Computer flat knitting machine

A computerized flat knitting machine and needle board technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as inaccurate selection of stitches, unreliable push needles, and complex processing of overall castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

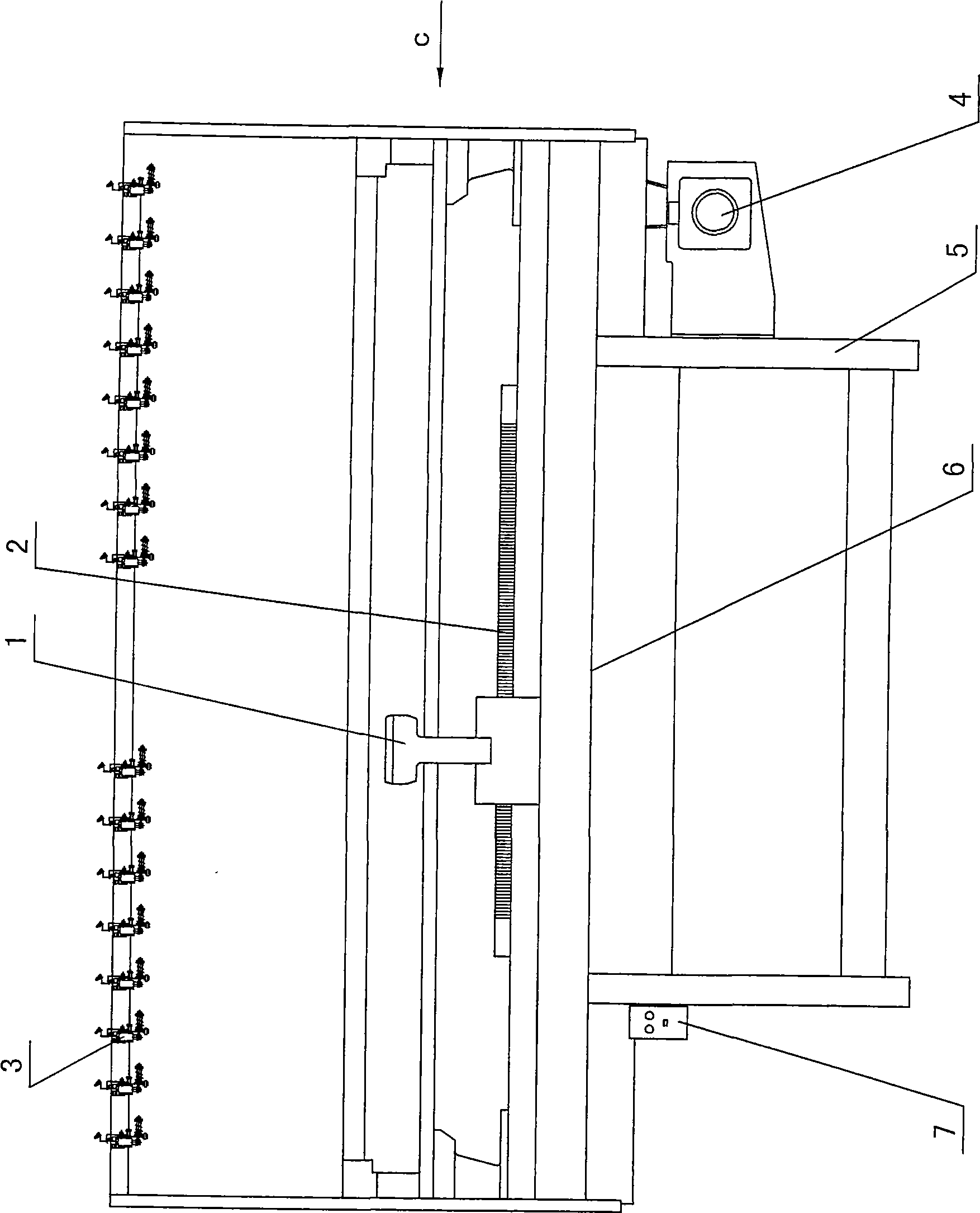

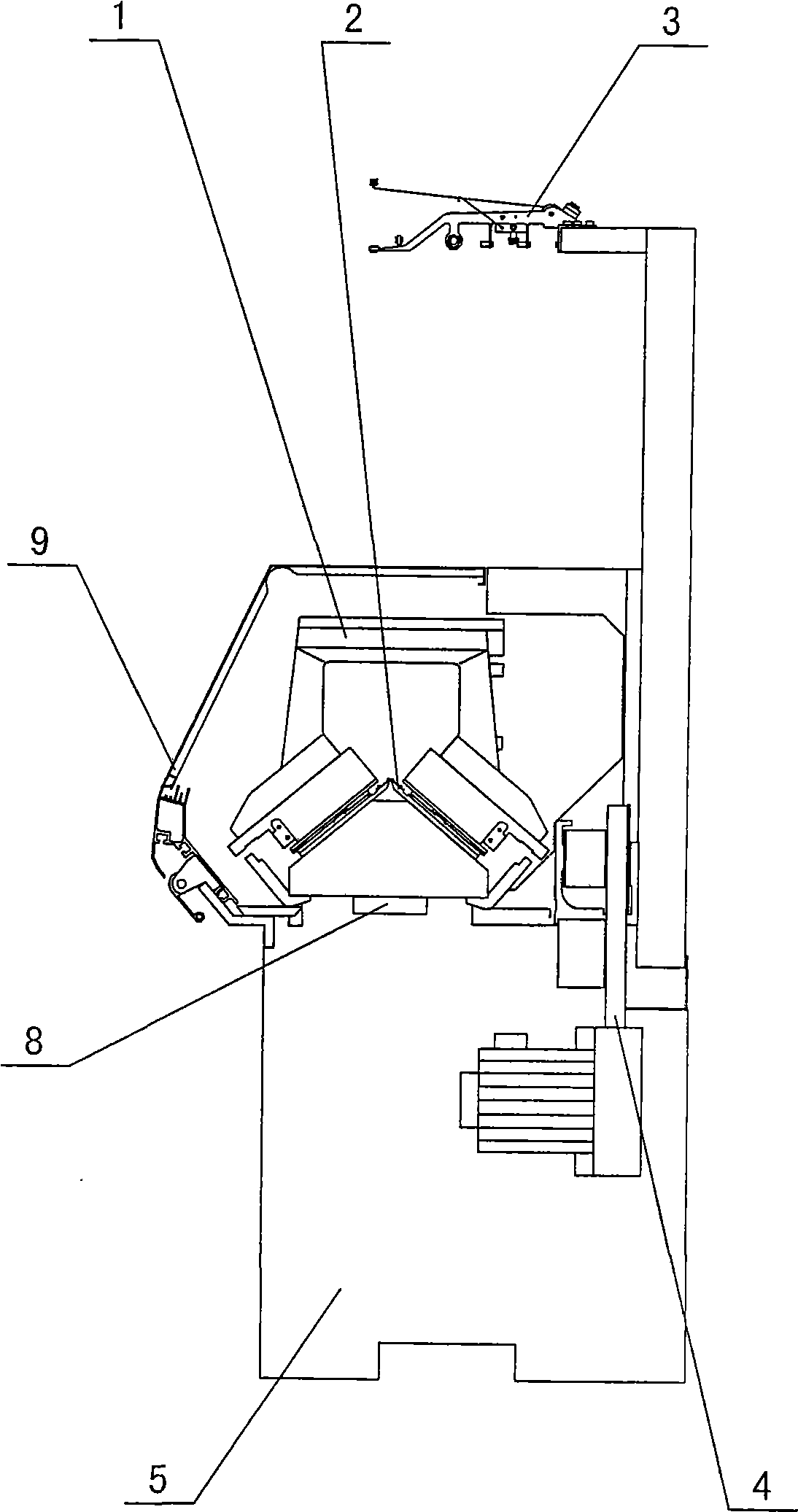

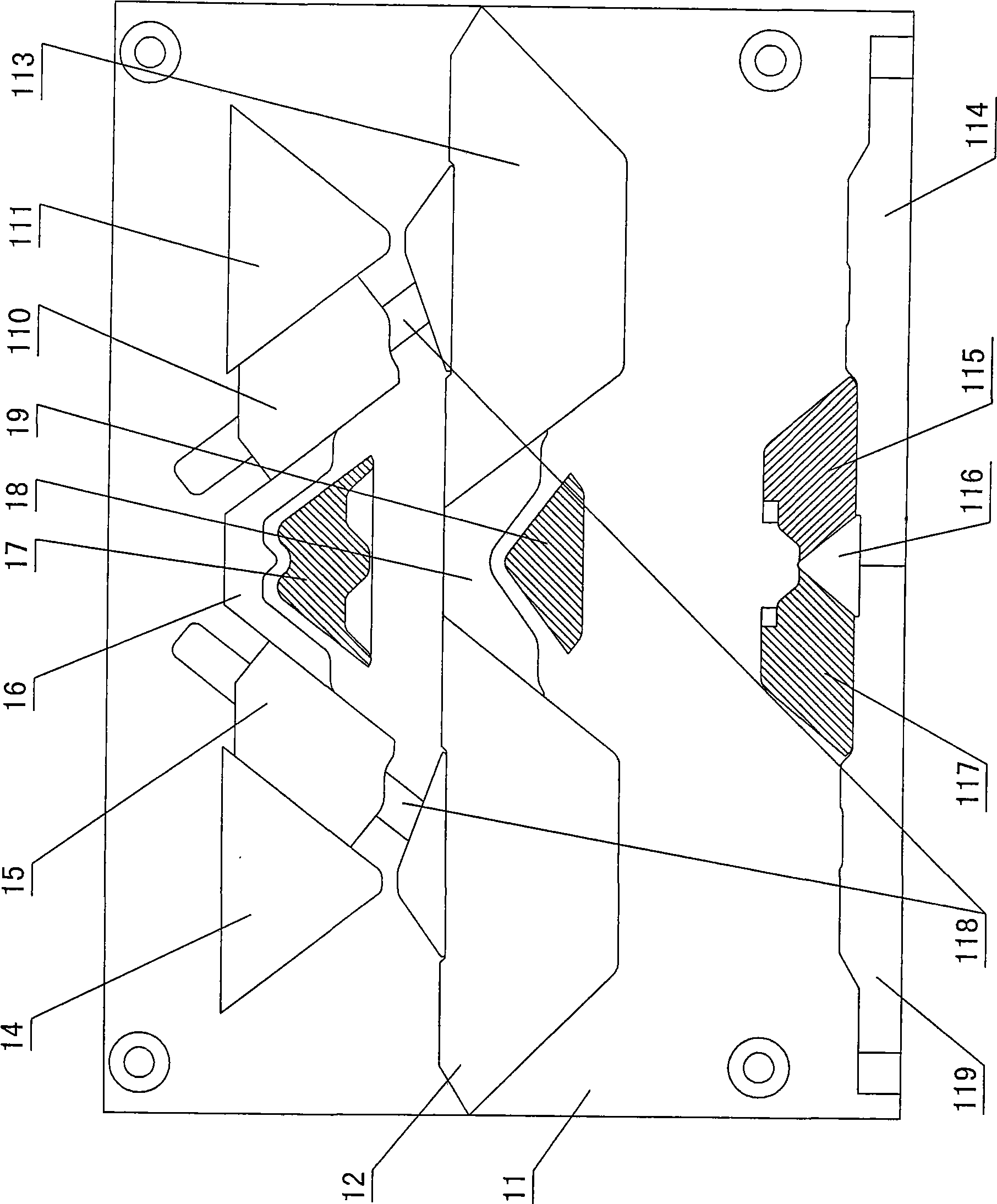

[0015] The invention relates to a computerized flat knitting machine, such as figure 1 — Figure 8 As shown, it includes machine head installation 1, needle plate installation 2, creel installation 3, transmission section installation 4, frame installation 5, roller installation 6, electric control installation 7, bed shifting installation 8 and The outer cover part is composed of 9, and the machine head device 1 includes a knitting system and a needle transfer system arranged on a triangular bottom plate 11. The needle board part includes a needle selection pin 22, a needle board 21 and a knitting needle Needle 23, the selection pin pushes the knitting needle, and the selection pin 22 is formed with a push needle butt 211 and a selection needle butt 212, the push needle butt is in contact with the push needle cam 204, and the selection needle butt is in contact with the needle selection blade 205 , the frame part includes a left wallboard 101, a right wallboard 104, a beam 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap