Unloading device for ship

A unloading device and marine technology, applied in the field of marine equipment, can solve problems such as low loading and unloading efficiency, and achieve the effects of improving efficiency, reducing sticky materials, and reducing delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described now in conjunction with accompanying drawing.

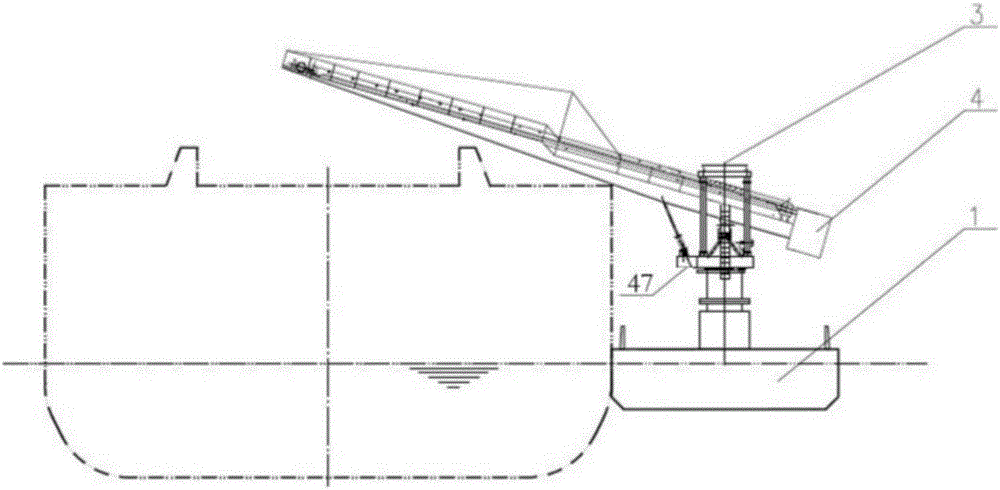

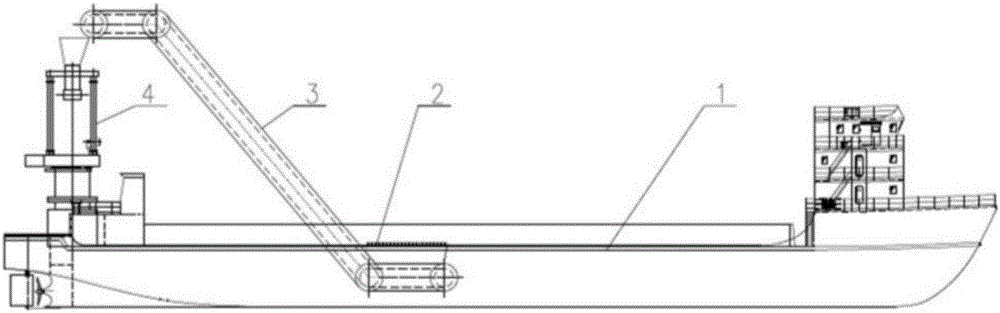

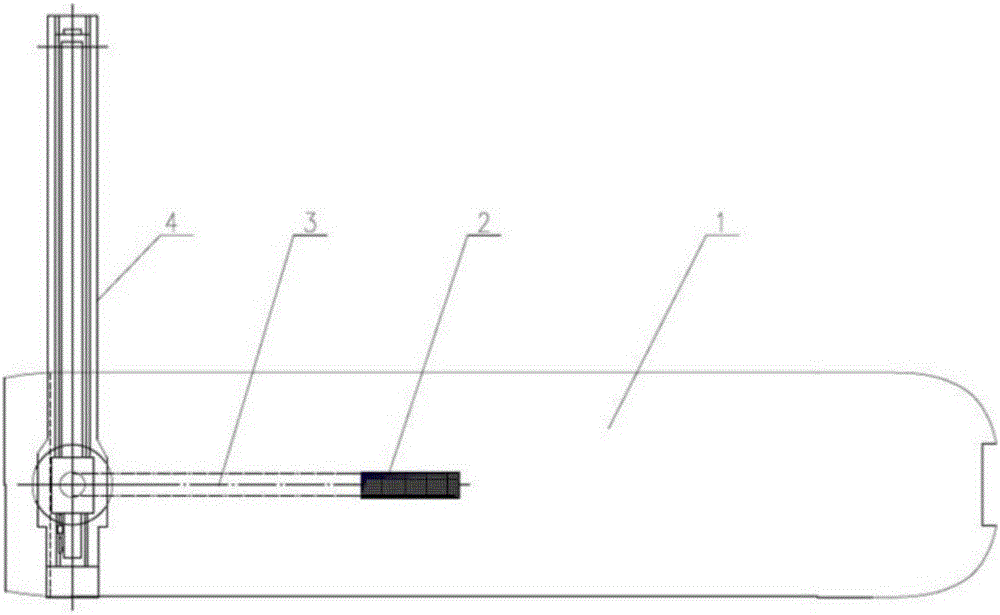

[0023] see figure 2 , image 3 , figure 2 , image 3 What is shown is an embodiment of the present invention, including a ship body 1, which includes a powered barge. Among them, the power and equipment devices are concentrated at the tail, that is, the tail type is adopted, which can make the relatively square hull in the middle be used to set the receiving bin 2 for loading bulk cargo, so as to improve the loading and unloading efficiency; the length of the shafting can be reduced, and the Propulsion efficiency; avoid setting shaft tunnel cabins and reduce manufacturing costs.

[0024] The mouth of the storage bin 2 is flush with the upper deck of the ship body 1, and is provided with a fixed grid screen, which can prevent large pieces of material from entering the equipment of the present invention.

[0025] An unloader 4 is arranged at the midline of the upper deck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com