Mophead with a sheet of mop material forming a splayable skirt

A technology of mop material and mop head, applied in the field of mop head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

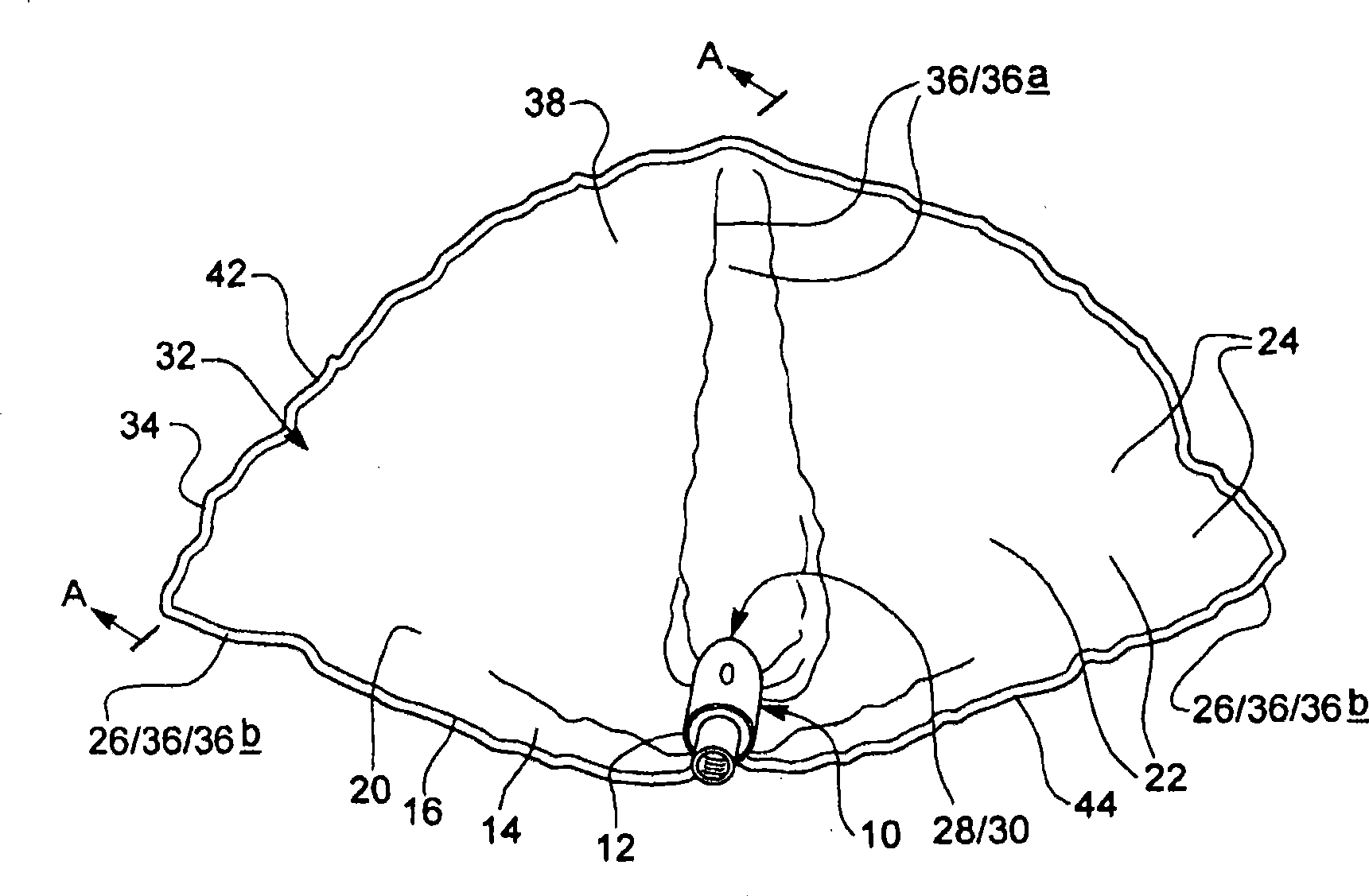

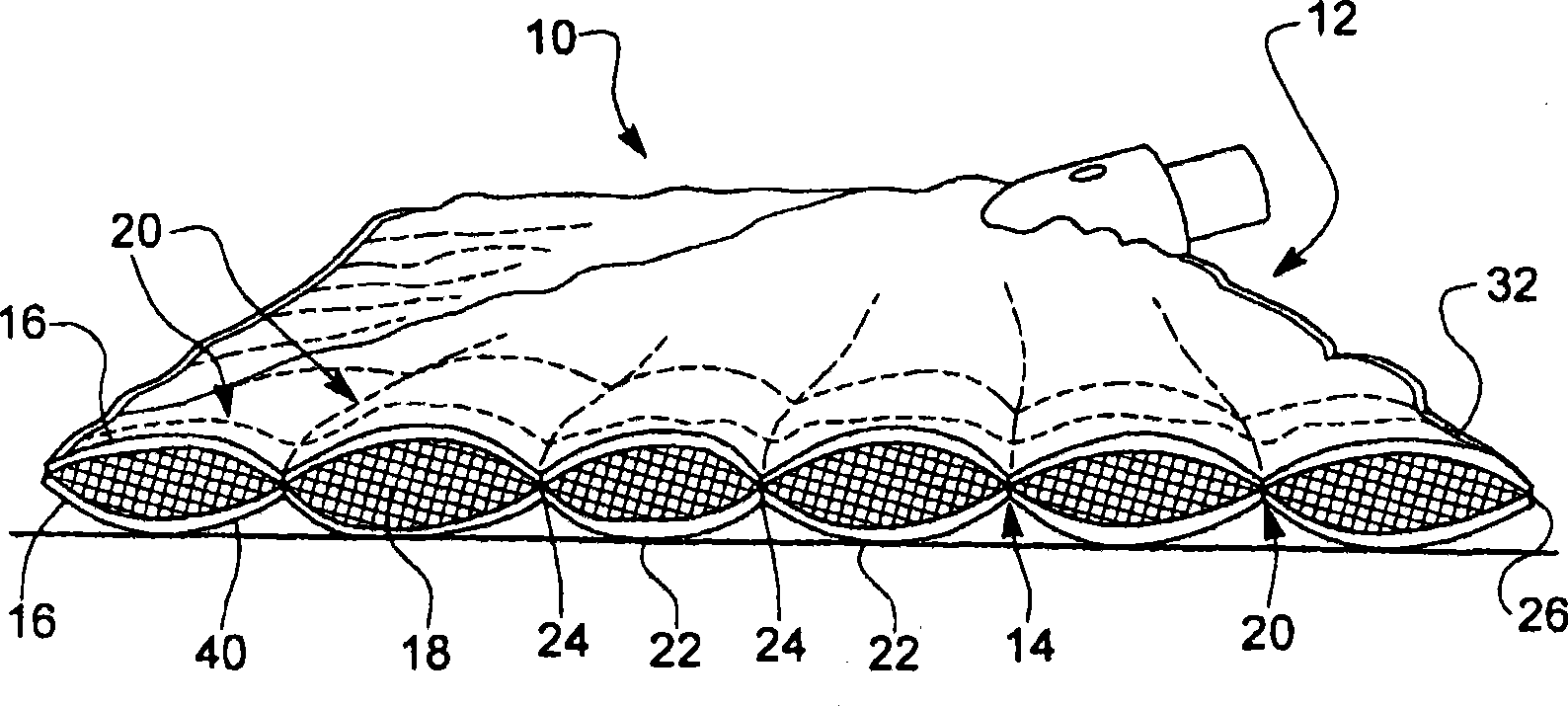

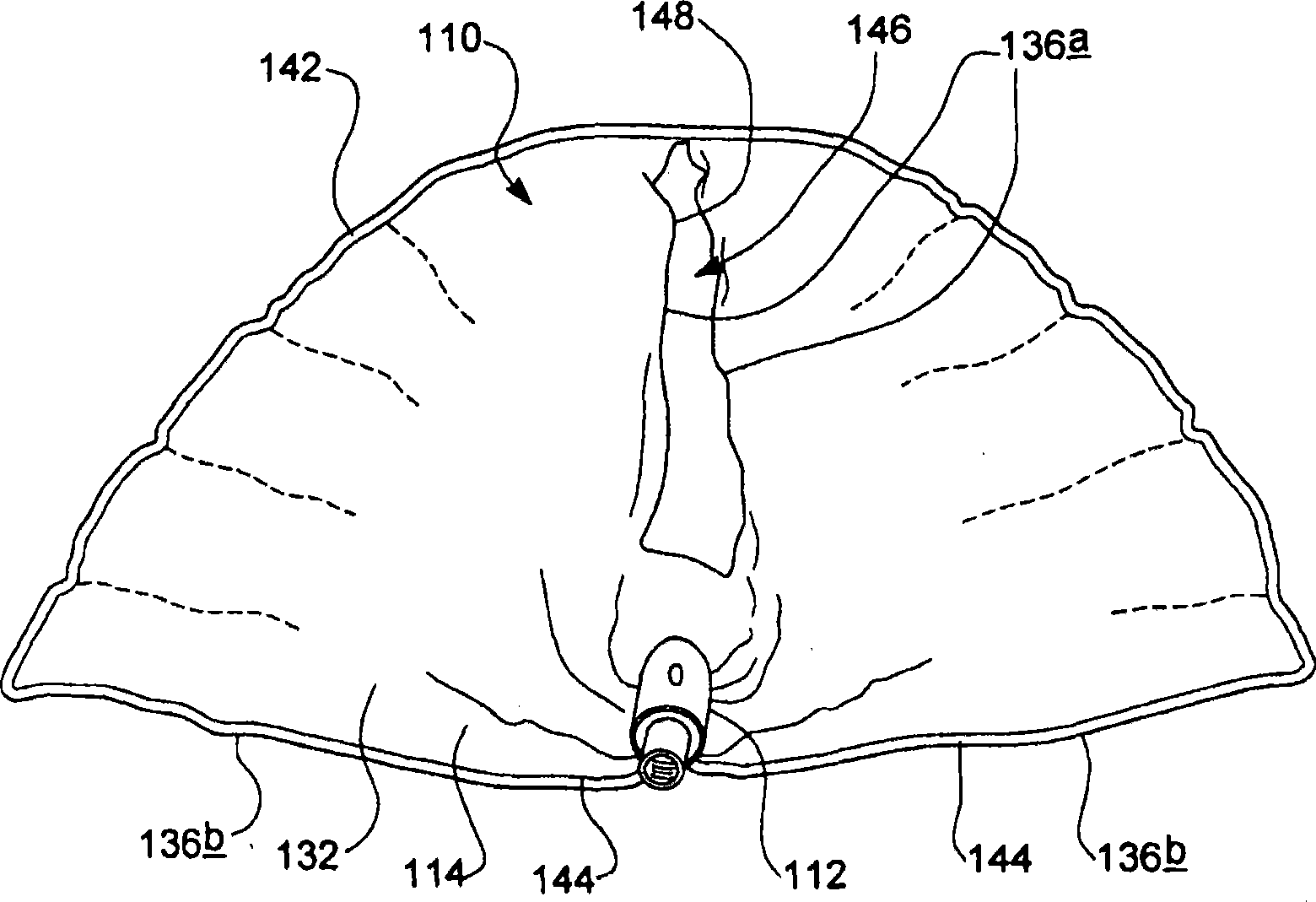

[0020] First refer to the attached figure 1 and figure 2 , which shows a mop head 10 comprising a mop material holder 12 and a mop material sheet 14 . Retainer 12 is a well known device and comes in a variety of different sizes from elongated to round. The sheet of mop material 14 is generally in the form of a continuous carpet, typically formed from a plurality of interconnected woven or nonwoven flexible layers (typically fabrics). In this embodiment, the sheet 14 includes two outer absorbable layers 16 and an inner absorbable fill layer 18 sandwiched between the two outer layers 16 .

[0021] The outer layer 16 is preferably made of a porous material having small pores, and the inner packing layer 18 is preferably a loosely woven packing. The outer layer 16 and inner layer 18 may be constructed of any suitable material, such as recycled waste material or purpose-made material.

[0022] The outer layer 16 and inner padding layer 18 are joined together via one or more fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com