Front and rear regulation structure of hinge for furniture

A technology for front and rear adjustment and furniture, which is used in building structures, door/window accessories, folding panels, etc., can solve the problems of lack of upper and lower limits, low structural rigidity, complicated installation, etc., to achieve stable structure and long service life. , to avoid the effects of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

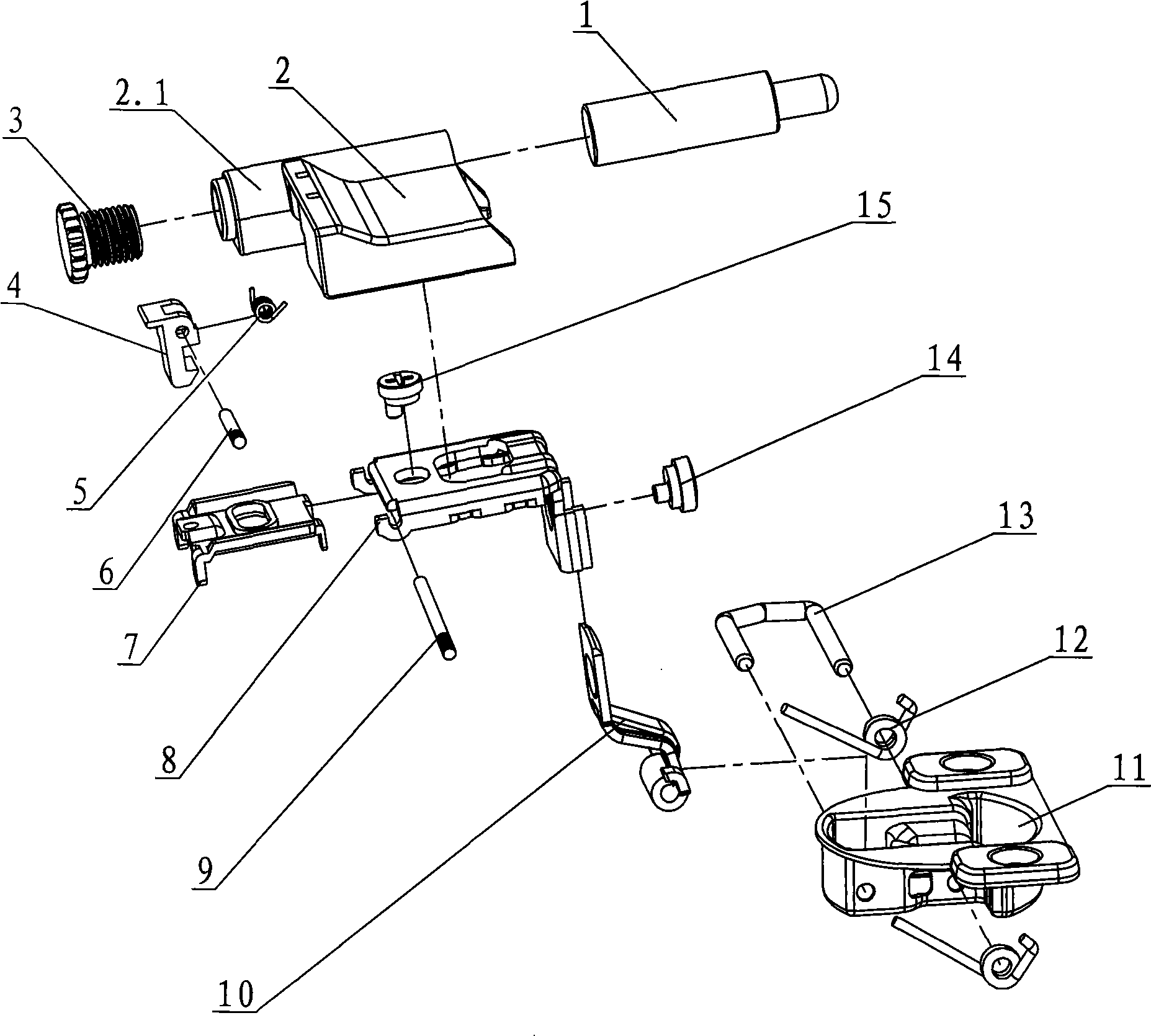

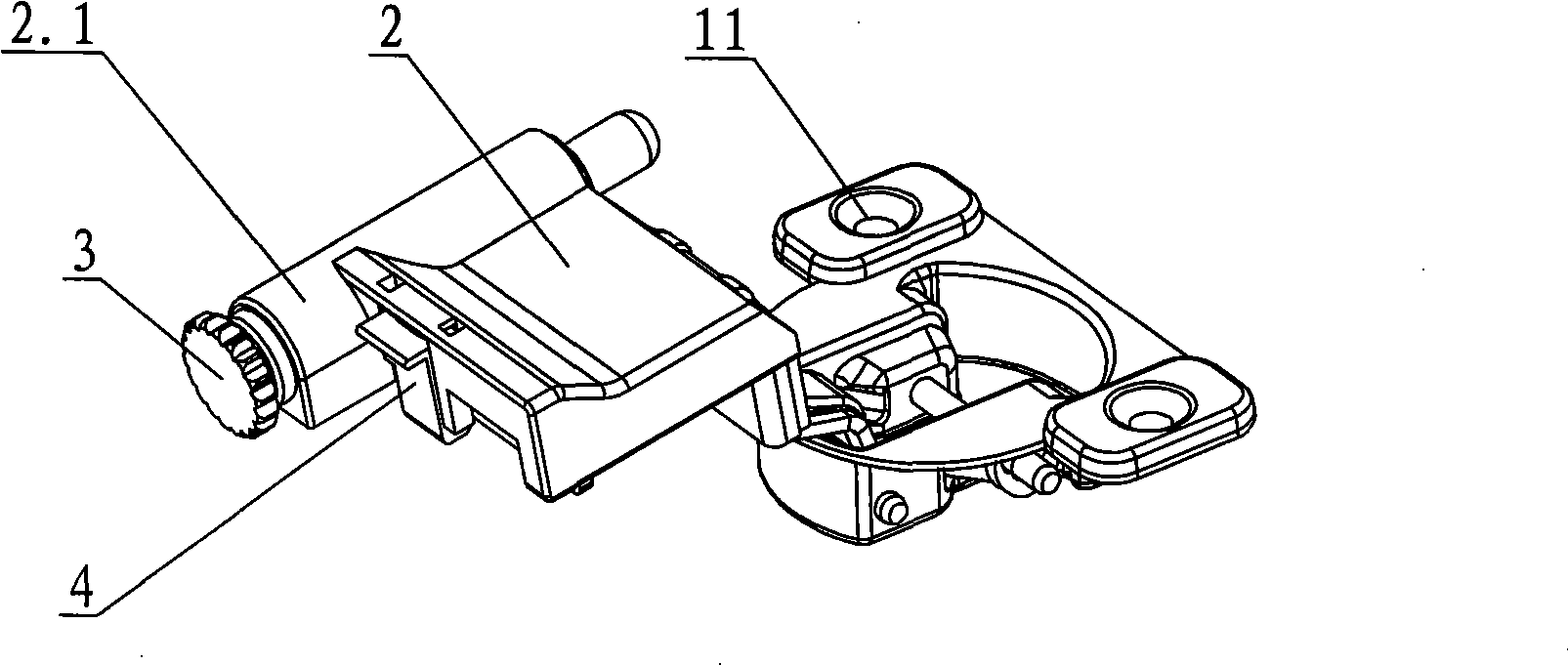

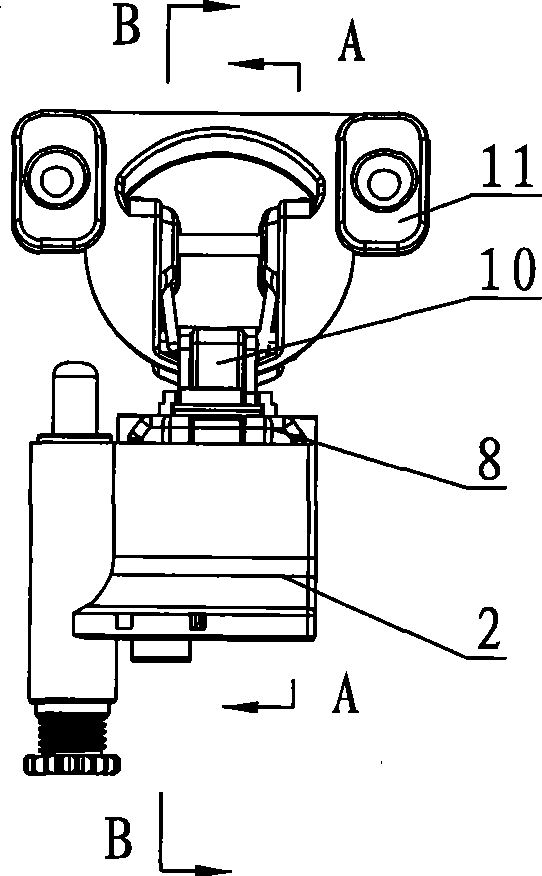

[0036] see Figure 1-Figure 14 , the front and rear adjustment structure of the furniture hinge, including the base 7 connected with the furniture main body 17 and the hinge cup seat 11 hinged with the support arm 10 through the U-shaped pin 13 and the second torsion spring 12 arranged on the left and right sides of the hinge cup seat 11, The base is connected with the support arm through the adjustment cover 8, and a buffer seat 2 is also arranged above the adjustment cover, and the hinge cup seat is arranged on the furniture door body 18, and the two sides of the rear end of the adjustment cover 8 are connected by pins 9, and the buffer The seat 2 is provided with a pull button 4 corresponding to the pin shaft 9, which is fastened with the pin shaft to position the buffer seat perpendicular to the direction of the adjustment cover.

[0037] see Figure 9-Figure 11 , the adjusting cover plate 8 is stamped and formed by sheet metal, the end face is arched, there are notches 8...

no. 2 example

[0042] see Figure 15 , the upper and lower sides of the buffer seat 22 rear end corresponding pins are provided with front and rear limit grooves 22.1 that are upside down U-shaped, connected with the pin 9, the two ends of the pin extend out of the buffer seat up and down both sides and are riveted with it. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0044] see Figure 16 with Figure 17 , the buffer seat 32 is a square cover shape, and the upper and lower side inner walls are provided with ribs 32.1, and the corresponding ribs on the upper and lower side inner walls of the adjustment cover plate are provided with slots 28.2 to connect with the ribs of the buffer seat to realize front and rear spacing. The buffer seat 32 is arranged outside the adjustment cover plate 28, the side part is provided with a buffer connecting cylinder 32.6, the inner top surface is provided with a positioning bump 32.2 connected with the top surface of the adjustment cover plate 28, and the rear end is also provided with a pull button corresponding to the pull button. Place cavity 32.5. Buffer seat 2 front end upper and lower sides corresponding adjustment cover plate 28 gap is provided with buckle block 32.3, and the rear end also stretches out front limit baffle 32.4 toward adjustment cover plate direction, joins with bearing pin and adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com