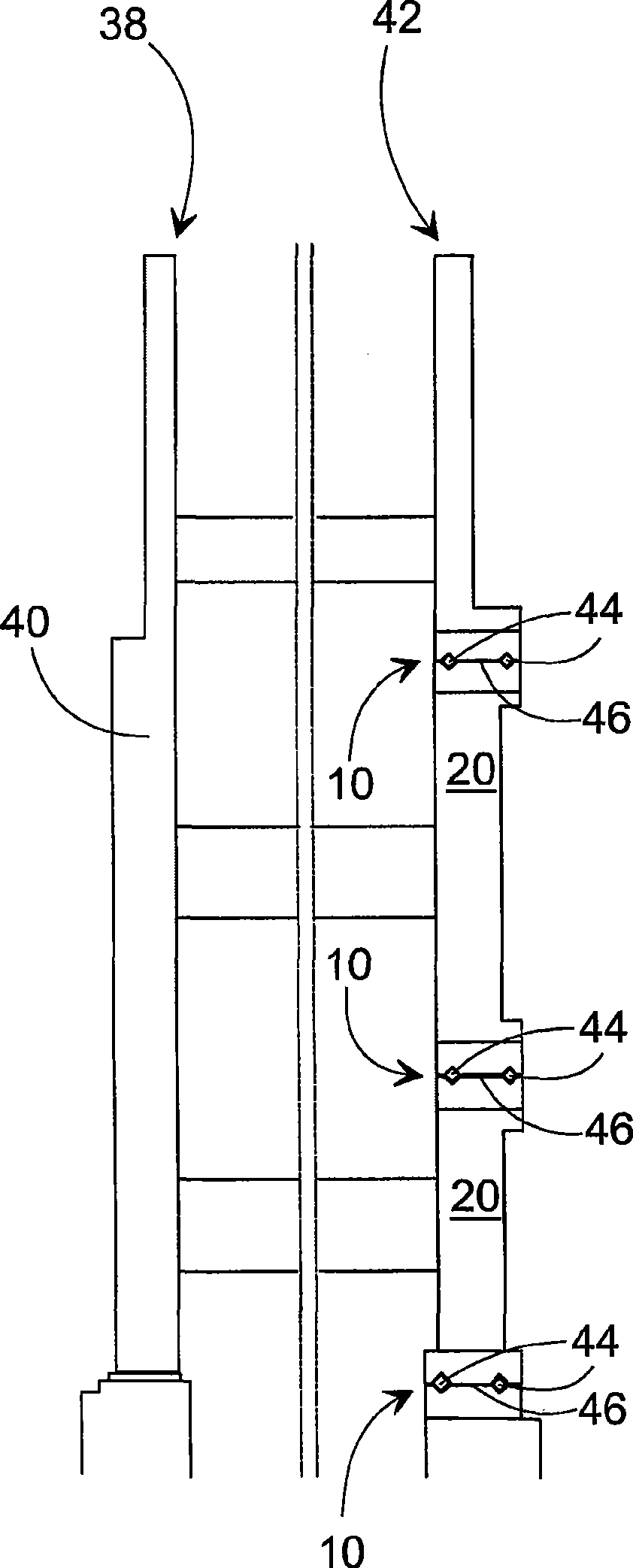

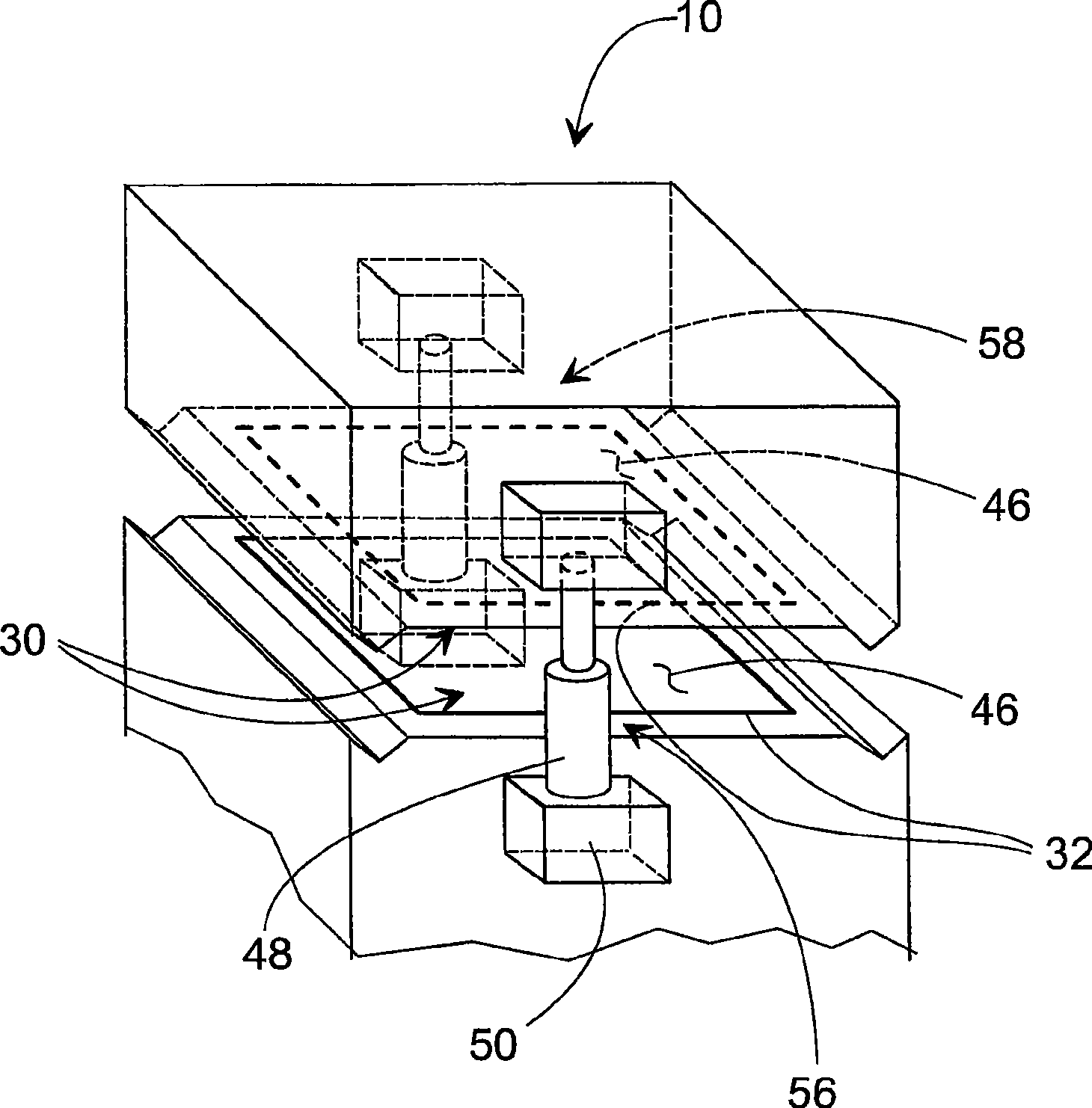

[0020] figure 1 The press section 12 of a web forming machine, such as a paper or board machine, is depicted, the figure showing a longitudinal section of the web forming machine. A nip 14 is formed between a top roll 16 and a bottom roll 18 . figure 1 The cross-section of the machine is taken approximately in the middle of the machine and is a view from the back side, in this case the front side beam 21 consisting of a beam 20 and a horizontal beam 22 is partially hidden behind the rollers . Gravity is notably supported by vertical beams, which may be inclined. For beams supported in the direction of gravity, the term "vertical beam" is used, but this term is not intended to limit the shape or position of the beam. The fabric 24 in the press section 12 is supported in endless form by the rolls 16,18,19. These rollers 16 , 18 , 19 are in turn supported by beams 21 , or more precisely, by a frame consisting of vertical beams 20 and horizontal beams 22 . An openable interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com