Safety system for motor driven swing door leaf

A safety system, motor-driven technology, applied in the field of safety systems, can solve problems such as large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

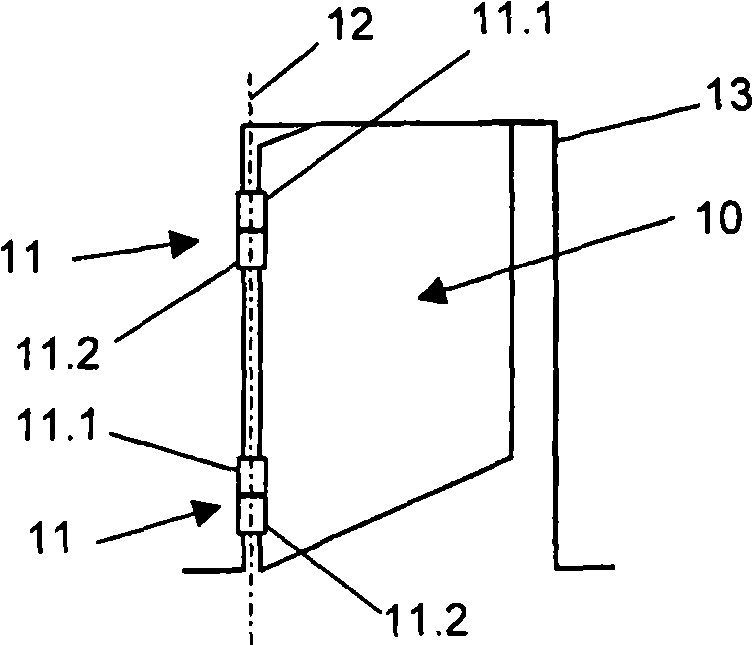

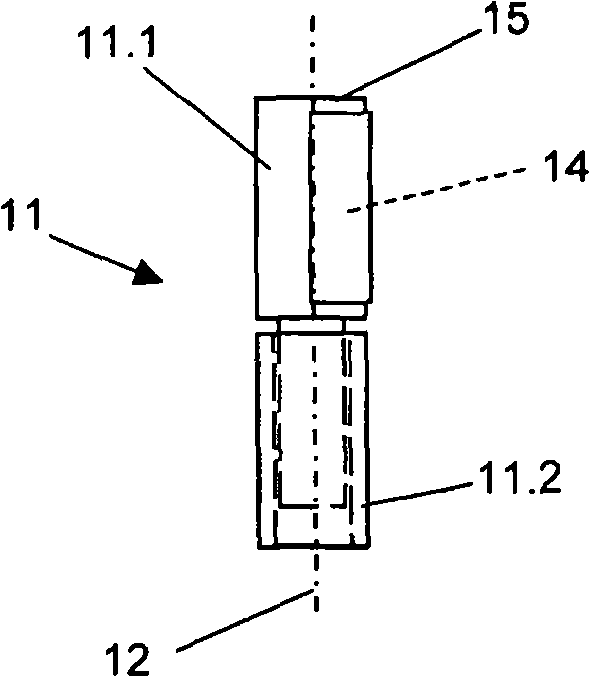

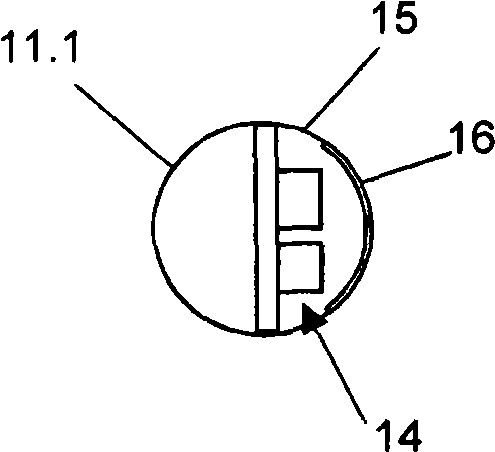

[0024] figure 1 The illustrated swing door leaf 10 is rotatably supported on the door frame 13 adjacent to the attached rectangular door hole via two hinge joints 11 on the left narrow side of the figure. The two hinge joints 11 are usually arranged on the door frame 13 staggered in height, and are respectively formed by two hollow cylindrically wound end regions of the door hinge. The upper door hinges of two hinge joints 11 are fixed on the swing door leaf 10 and thus form the upper sleeve-shaped hinge part 11.1, while the lower door hinge is fixed to the door frame 13 and forms the lower sleeve. A cylindrical hinge part 11.2 with the same diameter. In order to realize the accurate rotation support of the swing door leaf 10 corresponding to the axis of rotation 12, a round shaft pin protrudes from the lower end of the hinge part 11.1, and the shaft pin is inserted into the hole of the hinge part 11.2 located axially downward with a certain gap. . In addition, the swing door le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com