Non-exciting shunting switch convenient for shifting

A tap changer and excitation technology, applied in the direction of inductance/transformer/magnet manufacturing, transformers, electrical components, etc., can solve the problems of high spindle rigidity, large contact surface wear, and increased operating torque to achieve enhanced stability, Effects of stable contact and overall torque reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

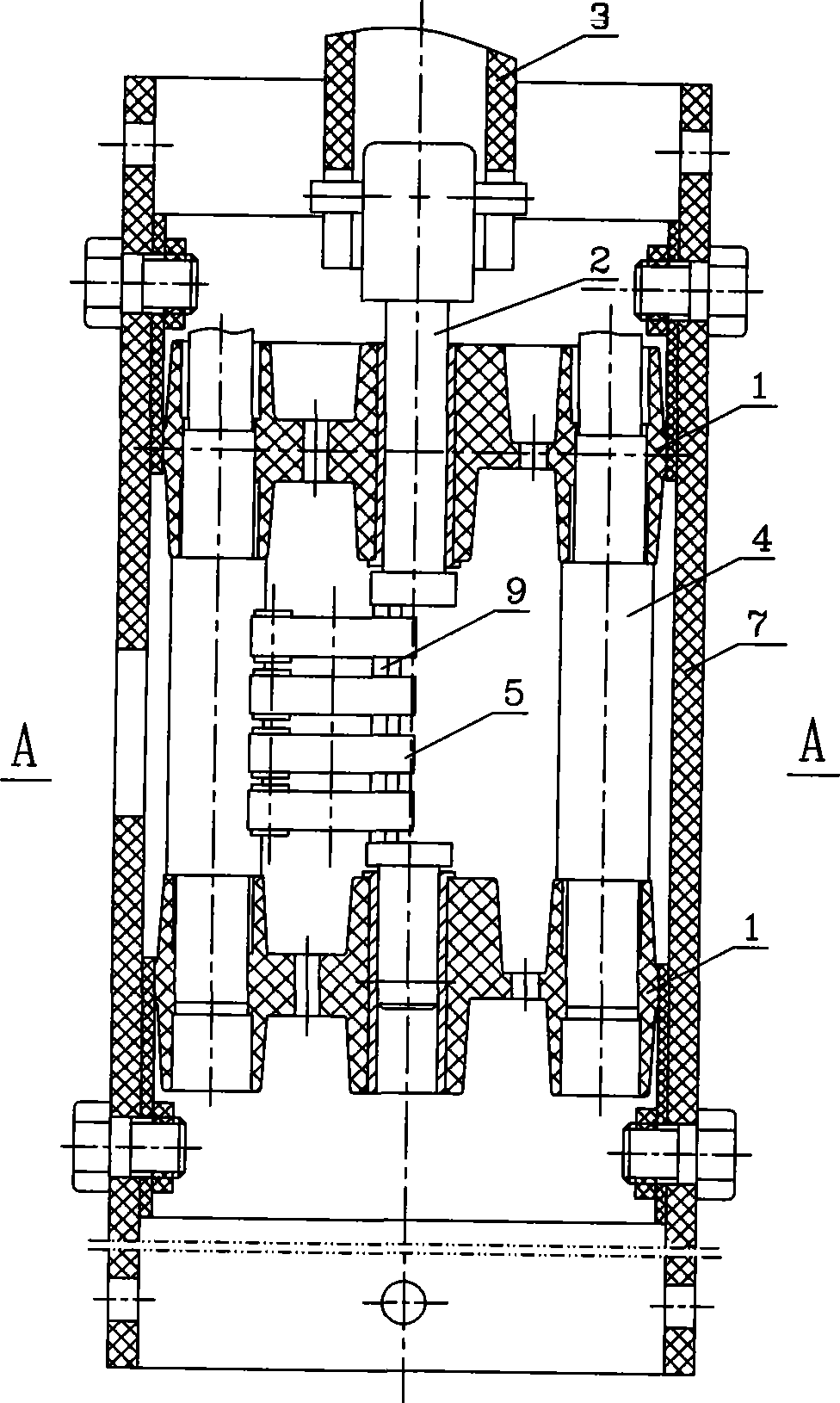

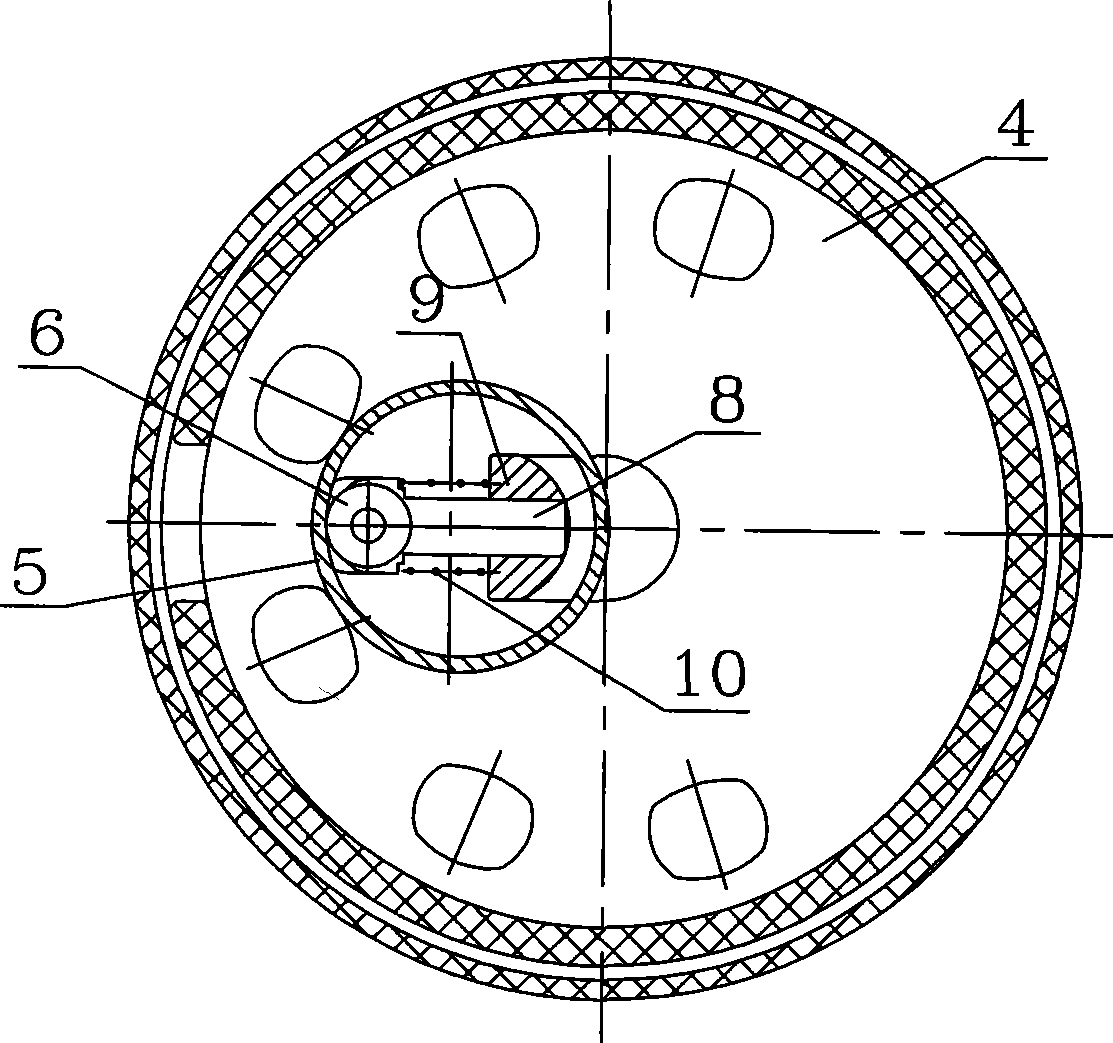

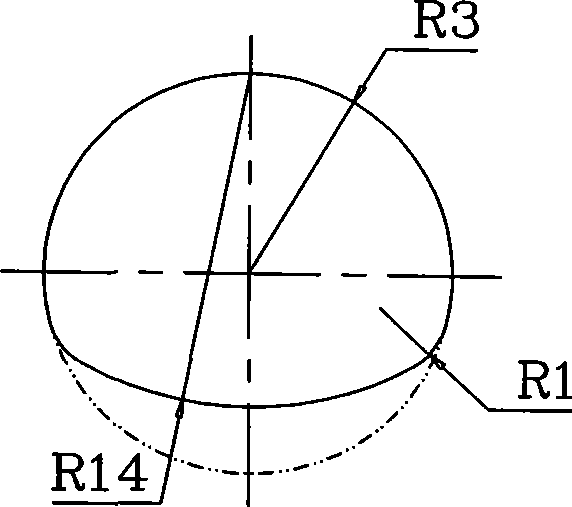

[0017] An example of the present invention is figure 1 , 2 As shown in , 3, it is a single-phase five-speed non-excitation drum tap changer, including an insulator 7, the insulator is an insulating cylinder, a cylindrical fixed contact 4 is arranged on the inner side of the insulator, and insulating terminals are arranged on the upper and lower sides of the insulator Plate 1 is equipped with a main shaft 2 in the middle of the insulating end plates. The upper end of the main shaft is connected to the operating mechanism 3 through a connecting pin. An eccentric support 9 is arranged on the main shaft corresponding to the fixed contact in the axial direction. The support is located on the upper and lower insulating end plates. Between them, a radial sliding pin 8 is installed on the supporting member, a bearing 6 is installed at the front end of the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com