Cluster tool for advanced front-end processing

A kind of equipment and process technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of time-consuming, yield impact, complex problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

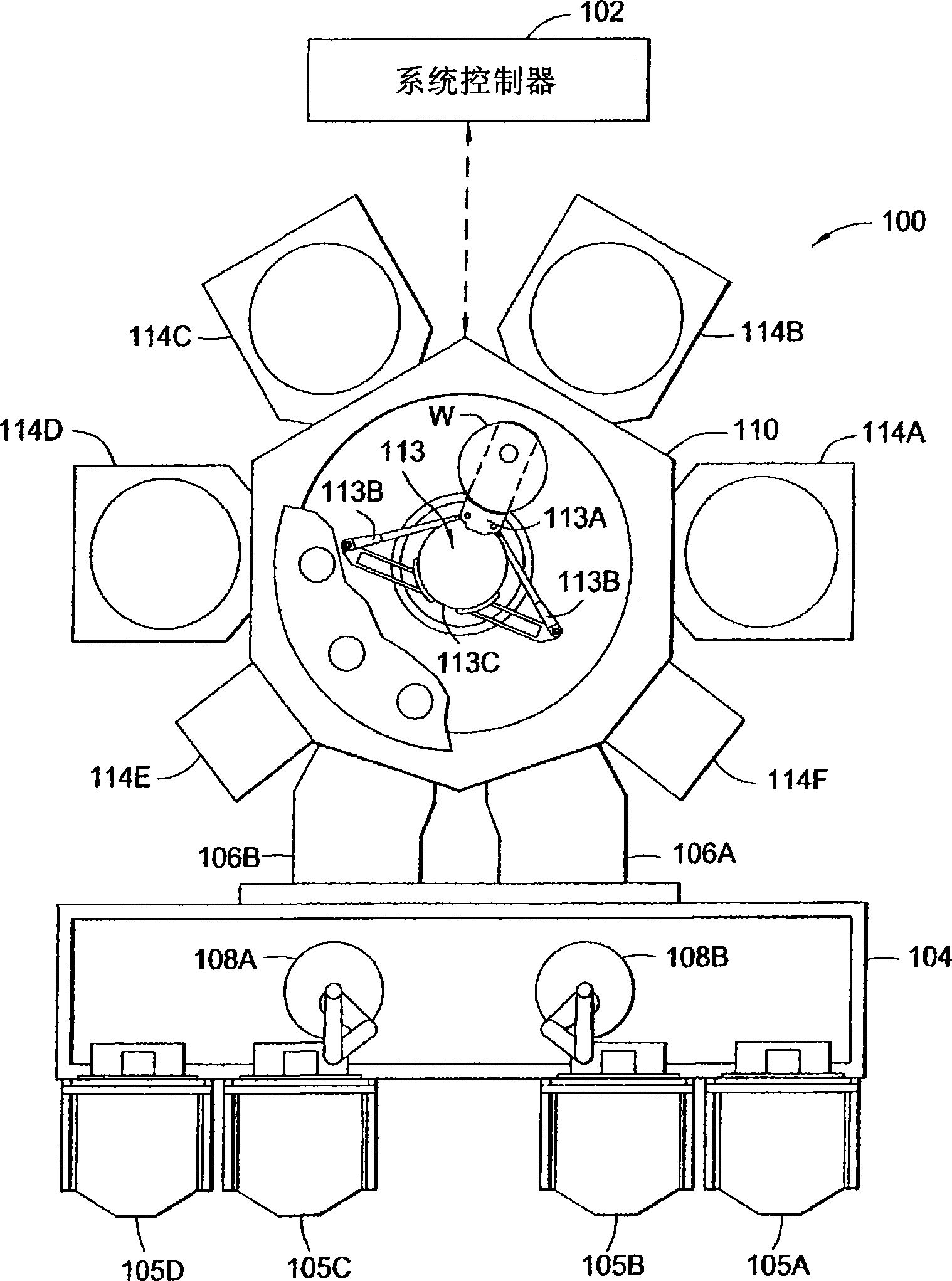

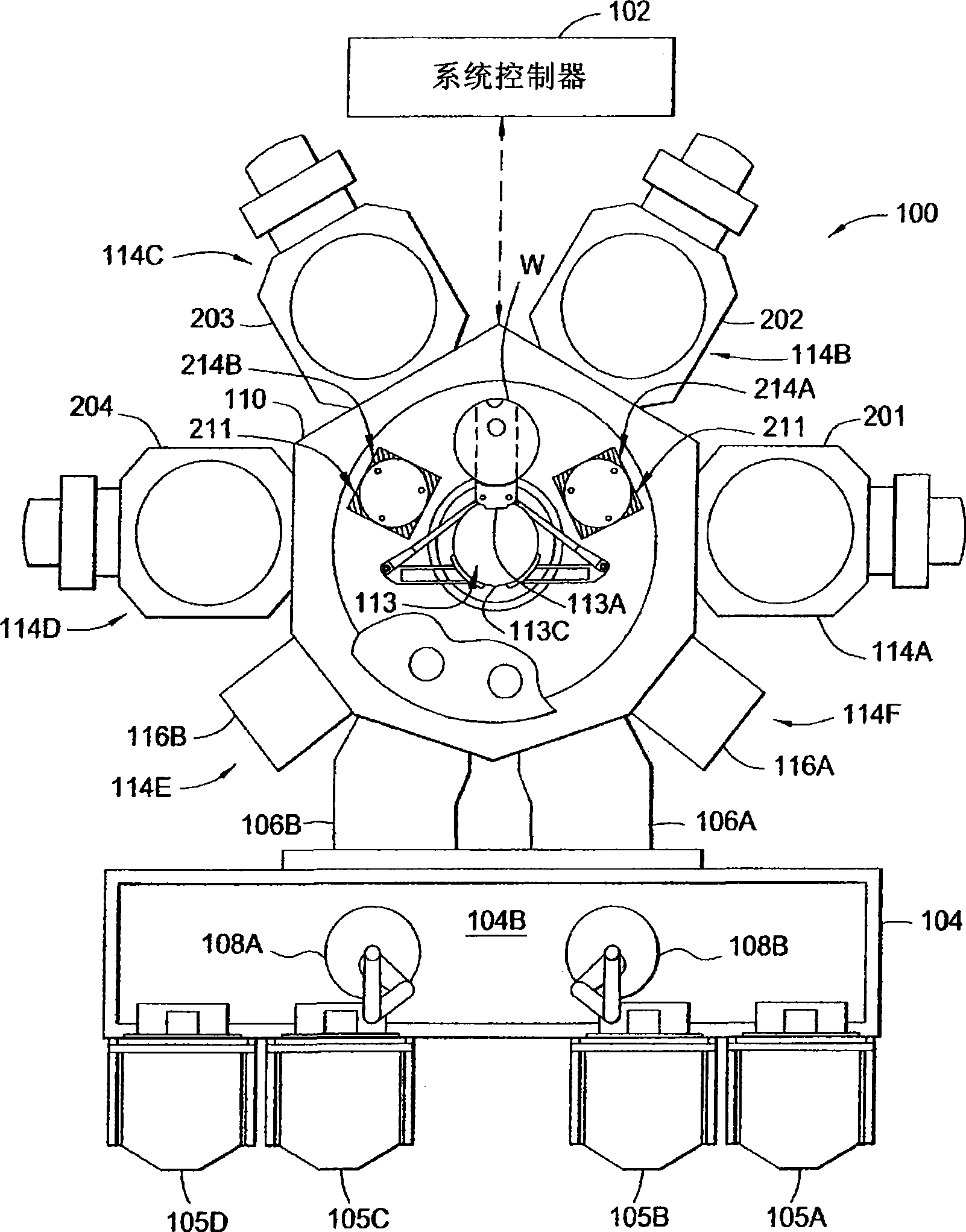

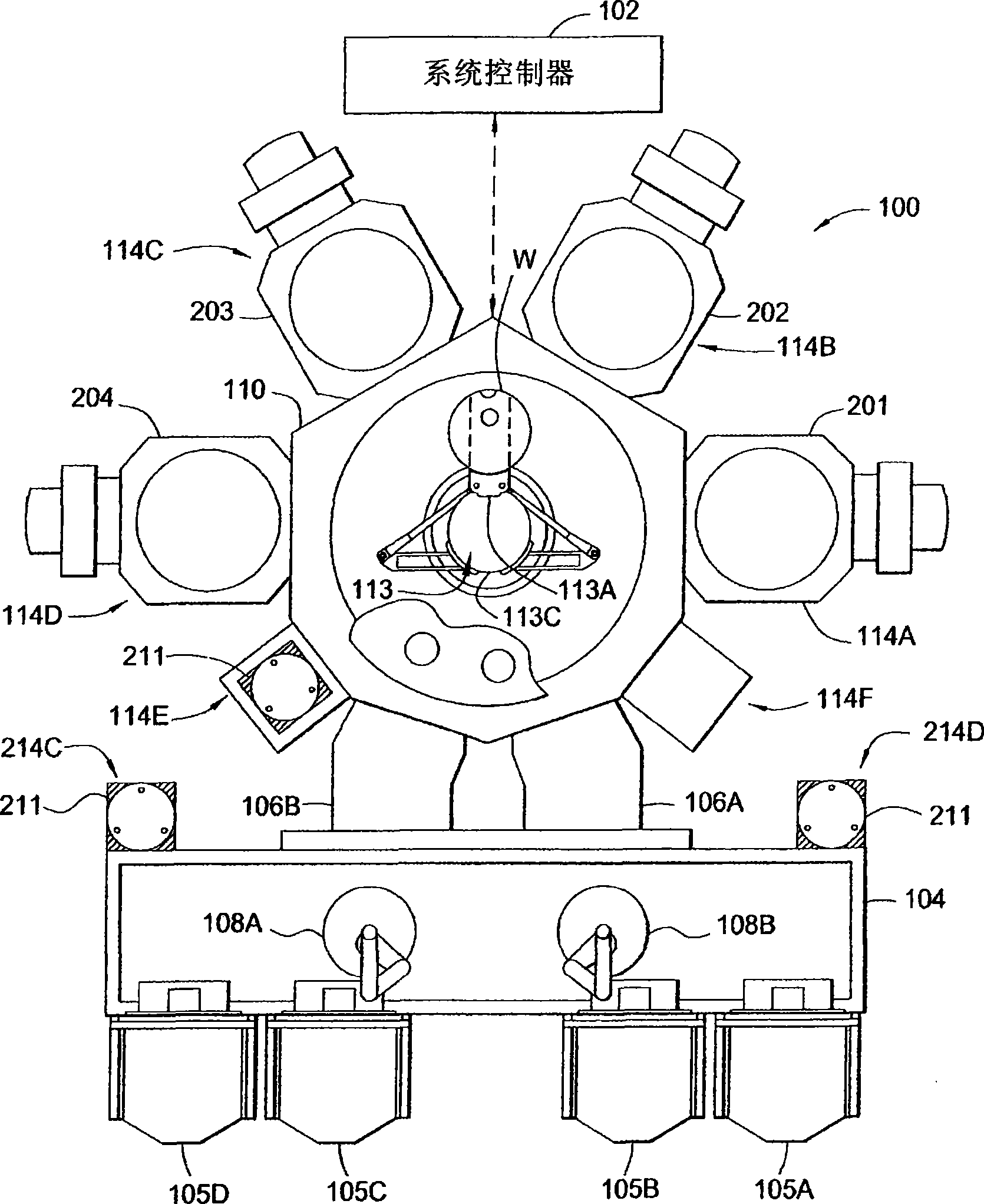

[0072] The present invention generally provides an apparatus and method for processing substrates using a multi-chamber processing system (eg, a cluster apparatus) suitable for processing substrates and analyzing the results of processes performed on the substrates. In one aspect of the invention, one or more analysis steps and / or pre-cleaning steps are used to reduce the impact of waiting time on module yield. In one aspect of the invention, a system controller and one or more analysis chambers are used to monitor and control process chamber recipes and / or process sequences to reduce substrate scrap and component performance due to defects on formed components change problem. Embodiments of the present invention generally also provide methods and systems for repeatable and reliable formation of semiconductor components for use in various applications. The invention is exemplified below with reference to a Centura device available from the FEP division of Applied Materials, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com